Sputtering apparatus

A sputtering device and a predetermined position technology, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of different resistivity of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

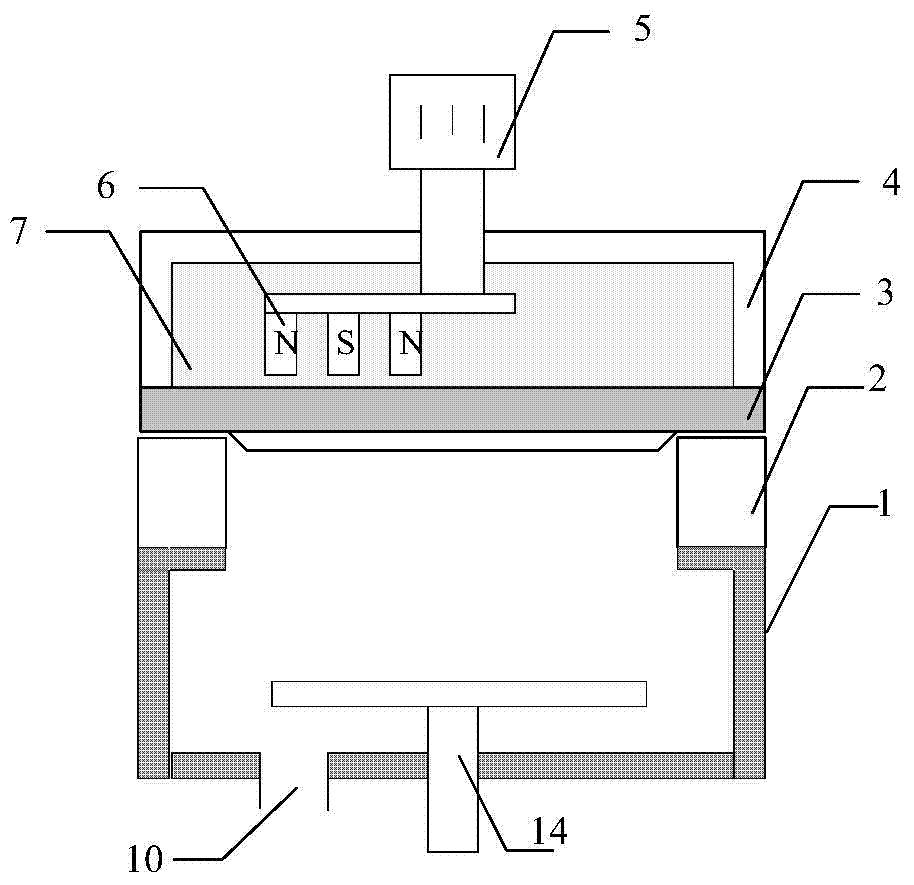

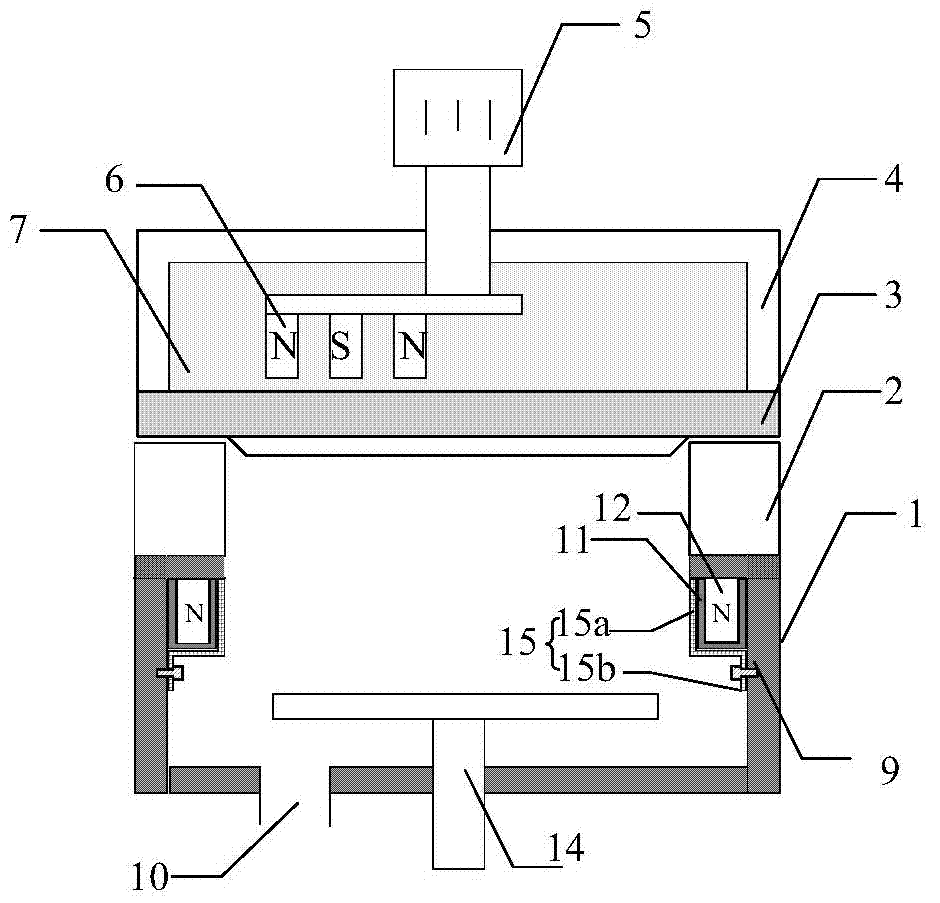

[0042] As the first embodiment of the present invention, such as Figure 4 As shown, the magnetic assembly may include a plurality of magnets 12 and a plurality of housings 15 corresponding to each magnet 12 , and the plurality of housings 15 are disposed around the base 14 . Specifically, a magnet 12 and a spacer 11 covering the magnet 12 are arranged in the accommodation portion 15a of each housing 15, and the mounting portion 15b of each housing 15 is fixed on the inner wall of the process chamber 1 by a fastener 9 superior. In order to evenly distribute the magnetic field strength at the edge of the base 14 , preferably, a plurality of casings 15 are evenly arranged around the base 14 .

[0043] In the sputtering deposition process, the target 3 is bombarded and sputtered, and the sputtered target atoms or molecules move from the surface of the target 3 to the direction of the base 14. At this time, the magnets 12 arranged in the housings 15 The generated magnetic field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com