An external steel strand mesh device using steel rods to resist tension and prevent continuous collapse of structures

A steel strand and anti-structure technology, which is applied to structural elements, building components, building structures, etc., can solve the problems of low ultimate strength, low efficiency, and affecting the appearance of buildings, so as to improve the performance of anti-successive collapse and device Strong adaptability and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

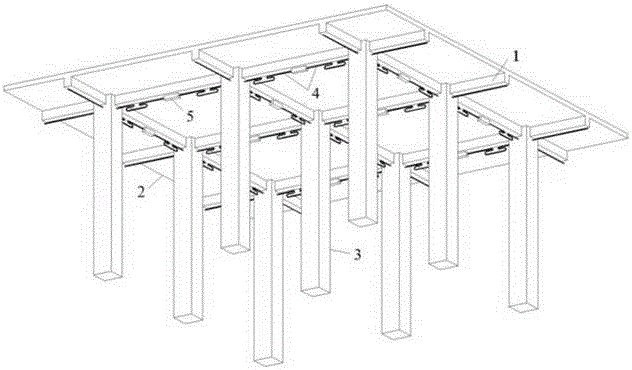

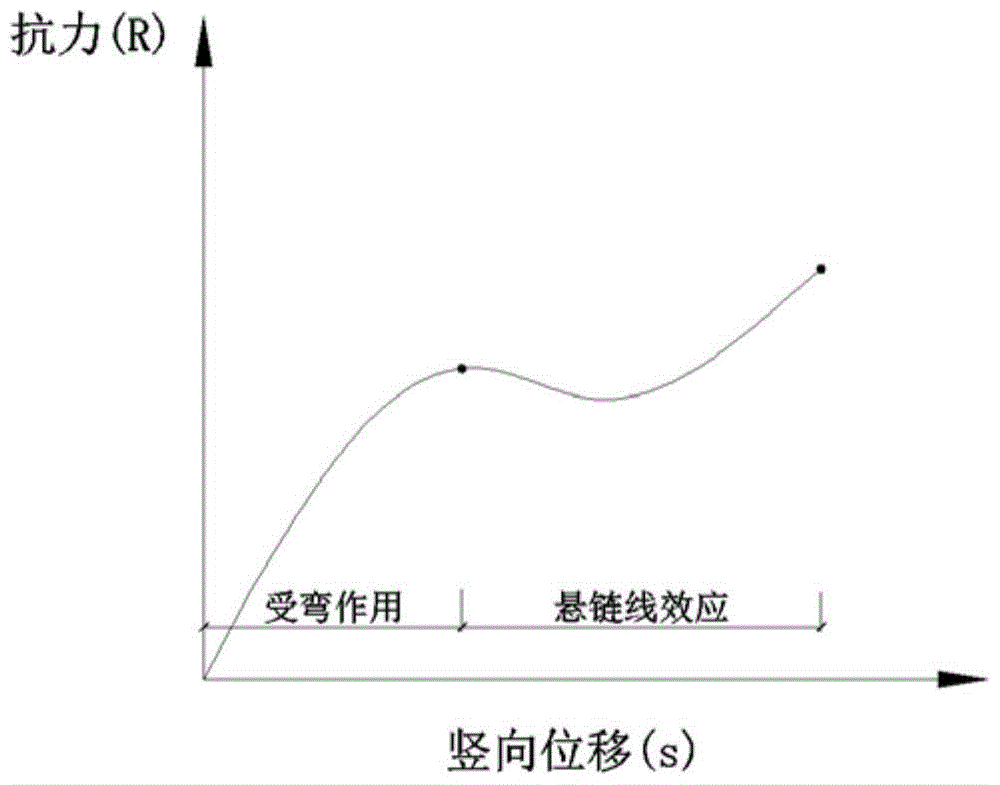

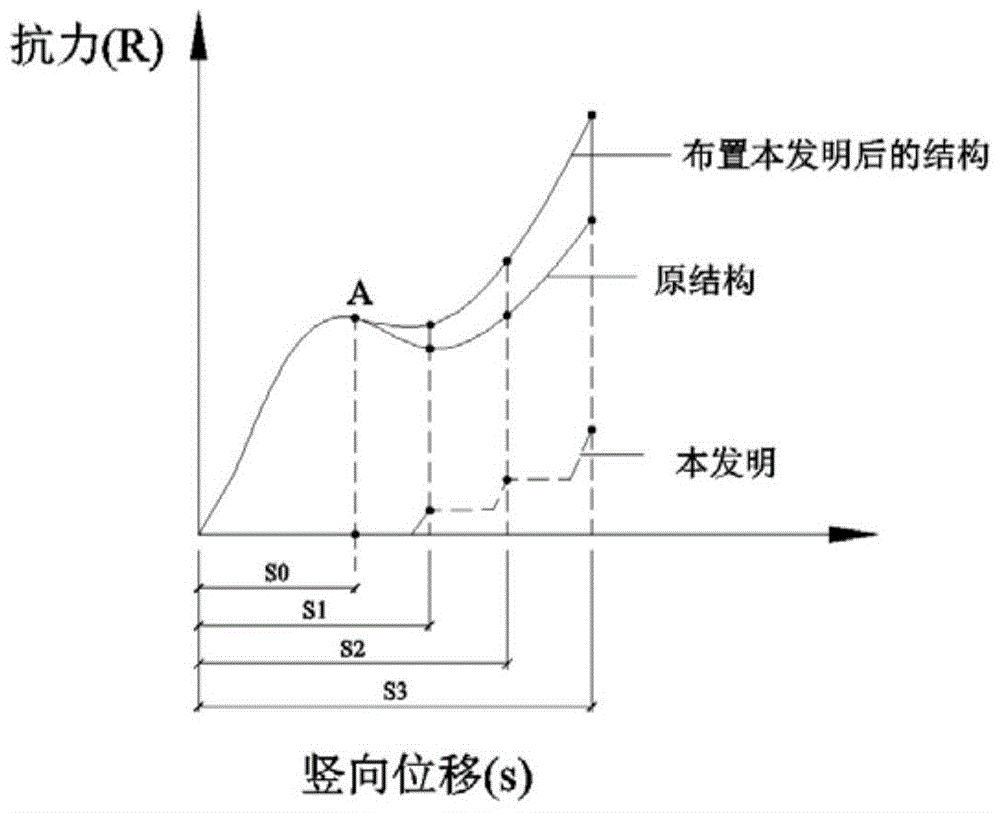

[0033] like image 3 and Figure 4 as shown, image 3 It is a bottom view of the structure of the external steel strand mesh device using steel rods to resist tension and prevent continuous collapse of the structure shown in the embodiment. Figure 4 for image 3The side schematic diagram of the external steel strand mesh device using steel rods to resist the continuous collapse of the structure is shown. An external resistance-adjustable steel strand mesh device for preventing continuous structural collapse, which is composed of several connection units connected in a criss-cross pattern, the connection unit includes two sections of connection lines and connection devices, and the two sections of connection lines pass through the The connecting device is connected to form a connecting unit; the connecting wire is a steel strand 4 . All steel strands run vertically and horizontally in the node area, thus forming a mesh arrangement below the floor. Horizontally and longitu...

Embodiment 2

