Method for preparing nanofiber membrane through electrostatic spinning

A nanofiber membrane and electrospinning technology, which is applied in the direction of electrospinning, fiber treatment, chemical instruments and methods, etc., can solve the problems of inability to accurately control the multi-level structure of nanometer membranes, and cannot guarantee the preparation of nanofiber membranes, so as to promote The effect of developing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

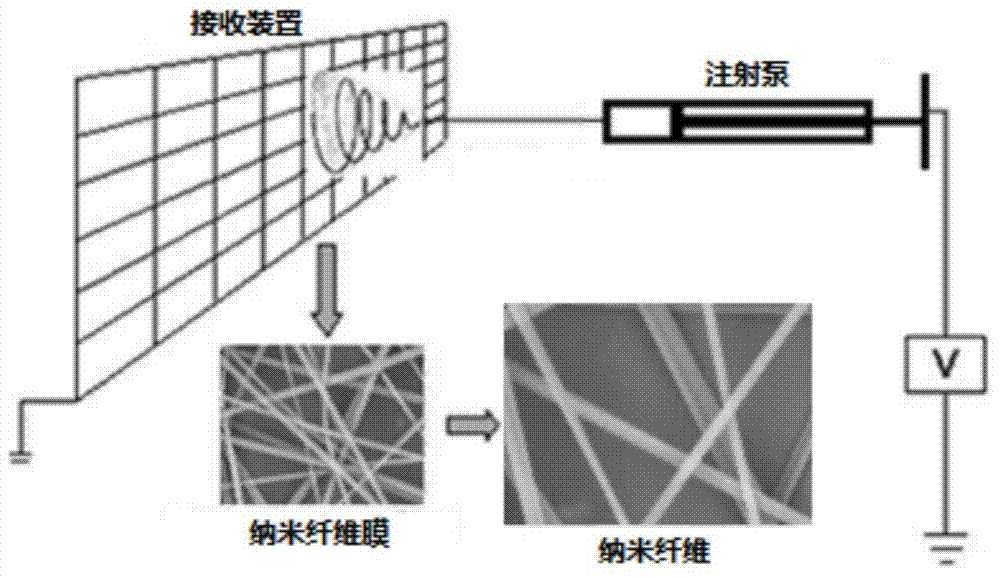

[0044] Dissolve 1.4g of polyacrylonitrile in 8.6g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 14% (g / g). Formamide spinning solution. Use a 10ml syringe and a needle with an inner diameter of 0.5mm to draw out the polyacrylonitrile / N,N-dimethylformamide spinning solution, and fix it on a micro-syringe pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 12KV, receiving distance 20cm, injection rate 0.6ml / h, ambient temperature 25°C, and ambient relative humidity 55%.

