Fluorine-containing exhaust gas treatment device and method

A waste gas treatment device and technology for waste gas treatment, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. The effect of reducing calcium content, reducing long-term operating costs, and improving exhaust gas absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

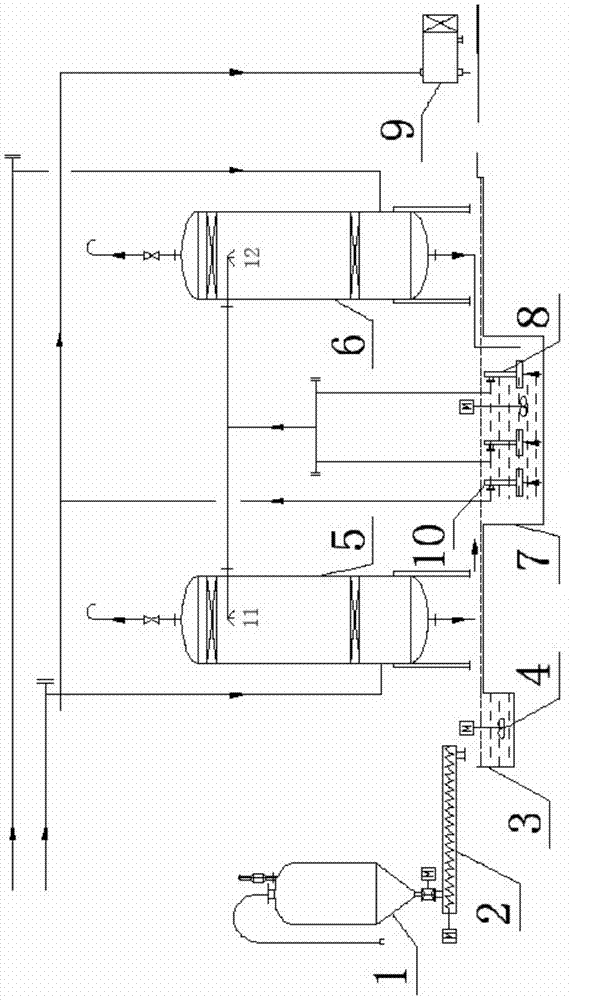

[0088] see figure 1 , a fluorine-containing waste gas treatment device, which includes quicklime storage tank 1, screw feeder 2, lye tank 3, agitator 4, waste gas absorption towers 5 and 6, sediment collection tank 7, waste liquid filter device 9, lye pump 8. Waste liquid pump 10, lye distributor 11 and 12. The lye distributors 11 and 12 made up of lye nozzles are respectively arranged at the radial center above the waste gas absorption towers 5 and 6, and a gas phase distributor (made of Raschig ring fillers) is arranged below the lye distributors. Filling layer with a thickness of 20cm).

[0089] The quicklime (calcium oxide) sent into the factory area is sent to the quicklime storage tank 1 by means of pneumatic conveyance, and the outlet of the lower part of the storage tank is equipped with a frequency conversion screw feeder 2, and the feeding speed is automatically adjusted according to the amount of limestone, and the limestone is fed through a closed channel. Mix wi...

Embodiment 2

[0093] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the tower top lye spray adopts upper and lower two-stage sprays, including the first-stage lye distributor 11 arranged in the waste gas absorption towers 5 and 6 respectively and 12, secondary lye distributors 13 and 14, their respective spray volumes are 1 to 3m 3 / min, the total spray volume is about 3~4m 3 / min, the amount of fluorine-containing waste gas introduced is 30-40m 3 / min, multi-stage purification and absorption of exhaust gas.

[0094] Sampling from the top discharge gas of exhaust gas absorption tower 5 or 6, and analyzing by gas chromatography, the HF content is lower than 0.15mg / m 3 . It shows that the absorption of HF is relatively thorough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com