Technology for producing modified pitch by one-step heating

A technology of modified asphalt and production technology, which is applied in the processing of tar, tar processing by distillation, and tar removal processing by water, which can solve the problem of expensive equipment parts, unsecured product quality, and failure to meet export standards. and other problems, to achieve the effect of reducing energy consumption, obvious energy saving effect and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

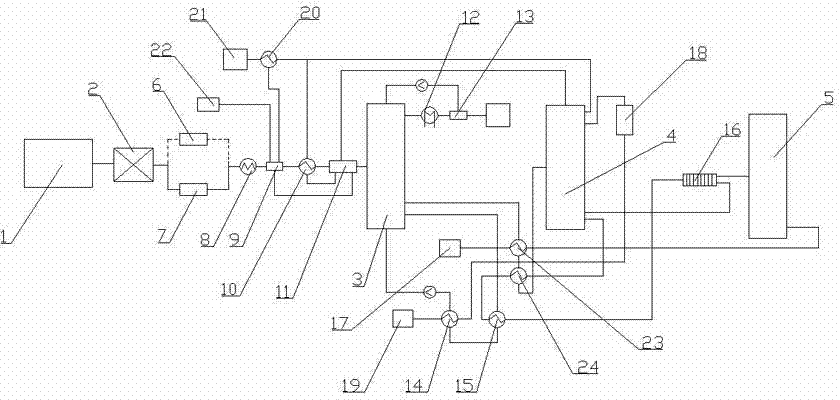

[0023] One-time heating modified asphalt production process, the specific process is as follows:

[0024] 1) Mix the raw material tar with the solvent and then stir evenly. The homogenized tar is pumped into the super centrifuge 2 for separation of light and heavy components through dehydration and deslagging pump, and the separated light and heavy components enter the light component storage tank 6 respectively. and heavy fraction storage tank 7;

[0025] The solvent is washing oil, and the amount of solvent added is 20% of the weight of the raw material tar; the centrifugal force during centrifugation is 3000G, and the centrifugation is 5min. After centrifugation, the quinoline insoluble content of the heavy component tar is greater than 1%, and the quinoline insoluble content of the light component tar is less than 1% is the light component;

[0026] 2) The light component obtained by centrifugation in step 1) is pumped out into the dehydration tar tank, and then pum...

Embodiment 2

[0031] One-time heating modified asphalt production process, the specific process is as follows:

[0032] 1) Mix the raw material tar with the solvent and then stir evenly. The homogenized tar is pumped into the super centrifuge 2 for separation of light and heavy components through dehydration and deslagging pump, and the separated light and heavy components enter the light component storage tank 6 respectively. and heavy fraction storage tank 7;

[0033] The solvent is a 1:1 mixture of light oil and washing oil, and the amount of solvent added is 18% of the weight of the raw material tar; the centrifugal force during centrifugation is 3000G, and the centrifugation is 5min. After centrifugation, the quinoline insoluble content of the heavy component tar is greater than 1%, and the quinoline insoluble content of the light component tar is less than 1% is the light component;

[0034] 2) The heavy components obtained by centrifugation in step 1) are pumped out into th...

Embodiment 3

[0039] One-time heating modified asphalt production process, the specific process is as follows:

[0040] 1) Mix the raw material tar (the raw material tar is in the raw material tar storage tank 1) with the solvent, then stir and homogenize, and the homogenized tar is sent to the super centrifuge 2 by dehydration and deslagging pump for separation of light and heavy components, and the separated The light and heavy components enter the light component storage tank 6 and the heavy component storage tank 7 respectively;

[0041] The solvent is light oil, and the amount of solvent added is 15% of the weight of the raw material tar; the centrifugal force during centrifugation is 3000G, and the centrifugation is 2min. After centrifugation, the quinoline insoluble content of the heavy component tar is greater than 1%, and the quinoline insoluble content of the light component tar is less than 1% is the light component;

[0042] 2) The light components obtained by centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com