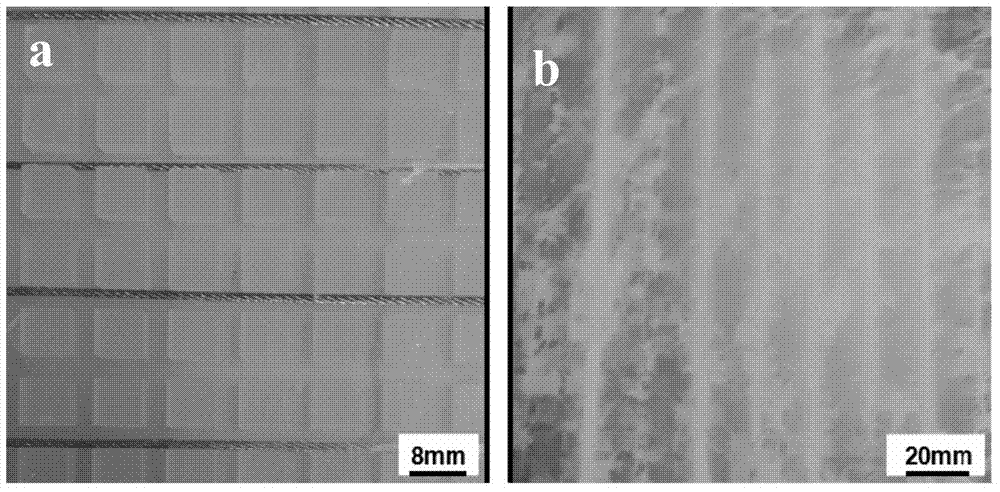

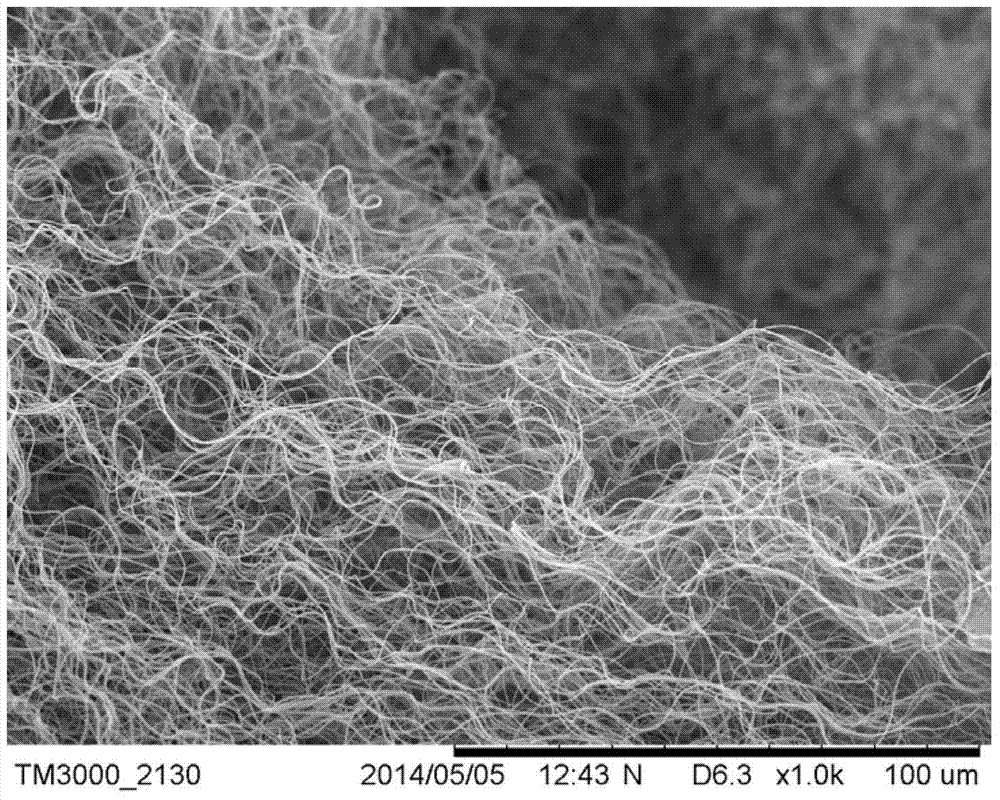

[0045] A cut plexiglass plate with a protrusion length × width × height of 8 mm × 8 mm × 8 mm, and a distance between the front and rear of the protrusions of 3 mm × 3 mm is used, and an iron wire is added in the gap as a receiving device to prepare a nanofiber film with a sparse structure. Nano-membrane with high filtration efficiency, low filtrat...

Embodiment 2

[0047] Dissolve 1.2 g of polyacrylonitrile in 8.8 g of N,N-dimethylformamide, stir for 8 hours until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 12% (g / g). Formamide spinning solution. Use a 10ml syringe and a needle with an inner diameter of 0.5mm to draw out the polyacrylonitrile / N,N-dimethylformamide spinning solution, and fix it on a micro-syringe pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 12KV, receiving distance 20cm, injection rate 0.6ml / h, ambient temperature 25°C, and ambient relative humidity 55%.

[0048] A foam packaging material thickened yarn with a raised diameter and height of 10mm×2mm and a distance between the front and back of the raised 1mm×1mm is used as a receiving device to prepare a nanofiber membrane with a sparse structure and high filtration efficiency. Nano-membrane with good filter resistance and air permeability. Ta...

Embodiment 3

[0050] Dissolve 1.4g of polyvinylidene fluoride in 8.6g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain a concentration of 14% (g / g) of polyvinylidene fluoride / N,N-dimethylformamide Methylformamide spinning solution. Use a 10ml syringe and a needle with an inner diameter of 0.5mm to draw out the polyvinylidene fluoride / N,N-dimethylformamide spinning solution, and fix it on a micro-syringe pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 12KV, receiving distance 20cm, injection rate 0.6ml / h, ambient temperature 25°C, and ambient relative humidity 55%.

[0051] A foam packaging material with a diameter and height of 10mm×2mm and a distance of 1mm×1mm between the protrusions and a fine yarn is used as the receiving device to prepare a nanofiber membrane with a sparse structure and high filtration efficiency. Nano-membrane with good filter resistance and air permeability. Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com