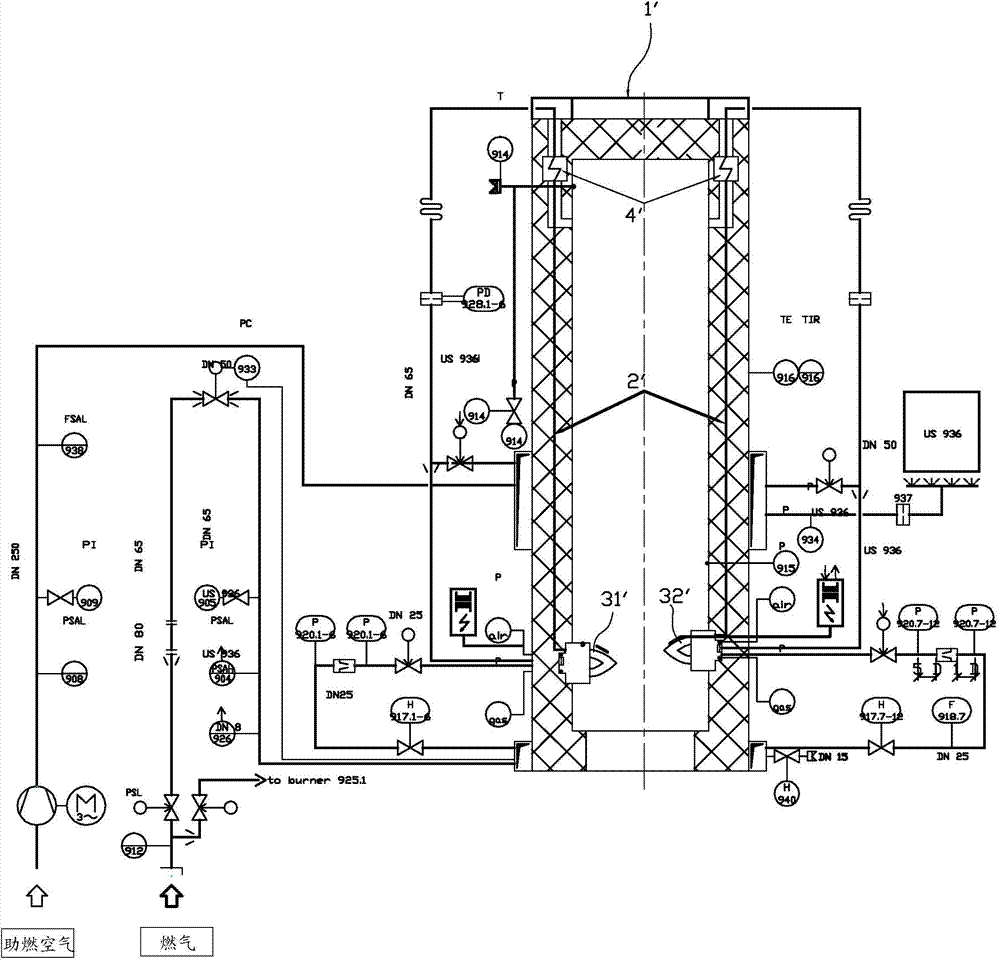

Combustion-supporting air conduit and stainless steel hood-type annealing furnace with same

A technology of combustion-supporting air and stainless steel cover, applied in bell-type furnaces, furnaces, heat treatment furnaces, etc., can solve the problems of cracking of welding seams of combustion-supporting air pipelines, and achieve the effect of reducing maintenance costs, improving efficiency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

