Trapezoidal ridge shaping device

A technology of shaper and trapezoidal ridge, applied in the field of trapezoidal ridge shaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

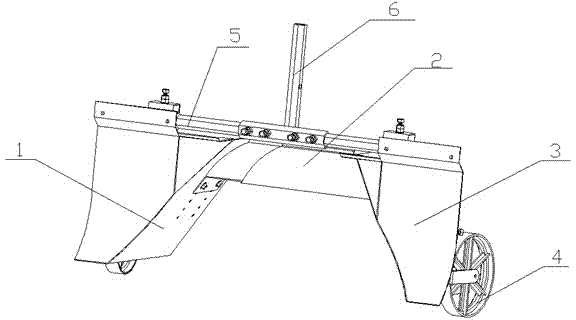

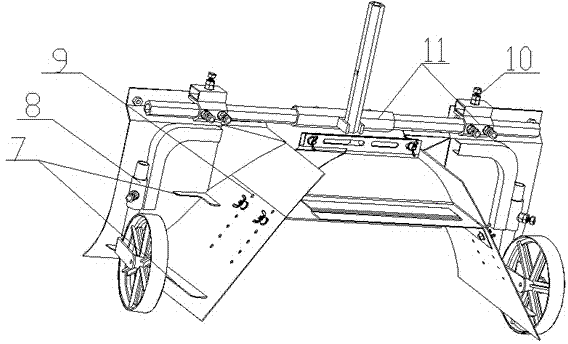

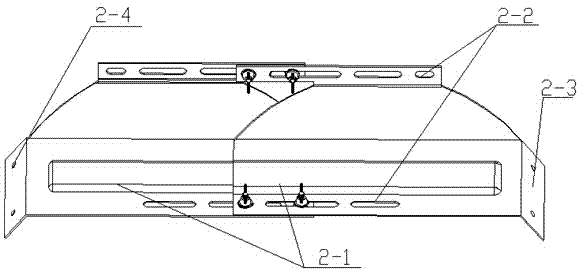

[0016] figure 1 and figure 2 As shown, a trapezoidal ridge shaper includes a shaping side plate 1, an adjusting top plate 2, a soil-building plate 3, an adjusting wheel 4, an adjusting conduit 5, a hooking device 6, a reinforcing plate 7, an adjusting rod 8, a circular hole 9, Jack nut 10, hexagonal socket 11. A hooking device 6 is set in the middle of the adjusting guide tube 5, and the hooking device 6 can be adjusted along the adjusting guide tube 5 to select a hooking position. The two ends of the adjustment conduit 5 are connected to the hexagonal conduit 11, and the hexagonal sleeve 11 can be adjusted along the adjustment conduit 5 to adjust the width of the two sleeves. The hexagonal pipe sleeve 11 adopts a hexagonal steel pipe, which can ensure that the working part does not turn over. Shaping side plate 1, earthing plate 3, circular hole 9, hexagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com