Dust-containing scorched particle winnowing and separating device and method thereof

A separation device and winnowing technology, which is applied in the direction of swirling devices and devices in which the axial direction of the swirling flow can be reversed, can solve the problems of unsatisfactory separation effect, high manufacturing cost and high operating cost, and achieve wide application value and promotion The effect of value, low manufacturing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The air separation device for dusty coke grains of the present invention will be further described below using the accompanying drawings and examples.

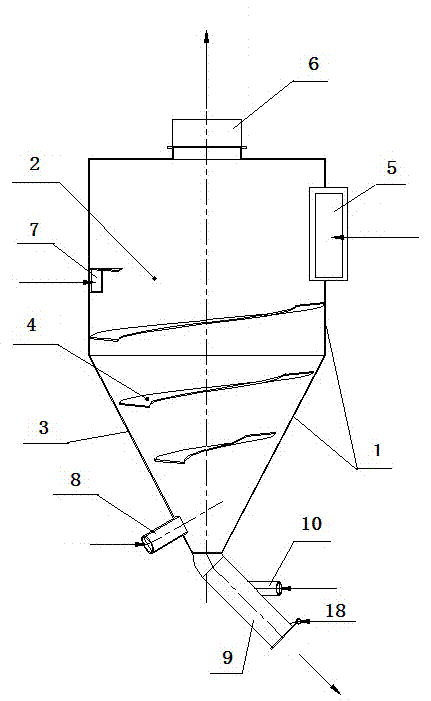

[0021] refer to figure 1 , a wind separation device for dusty coke particles of the present invention, comprising a cylinder 1, the cylinder 1 is composed of a cylinder 2 located above and a conical cylinder 3 located below, and the inner wall of the cylinder 1 A spiral deflector 4 is set on the top, a powder outlet 6 is set on the top of the cylinder 2 of the cylinder 1, an inlet 5 for wind-selected materials is set on the wall of the cylinder 2 of the cylinder 1, and a 2 The initial part of the spiral deflector 4 is provided with an upper air pipe 7, a main air pipe 8 is provided on the side wall of the lower part of the cone 3 of the cylinder 1, and a coarse material discharge pipe 9 is provided at the bottom of the cone 3 of the cylinder 1 , the auxiliary air duct 10 is set on the coarse material discharge pipe 9 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com