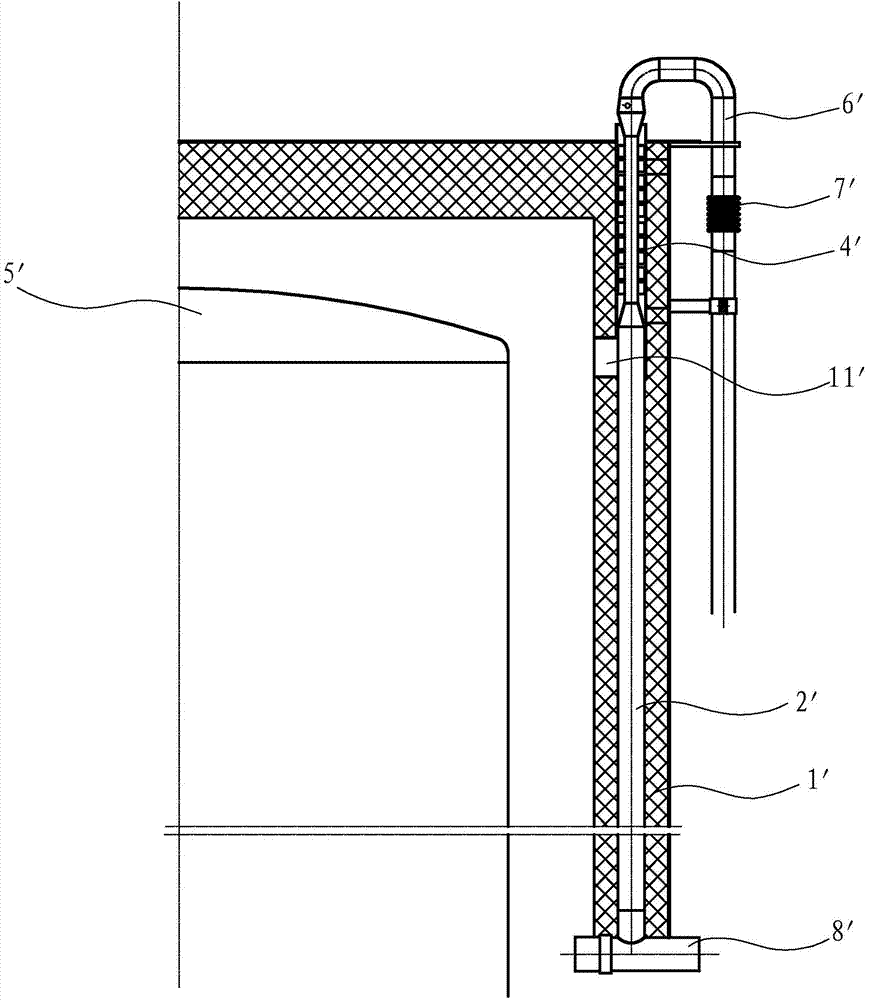

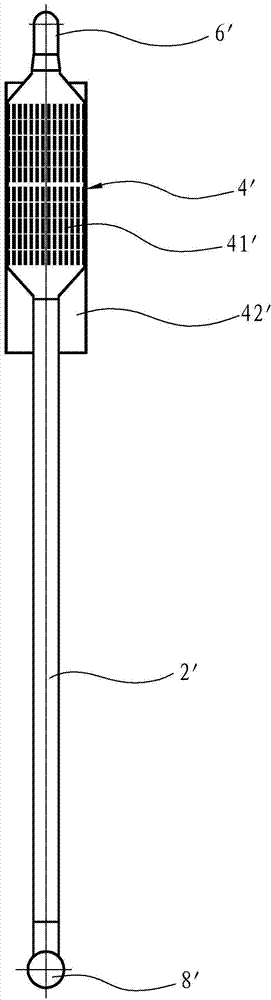

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] like Figures 1 to 8 As shown, the combustion air duct 2 in the embodiment of the present invention includes an upper combustion air duct 21, a lower combustion air duct 22, an upper combustion air duct sleeve 23 and a lower combustion air duct sleeve 24, and the lower combustion air duct sleeve One end of 24 is welded to one end of the lower combustion air pipe 22, and the other end of the lower combustion air pipe sleeve 24 is fitted with one end of the upper combustion air pipe 21. In this embodiment, one end of the upper combustion air pipe 21 is inserted into the lower In the pipe at the other end of the combustion air pipe sleeve 24, one end of the upper combustion air pipe sleeve 23 is welded to one end of the upper combustion air pipe 21, and the other end of the upper combustion air pipe sleeve 23 is connected to the lower comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com