Light guide plate for illumination and illuminating lamp

A light guide plate and light-emitting surface technology, which is applied to the light guide, lighting device, lighting and heating equipment of the lighting system, etc., can solve the problems of poor transfer rate, uneven distribution, poor front luminance of the light-emitting plate of the light guide plate, etc. Achieve the effect of improving the transfer rate, uniform lighting light, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

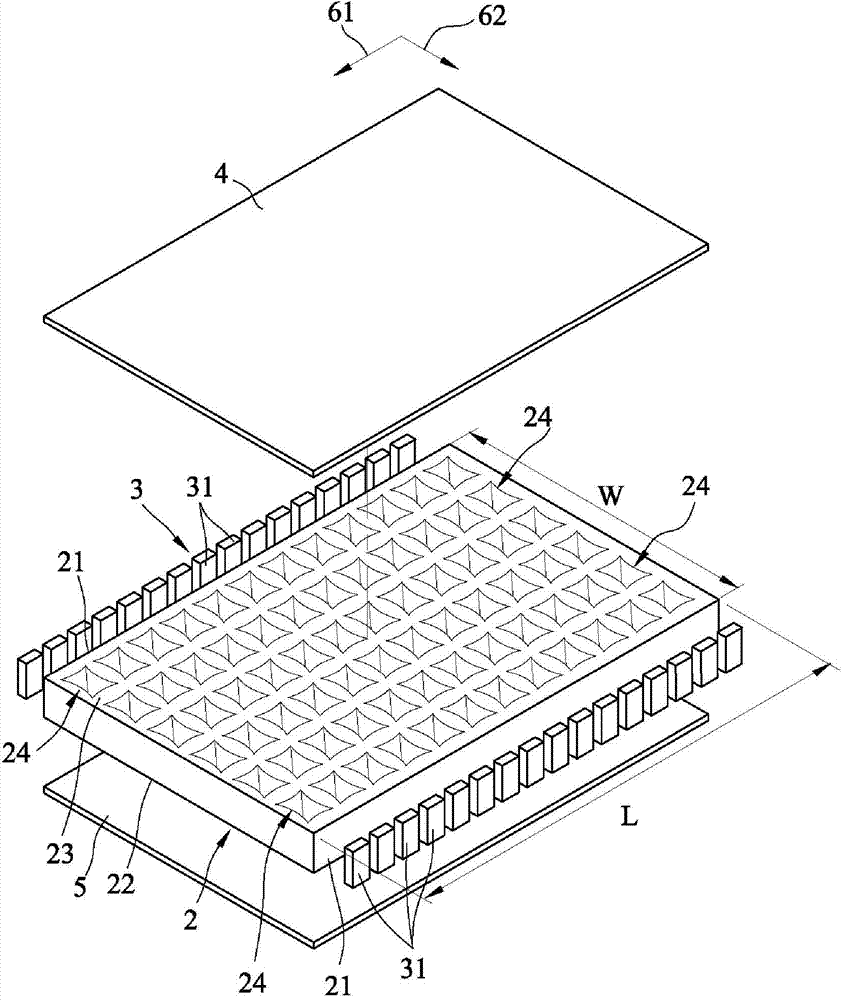

[0037] refer to Figure 3 to Figure 6 , A first preferred embodiment of the lighting fixture of the present invention includes: a light guide plate 2 for lighting, a light emitting unit 3 , a reflecting plate 4 and a diffusing plate 5 . In this embodiment, the lighting direction of the lighting fixture is downward, but the implementation is not limited to this, and it can be changed depending on the application occasion and installation location.

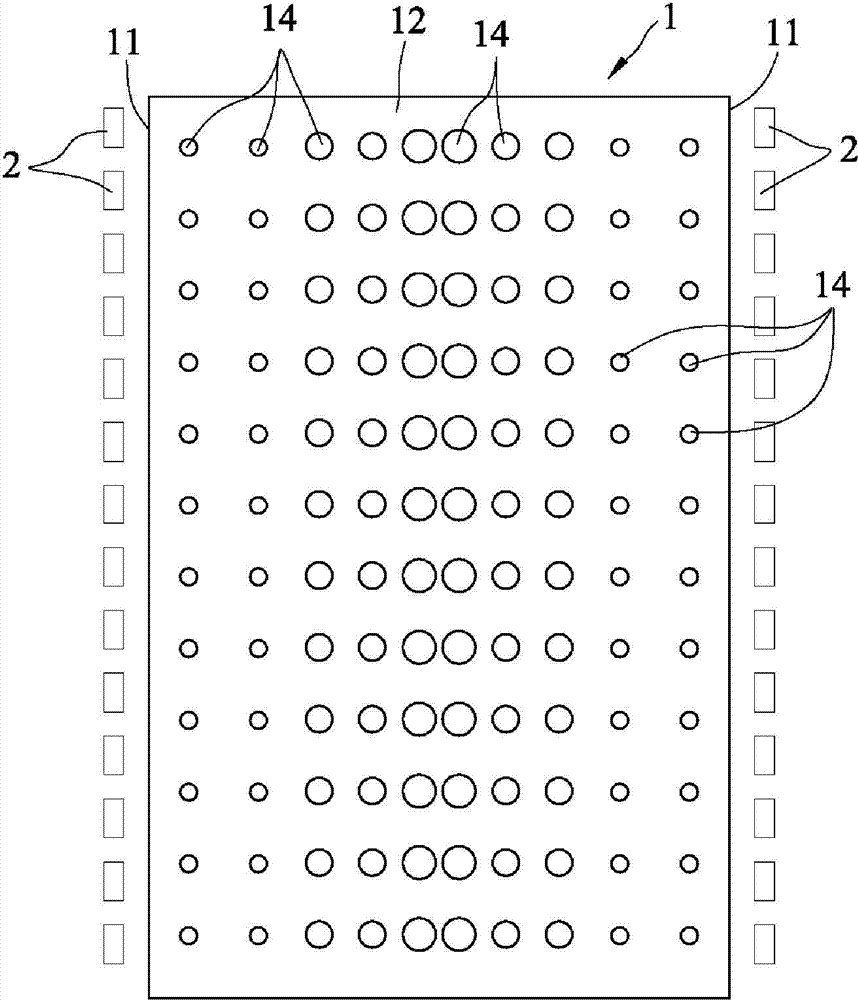

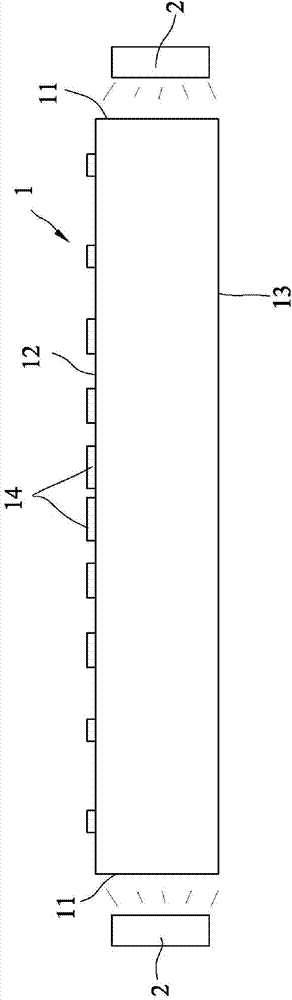

[0038] The light guide plate 2 for illumination comprises: two light-incident surfaces 21 spaced left and right and opposite to each other, a light-exit surface 22 and an inner surface 23 connected between the light-incident surfaces 21 and opposite to each other, and a plurality of the same size and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com