Press type faucet based on pilot structure

A push-type, faucet technology, applied in the valve operation/release device, functional valve type, lift valve, etc., can solve the problems of slow water discharge, laborious pressing, etc., to reduce the opening force, reduce the trouble of manually closing the switch, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

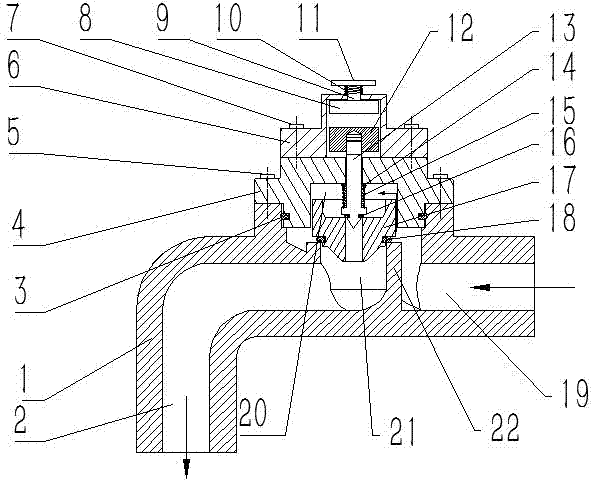

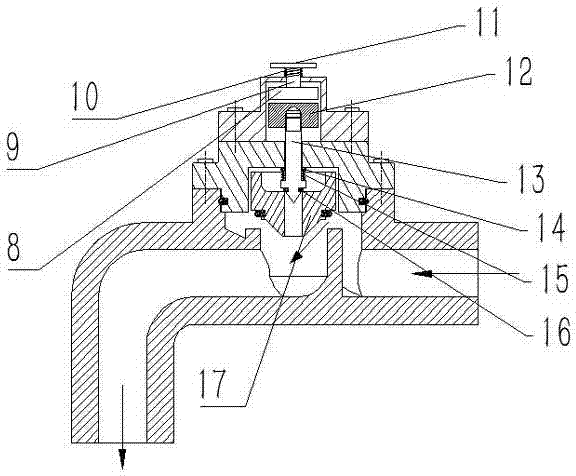

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, this embodiment includes a main body 1, the lower end of the main body 1 is provided with an outlet 2, and the other end on the right side of the main body 1 is provided with an inlet 19; A sealing ring 3 of the main body cover is provided; the upper part of the main body cover 4 is fixedly connected with a pressing device fixing seat 6, and a magnet A8 is arranged in the internal clearance of the pressing device fixing seat 6, and the upper surface of the magnet A8 is threadedly connected with a connecting shaft 9, and the connecting shaft 9 is in clearance fit with the pressing device fixing seat 6, and the other end of the connecting shaft 9 is threadedly connected with a pressing plate 11, and a pressing spring 10 is arranged between the lower surface of the pressing plate 11 and the upper surface of the pressing device fixing seat 6; inside the pressing device fixing seat 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com