Method and device for performing combined removal on boiler flue gas particulates and heavy metals

A technology for combined removal and boiler flue gas, applied in combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low removal efficiency, poor hydrophilicity, and inability to remove, and achieve high removal efficiency, Improve adsorption efficiency and efficient mercury removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

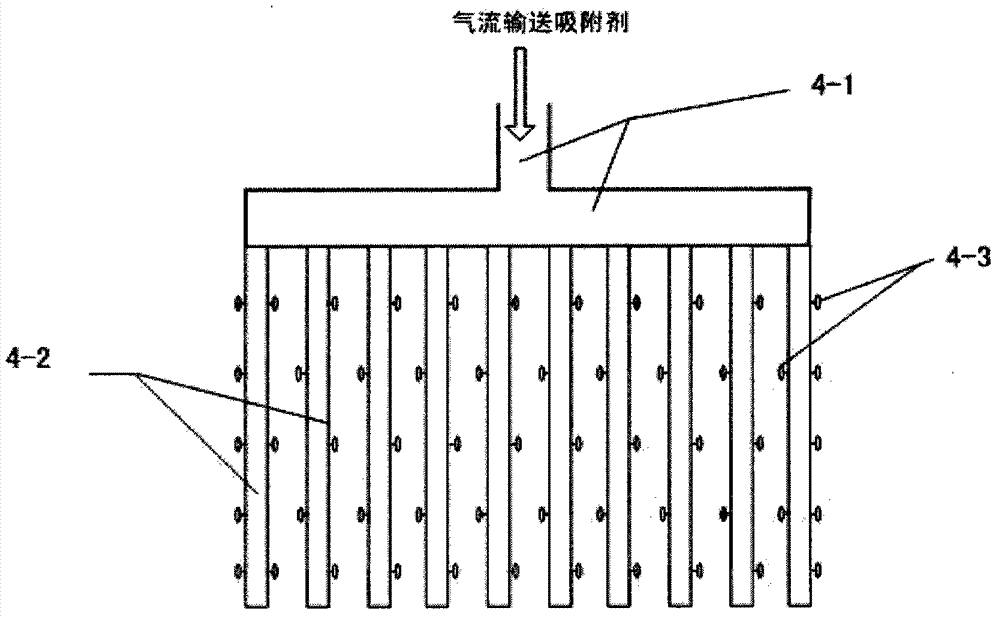

[0015] The method and device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] see figure 1 , a device for joint removal of boiler flue gas particles and heavy metals, along the direction of flue gas flow, in a hollow shell (1), there are successively provided with electric dust removal areas (2), fixed beds of mercury catalytic oxidizers ( 3), the adsorbent injection system (4) and the bag type dust removal area (5); the dust hopper (6) is arranged under the electrostatic precipitator area and the bag type dust removal area. A smoke inlet (7) is arranged on one side of the casing, and a smoke outlet (8) is arranged on the other side of the casing.

[0017] The high-concentration flue gas of the coal-fired boiler first passes through the electrostatic precipitator area (2) for dust removal and filtration to remove most of the particulate matter and some particulate heavy metals, and collects the fly ash particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com