A water inflow control method in the rinsing stage of a drum washing machine

A drum washing machine and water inlet control technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of not considering the number of clothes and water absorption, affecting the rinsing effect, and slow water inlet speed. Long water time, good rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The unit of each symbol in this embodiment adopts the international standard unit.

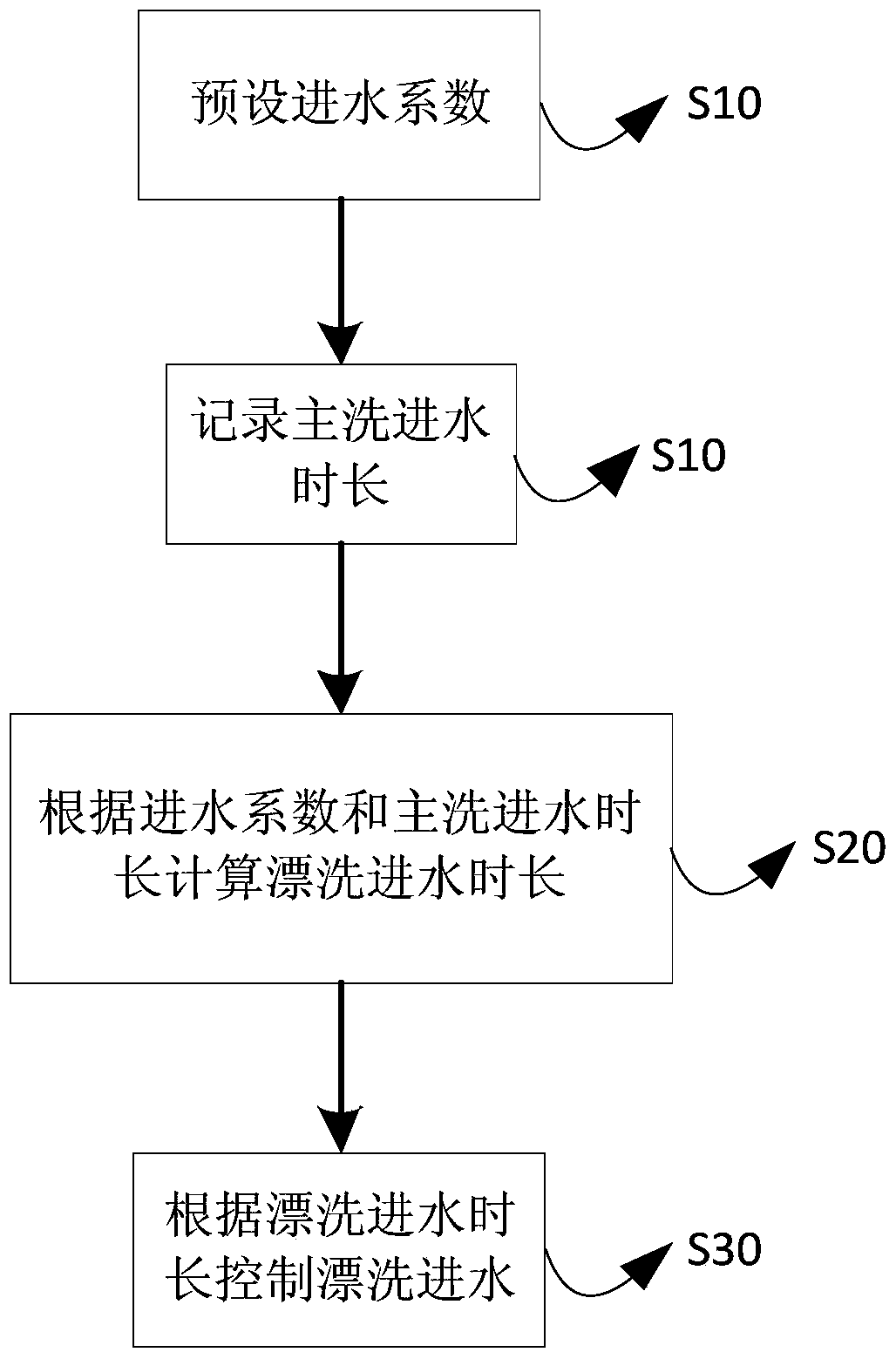

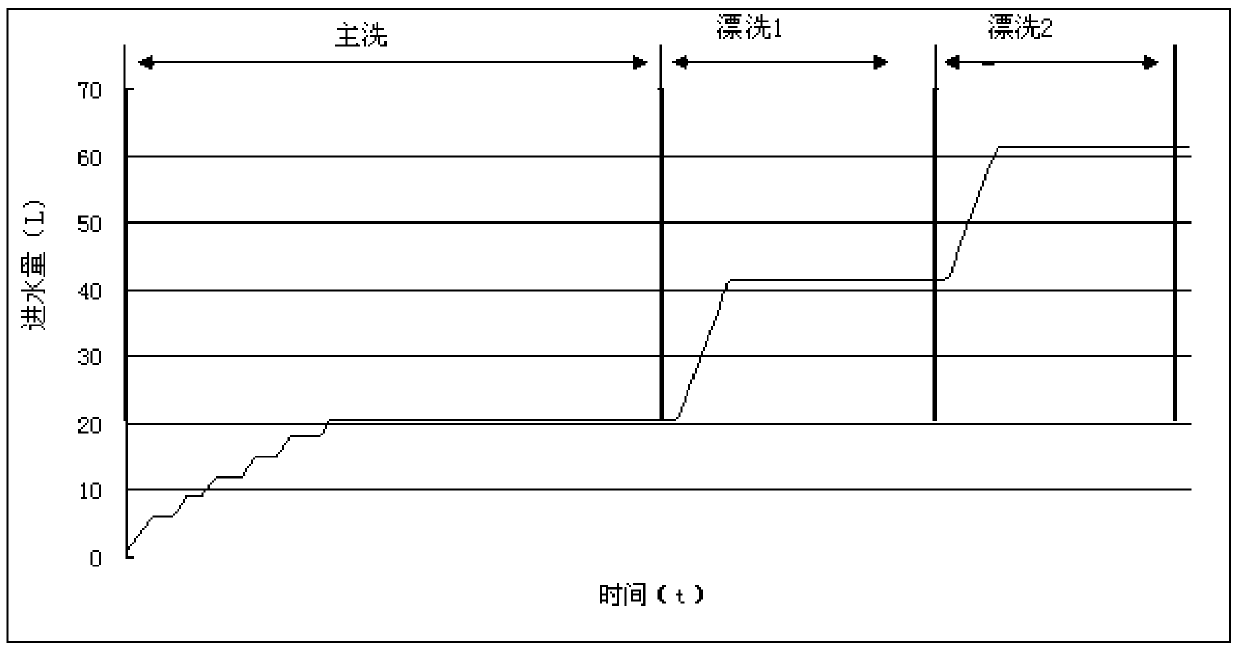

[0037] Such as figure 1 As shown, a method for controlling water inflow in the rinsing stage of a drum washing machine provided in this embodiment includes the following steps:

[0038] Step S00: preset the water inlet coefficient K in the storage unit of the controller of the washing machine p .

[0039] Inlet coefficient K p The calculation formula is as follows:

[0040]

[0041] Among them, L p is the total amount of water inflow during the rinsing stage, L z is the total amount of water inflow during the washing phase.

[0042] That is to say, the ratio of the total amount of water inflow in the rinsing stage to the total amount of water inflow in the washing stage is defined as the water inflow coefficient K p , water ingress coefficient K p It can be considered as a coefficient that does not depend on the amount of clothes and the change of water absorption of clothes...

