Direct drive type reversible wafer transmission robot

A robot, direct-drive technology, applied in conveyor objects, manipulators, transportation and packaging, etc., can solve the problems of different shafts, complex structure, difficult installation, etc., to achieve high transmission accuracy, simple electrical control, improved The effect of cleanliness class

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings.

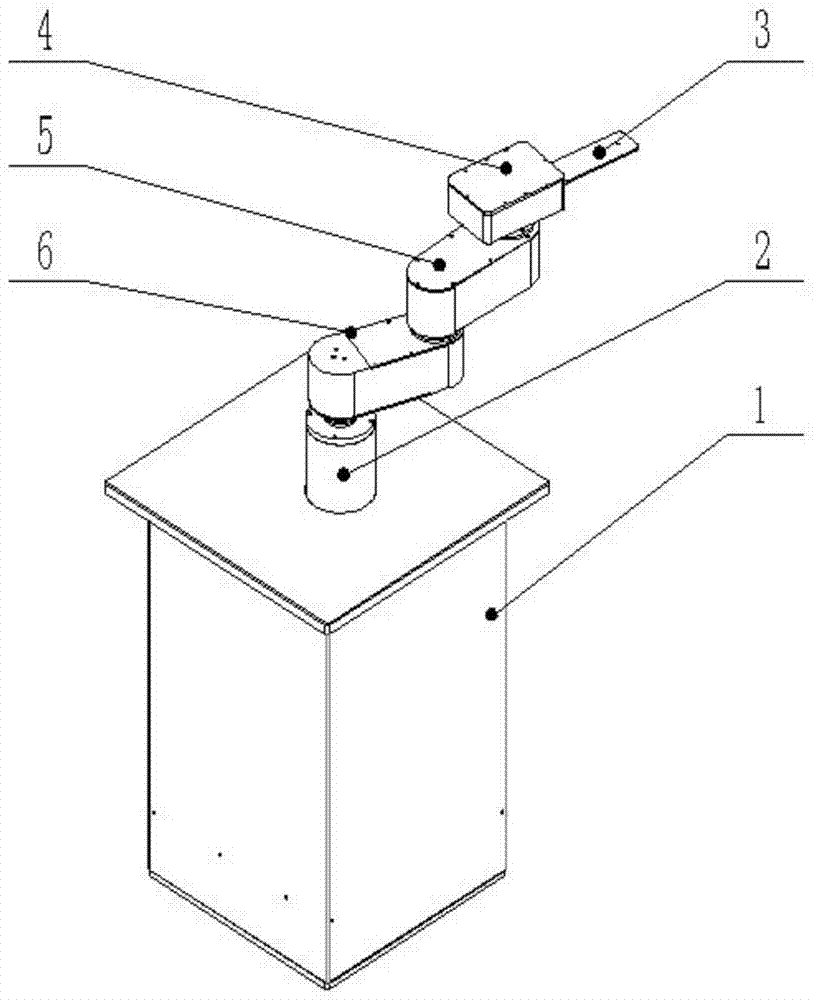

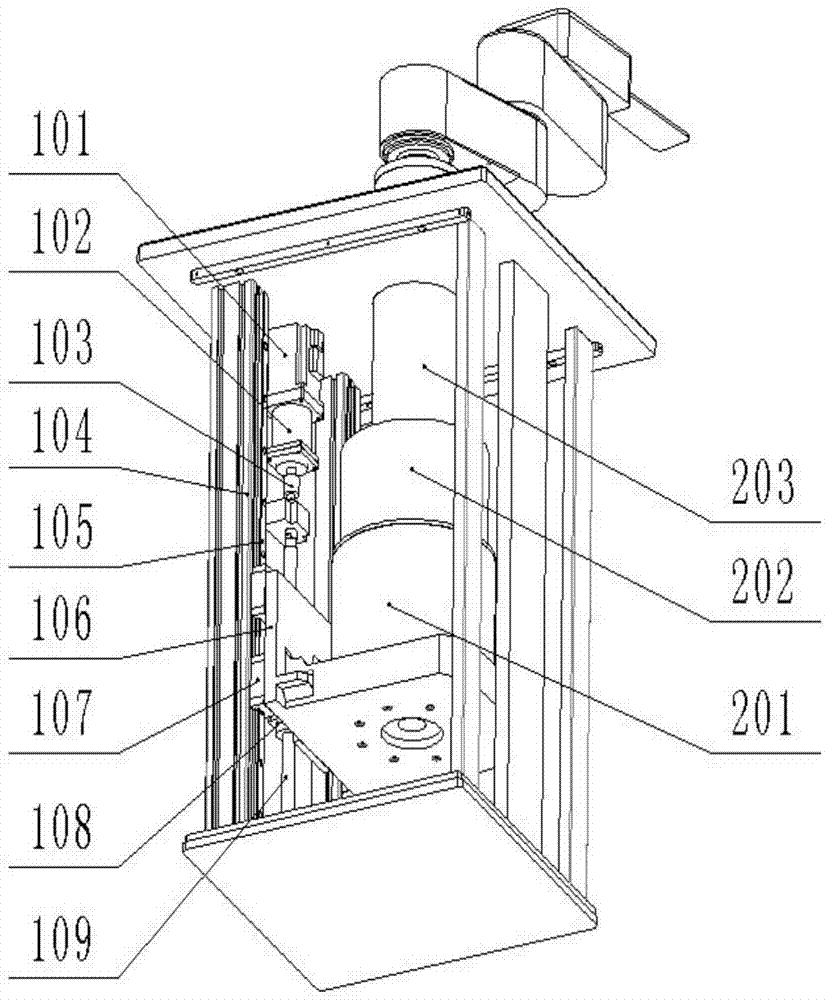

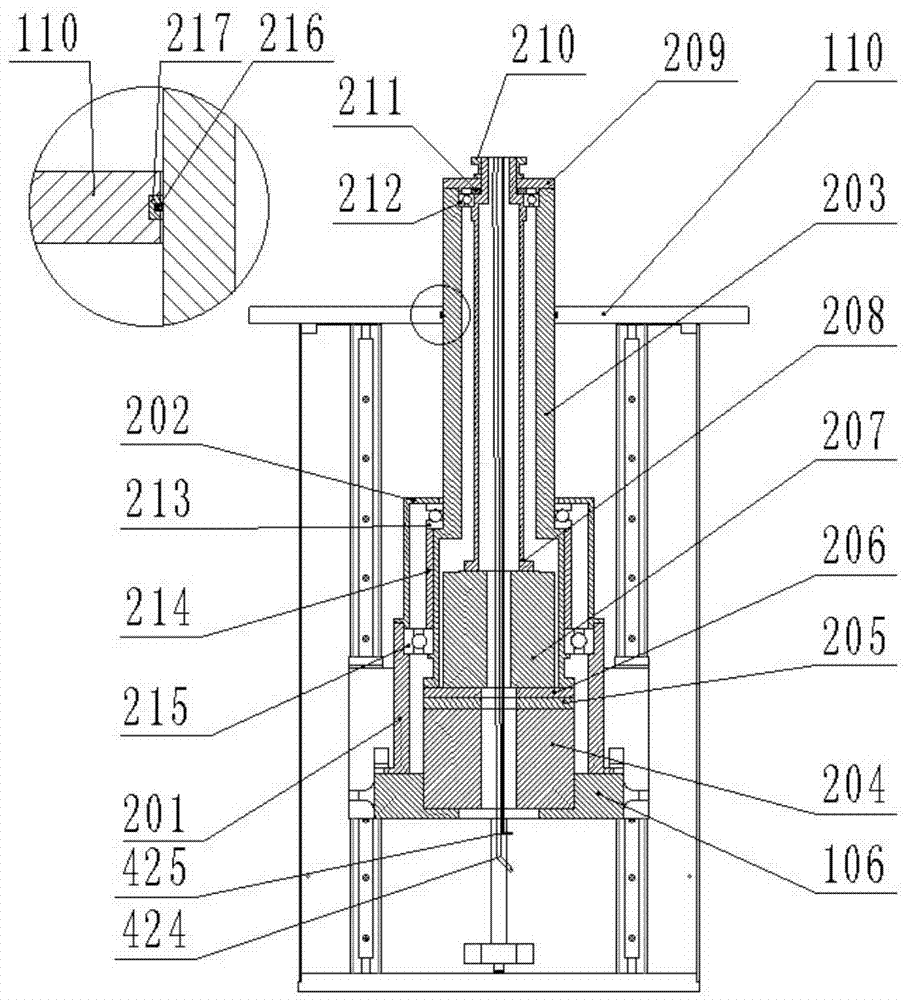

[0040] Such as Figure 1-6 As shown, a direct-drive reversible wafer transfer robot includes a base 1, a lifting and rotating mechanism 2, a vacuum suction end 3, a turning wrist 4, a small arm 5 and a large arm 6; the base 1 Lifting and slewing mechanism 2 is installed inside, and lifting and slewing mechanism 2 is connected with boom 6 one end (near end), and boom 6 other end (far end) is connected with forearm 5 one end (near end), and forearm 5 other end (near end) The far end) is connected with one end of the turning wrist 4, and the other end of the turning wrist 4 is connected with the vacuum suction end 3.

[0041] When the wafer transfer robot moves, the base 1 is fixed, and the lifting and rotating mechanism 2 can rotate around the center of the base 1, and can also perform lifting motion along the vertical direction (Z direction) of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com