Process system for preparing glycyl glutamine and method thereof

A technology of glycylglutamine and process system, which is applied in the field of glycylglutamine process system, can solve the problems of high synthesis cost, inability to realize industrialized production, and high raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

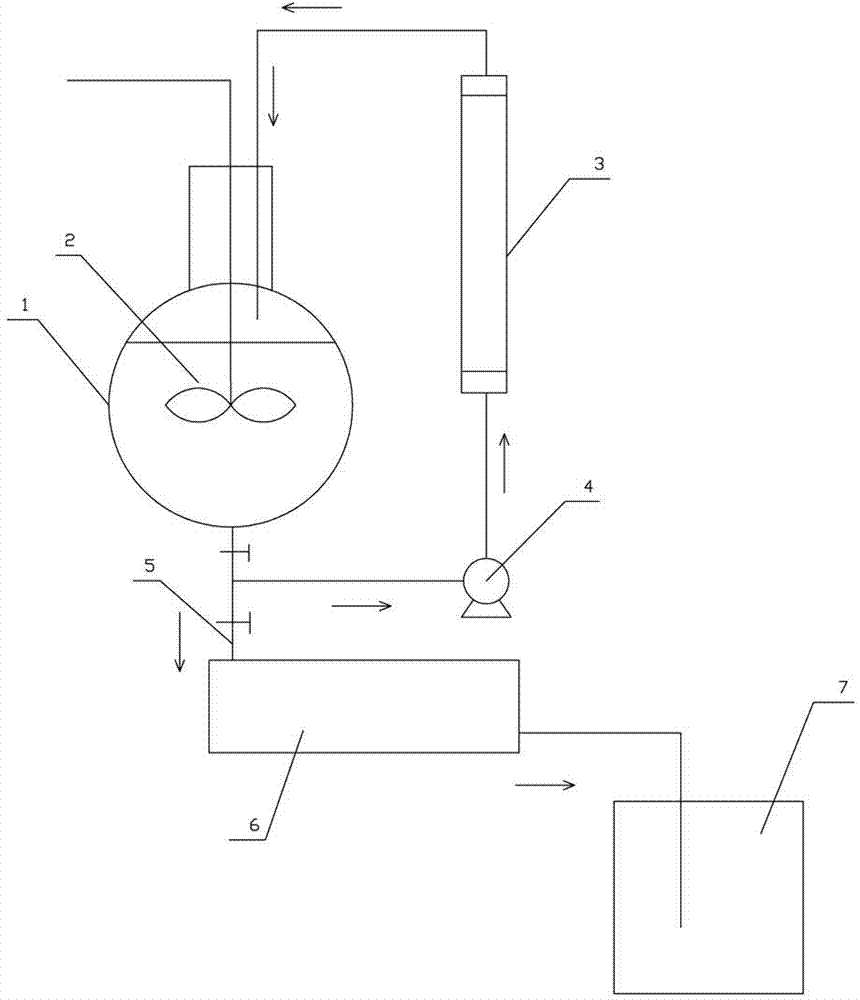

[0017] Such as figure 1 As shown, a process system for preparing glycylglutamine includes a reaction device 1, a stirring device 2, a filter column 3, and a pump 4; the stirring device 2 is located in the synthesis reaction device 1; the reaction There is an outlet at the bottom of the device 1, and the outlet is connected to a tee. The other two ports of the tee are respectively connected to the liquid outlet 5 and one end of the pump 4. It also includes a filter device 6, a collection device 7, and the filter device 6 The upstream end is connected to the outlet end 5 with a pipeline, and the downstream end of the filtering device 6 is connected to the collection device 7 in a pipeline.

[0018] In this embodiment, the filter device 6 is an ultrafiltration device; the filler in the filter column 3 is activated carbon.

[0019] A method using the process system for preparing glycylglutamine according to claim 1, wherein the pump 4 pumps the reaction liquid in the reaction device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com