Oil flinger for blower of range hood

A technology for throwing oil pans and range hoods is used in the removal of oil fume, applications, household stoves, etc., which can solve the problems of complicated manufacturing process of winding steel wire, decrease in sound quality, affecting filtration capacity, etc., and achieve high-efficiency centrifugal separation of grease, increase The effect of increasing the degree of action and increasing the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

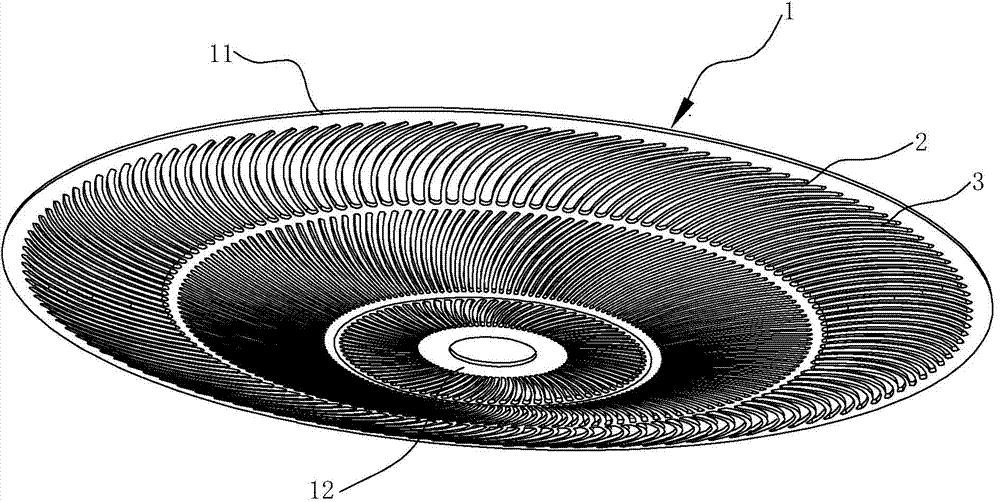

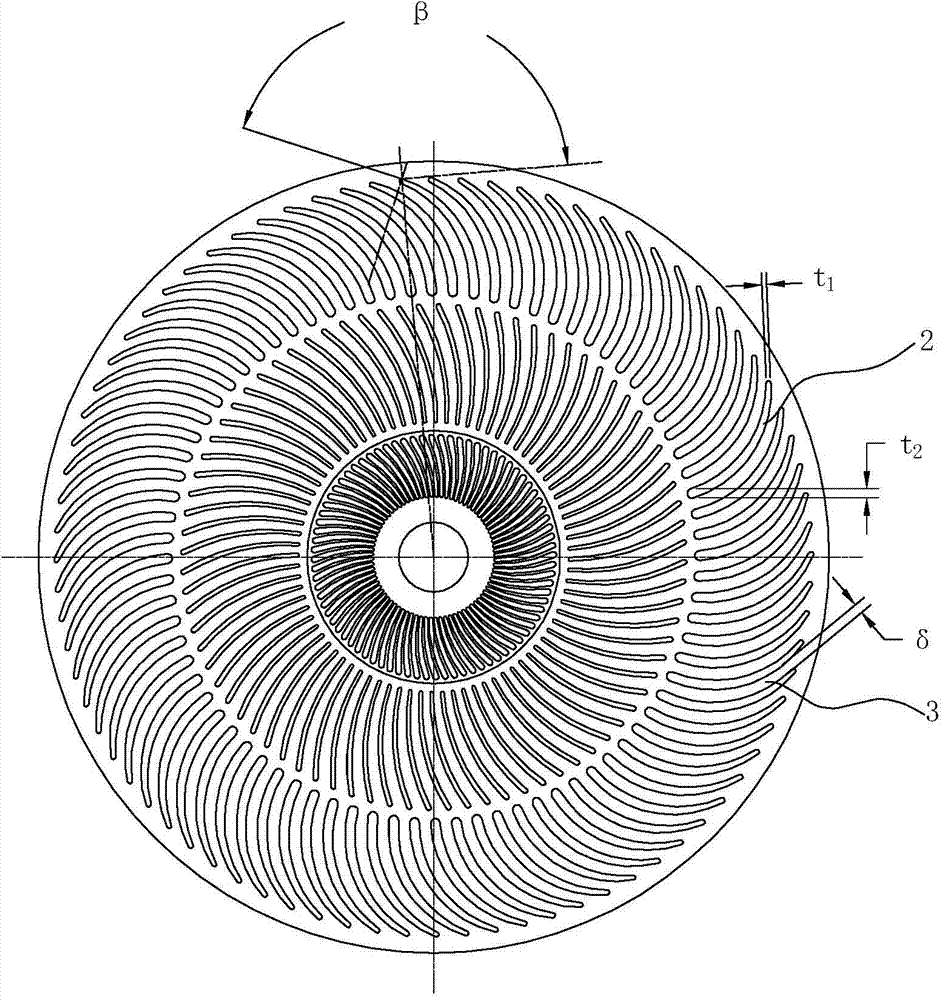

[0019] see Figure 1 ~ Figure 3 , an oil throwing pan used for range hood fans, including a pan main body 1, which can be directly installed at the air inlet of the front end of the impeller of the range hood fan, and placed statically; it can also be located at the front side of the fan impeller, And it is installed on the motor shaft of the fan coaxially with the impeller, and rotates synchronously with the impeller; it can also be connected with the motor separately and installed on the front side of the impeller as a whole. The various usage methods and occasions mentioned above can improve the versatility of the oil flinger of the present invention.

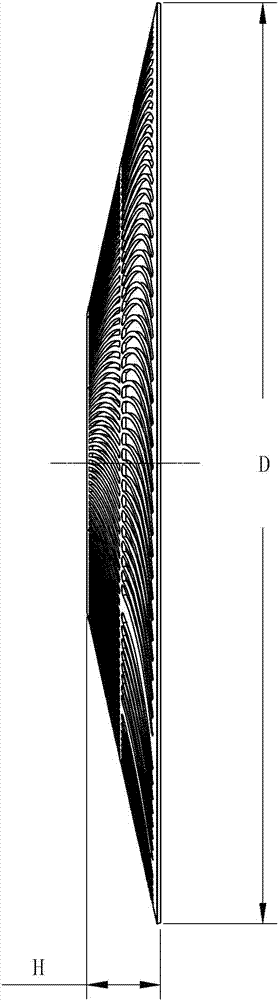

[0020] The disc body 1 has a first end 11 and a second end 12 , and the diameter of the second end 12 is smaller than the diameter D of the first end 11 . In one embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com