[0065] A column at the bottom of a reinforced concrete frame structure was damaged by accidental loads. The two vertical adjacent spans are both 5m long, equipped with steel bar 4C14 (C indicates the type of steel bar HRB400) that can produce suspension effect, the standard value of the dead load of the uniform wiring acting on the horizontal member is 5kN / m, and the standard value of the live load of the uniform wiring is 5kN / m. It is 3kN / m, and the ultimate tensile strength of the steel bar is 540MPa. Vertical displacement S at mid-span when the steel bar breaks 3 is 1m, the design value of the maximum vertical uniform wiring load that can be borne is 9.93kN / m.

[0066] In order to improve the resistance against progressive collapse, two sections of 10A are arranged below the beam section S 15.2 (Ultimate tensile strength of 1860MPa) steel strands and a connection box. Two first-level steel rods, two second-level steel rods, and two third-level steel rods in the connectio...

Embodiment 3

[0083] A column at the bottom of a reinforced concrete frame structure was damaged by accidental loads. The two vertically adjacent spans are 9m in average, equipped with 6C25 steel bars that can produce suspension cable effect, the standard value of the dead load of the uniform wiring acting on the horizontal member is 7.5kN / m, and the standard value of the live load of the uniform wiring is 4.5kN / m. The ultimate strength of steel bar is 540MPa. The vertical displacement S at the removal column when the steel bar is broken 3 is 1.8m, and the design value of the maximum vertical uniform wiring load that can be borne is 26.37kN / m.

[0084] In order to improve the resistance against continuous collapse, two sections of 10A are configured S 17.8 (tensile ultimate strength is 1960MPa) steel strand and a connection box. Two first-level steel rods, two second-level steel rods, and two third-level steel rods in the connection box have a circular cross-sectional shape, and the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com