Resistive grain moisture measurement system

A technology of grain moisture and detection system, applied in the direction of preservation of seeds by drying, material resistance, etc., can solve the problems of inability to automatically control, reduce drying efficiency, energy waste, etc., to improve accuracy, improve temperature linearity, and achieve high efficiency Effects of Sexuality and Precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

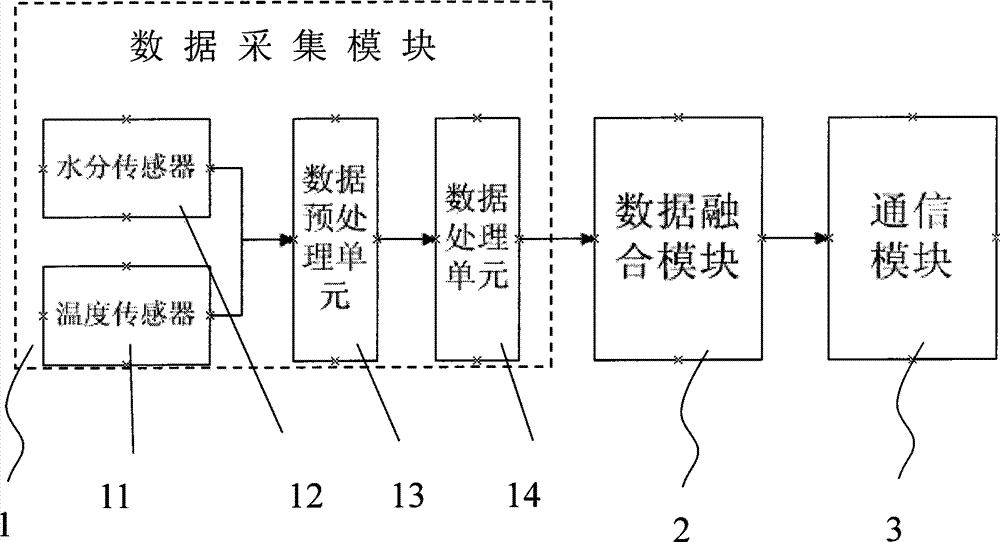

[0060] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

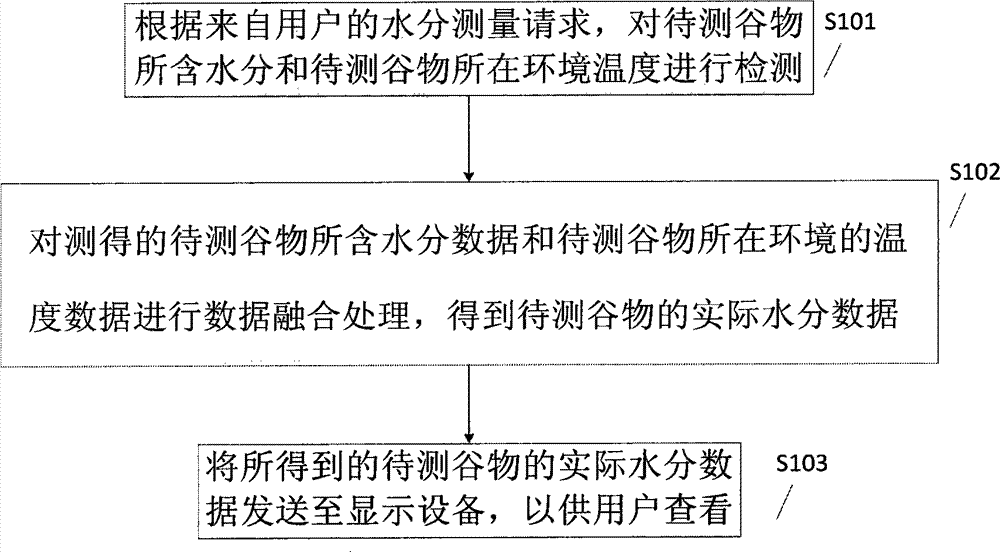

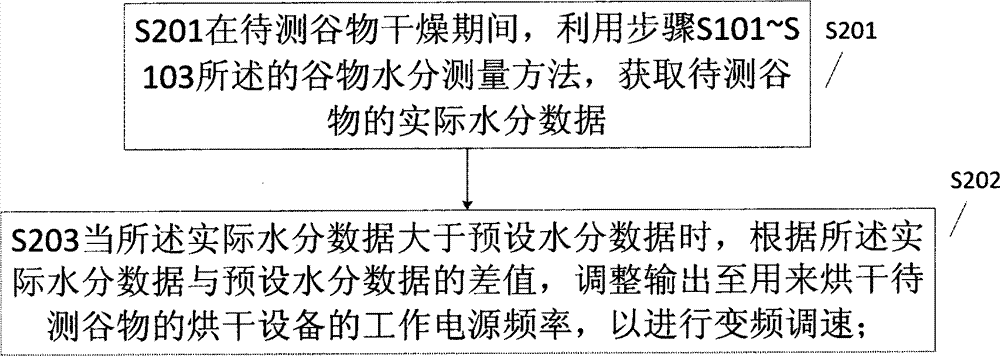

[0061] like figure 1 The flow chart of the grain moisture measuring method of the present invention shown, comprises the following steps:

[0062] S101 detects the moisture contained in the grain to be measured and the ambient temperature of the grain to be measured according to the moisture measurement request from the user;

[0063] S102 performing data fusion processing on the detected moisture data contained in the grain to be measured and the temperature data of the environment where the grain to be measured is located, to obtain actual moisture data of the grain to be measured;

[0064] S103 sends the obtained actual moisture data of the grain to be measured to the display device for viewing by the user.

[0065] Further, the detection of the moisture contained in the grain to be tested and the ambient temperature of the grain to be tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com