Embodiment 2

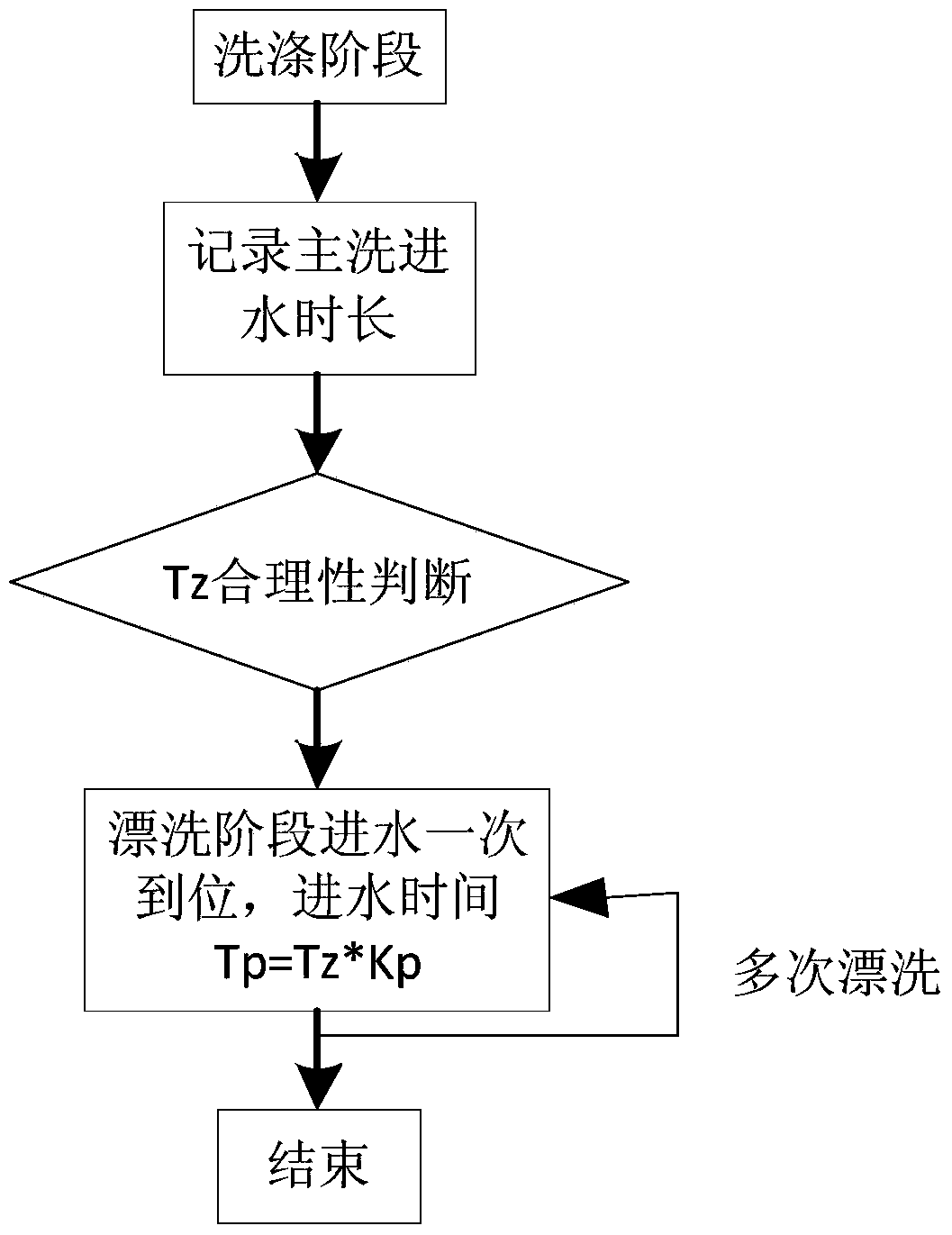

[0059] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is: in order to prevent the water inlet flow F of the solenoid valve a If an abnormality causes the calculation result in step S20 to be inaccurate, after step S10 and before step S20, the main washing water intake time T z Make reasonable judgments.

[0060] The method of rationality judgment is as follows:

[0061] S121: Preset the upper water intake upper limit T of the water intake duration of the washing stage in the storage unit of the controller of the washing machine zmax and the lower limit of water ingress T zmin ;

[0062] S122: The calculation unit of the controller will main wash water for a time T z and water intake upper limit T zmax and the lower limit of water ingress T zmin For comparison, the comparison method is as follows:

[0063] If T zmin z zmax , main wash water intake time T z The value of remains unchanged;

[0064] If T z ≤T zmin , take the time T of...

Embodiment 3

[0070] This embodiment also provides a water inflow control device used in the method for controlling water inflow in the rinsing stage of the drum washing machine in Embodiment 1 or Embodiment 2, including a controller, a water inlet pipe, and a solenoid valve arranged on the water inlet pipe, The solenoid valve is electrically connected with the controller and controlled by the controller. The controller is preferably a single-chip microcomputer system.

[0071] The interior of the controller is provided with a storage unit, a computing unit and an output unit. Among them, the storage unit is used to store the water inflow coefficient K p , upper limit of water intake T zmax And the lower limit of water ingress T zmin The default value related data. The computing unit is used to calculate the water intake time of the main wash T z Make reasonable judgments and calculate the time T of rinsing and water intake p , that is, the calculation process in the above steps is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com