Method and system for remotely monitoring laser power of laser device on basis of virtual instruments

A laser power and remote monitoring technology, applied in the field of lasers, can solve the problems of inaccurate detection data, indirect detection methods, uneven distribution, etc., and achieve the effects of system safety and stability, efficient and convenient operation, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

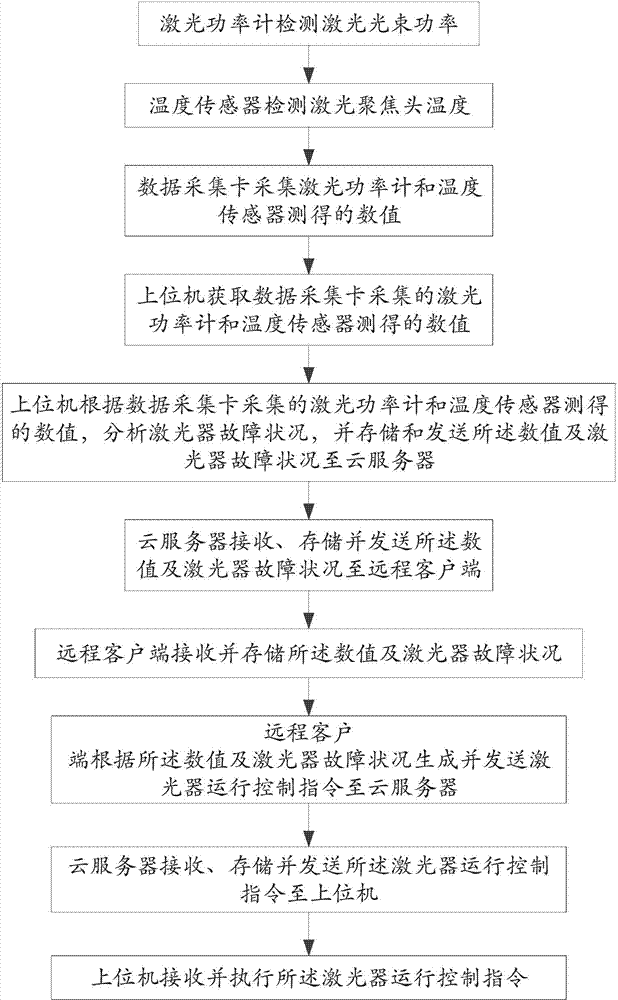

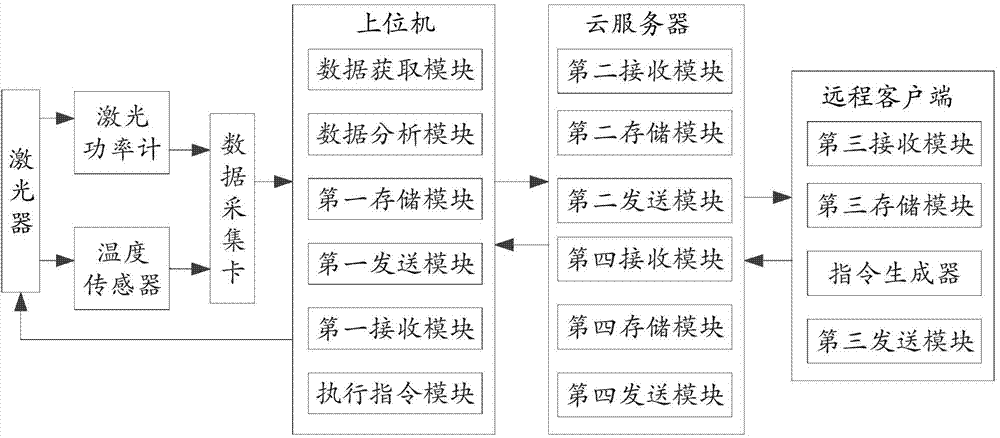

[0103] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0104] A method for remote monitoring of laser power of a laser based on a virtual instrument, the method is:

[0105] The laser power meter detects the laser beam power of the laser and converts the detected laser beam power into a voltage signal;

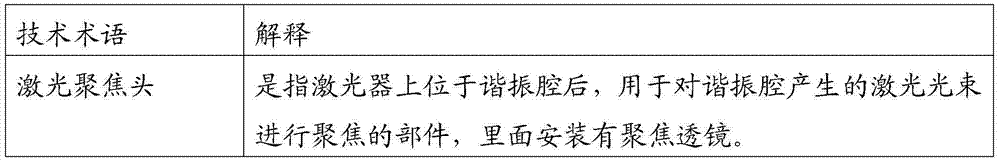

[0106] The temperature sensor detects the temperature of the laser focusing head of the laser, and converts the detected temperature of the laser focusing head into a voltage signal;

[0107] The data acquisition card collects the values measured by the laser power meter and the temperature sensor, and converts the collected voltage signal into a digital signal through A / D conversion;

[0108] The upper computer obtains the values measured by the laser power meter and the temperature sensor collected by the data acquisition card;

[0109] Based on the values measured by the laser power meter and temperature sensor collected by the d...

Embodiment 2

[0119] The laser uses a semiconductor laser, and the laser power meter uses a DH-JG2 power meter with a minimum resolution of 0.001uw, using multiple wavelengths (830nm, 632.8nm, 514.5nm, 488nm, 457.9nm and 441.6nm), and a range from 2uw-200w. According to the relationship between power and output voltage: the power value P is equal to the output voltage V 0 vs. full-scale voltage V max The ratio of is multiplied by the range L:

[0120] P = Vo V max × L

[0121]The upper computer adopts the upper computer program written in the LabVIEW of the American Virtual Instrument Company, and configures the NI-DAQmx read-write control data acquisition card.

[0122] A method for remote monitoring of laser power of a laser based on a virtual instrument, the method is:

[0123] Input laser information, operator, equipment information, warm-up time, acquisition time, acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com