Close-link energy control method and system for main steam pressure of thermal power unit

A technology of energy-saving control system and main steam pressure, which is applied to mechanical equipment, engine components, machines/engines, etc., and can solve problems such as inability to adapt to changes in thermal power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be realized by programming on DCS (Distributed Control System, DCS), PLC (Programmable Logic Controller, PLC), single-chip microcomputer or computer. In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

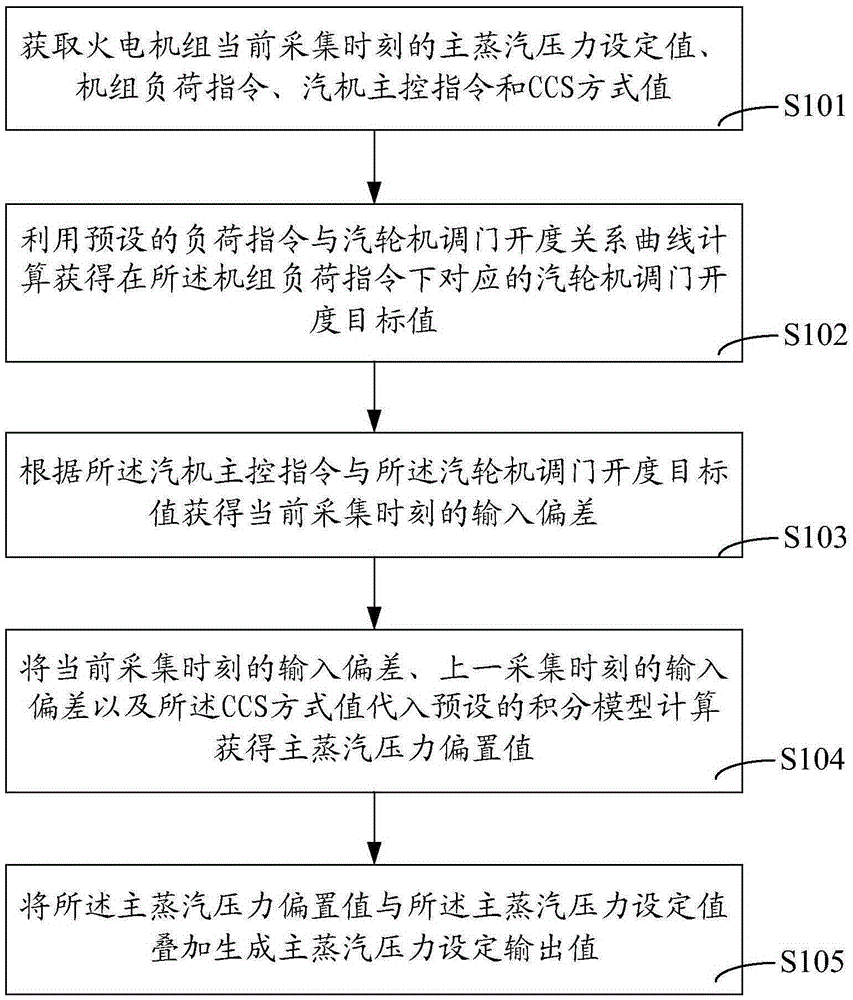

[0026] see figure 1 , which is a flow chart of an embodiment of the closed-loop energy control method for the main steam pressure of a thermal power unit according to the present invention.

[0027] A closed-link energy control method for main steam pressure of a thermal power unit, comprising the steps of:

[0028] S101: Obtain the main steam pressure setting value, unit load command, steam turbine main control command and CCS mode value at the current acquisition time of the thermal power unit;

[0029] After the collection time arrives, parameters such as the main steam pressure settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com