Maintenance-free buckling-free steel-composite material energy-consuming support

A technology of energy-dissipating support and composite materials, which is applied to building components, earthquake resistance, etc., can solve the problems of low maintenance requirements, steel core corrosion, and the inability to completely wrap the steel core surface, etc., and achieve the effect of simplifying the process and excellent energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

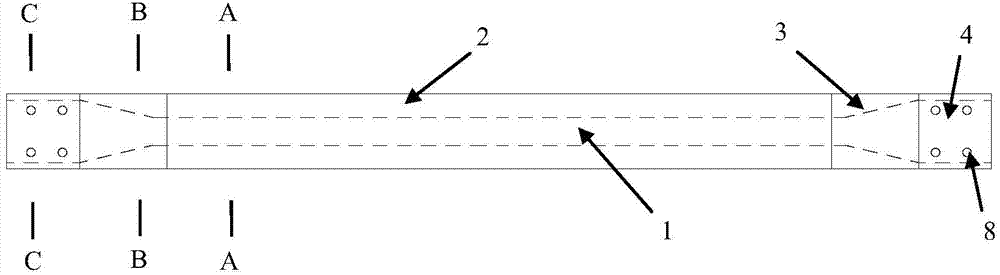

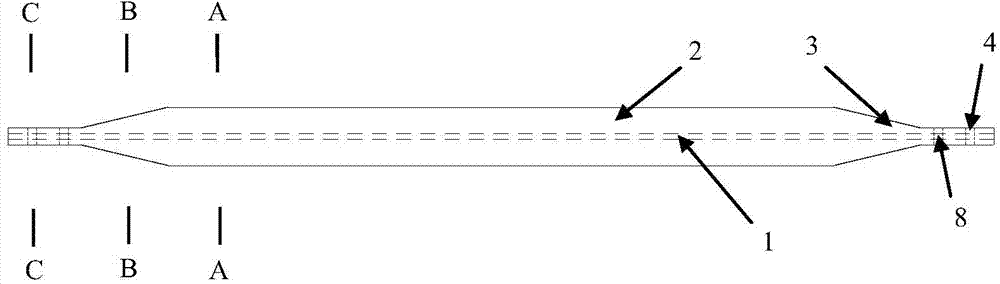

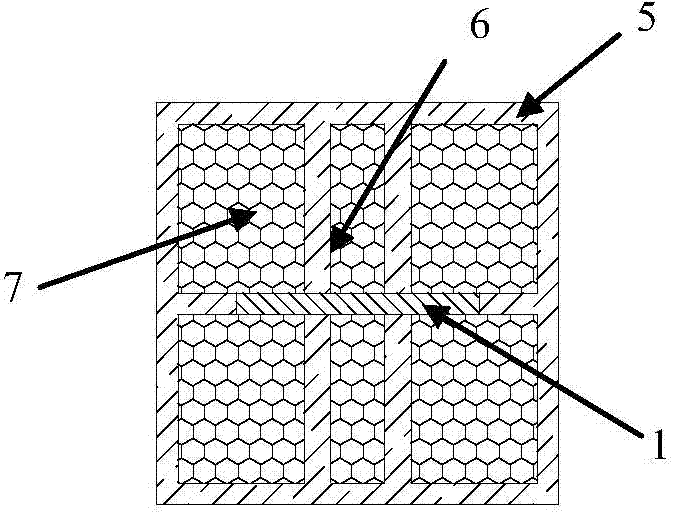

[0019] Such as Figure 1-5 As shown, a maintenance-free non-buckling steel-composite material energy-dissipating support, including energy-dissipating steel core 1, outsourcing GFRP5, GFRP supporting ribs 6 and filling foam 7, the energy-dissipating steel core 1 is in the shape of a line or a cross Runs through outsourced GFRP5;

[0020] The energy-dissipating support is longitudinally divided into a constrained section 2, a flexible section 3 and a connecting section 4, the constrained section 2 is located in the middle, the two sides of the constrained section 2 are flexible sections 3, and the outside of the flexible section 3 is a connecting section 4; Section 2, flexible section 3 and connecting section 4 have the same width; the constrained section 2 has the largest thickness, which is equal to the sum of the thickness of energy-dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com