Closed sampling method of lithium ion battery electrolyte

A lithium-ion battery, electrolyte technology, applied in the direction of sampling devices, etc., to avoid material waste, easy to operate, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

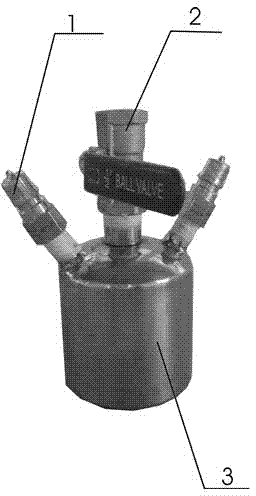

[0021] A kind of airtight sampling method of electrolyte for lithium ion battery, comprises the following steps process:

[0022] (1) Clean the airtight sampler and the airtight sampler and dry them for later use;

[0023] (2) Connect one end of the airtight sampler to the pipeline, storage tank, and packaging barrel equipment to be sampled through the corresponding quick connector, and connect the other end of the airtight sampler to the airtight sampler through the corresponding quick connector;

[0024] (3) Open the valve of the airtight sampler, and then pressurize the equipment. The electrolyte enters the airtight sampler through the quick connector and then enters the airtight sampler. During the sampling process, the airtight sampler is continuously exhausted through the quick connector until the airtight sampler filled with electrolyte;

[0025] (4) Finally close the equipment valve, close the airtight sampler valve, unplug the airtight sampler from the equipment and ...

Embodiment 2

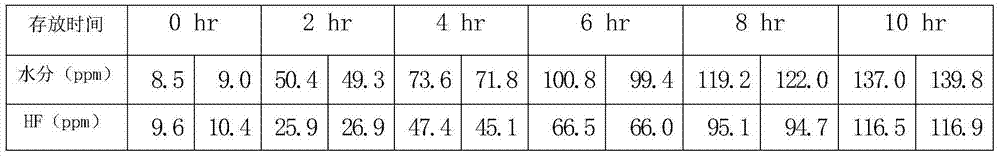

[0027] Use a 500ml PTFE beaker to take an appropriate amount of electrolyte from the electrolyte storage tank, and place it with the open mouth in an environment with a temperature of 25±0.5°C and a relative humidity of 60±2% for electrolyte storage experiments. The electrolyte moisture and free acid (calculated as HF) content were detected at different times, and the experimental data are shown in Table 1.

[0028] Table 1: Experimental data of electrolyte storage in the open

[0029]

Embodiment 3

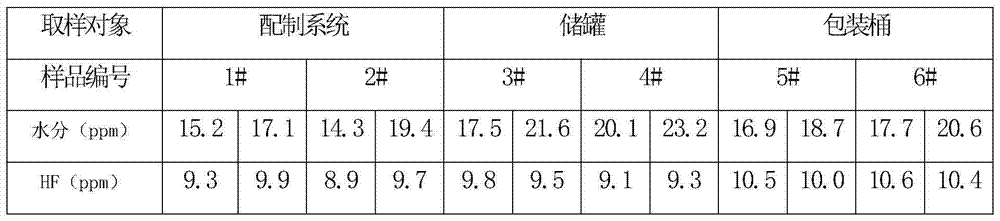

[0031] Use a conventional sampling bottle with a cover to sample twice from the electrolyte preparation system, storage tank and electrolyte packaging barrel respectively. During the sampling process, the moment the electrolyte sample flows into the sampling bottle, it contacts with the air, and the cap of the bottle is tightened after sampling. Each sample was repeatedly tested and analyzed for moisture and free acid (calculated as HF) content. See Table 2 for the experimental data.

[0032] Table 2: Experimental data of conventional sampling methods

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com