Novel slow-release particle magnesium fertilizer and preparation method thereof

A technology of slow-release granules and manufacturing methods, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low crop utilization rate, insoluble in water, inability to achieve multi-effect slow release, etc., and achieve long-lasting and effective crop shortage Magnesium, good fluidity, the effect of correcting magnesium deficiency in crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

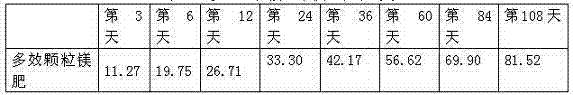

Examples

Embodiment 1

[0026] The second step is to prepare an acidic medium: take nitric acid to prepare a 1% dilute nitric acid solution, and dissolve 1 kg of water-soluble chitosan in 100 L of prepared dilute nitric acid solution to prepare a 1% water-soluble chitosan solution. Sugar acidic solution, then add 20 kg of reserved powder to the water-soluble chitosan acidic solution, and react at 30 degrees Celsius with constant temperature stirring, and the mixed solution obtained after the reaction is complete is the granulation liquid phase;

[0027] The third step, granulation: gradually add the mixed powder into the granulation tray, keep the rotation speed of 50 rpm, infiltrate with a small amount of liquid phase first, and spray the water-soluble chitosan solution while adding the powder, Carry out granulation until the particles reach the required particle size;

[0028] The fourth step, post-processing: the granulated particles are dried, cooled, and sieved to obtain a finished product: MgO3...

Embodiment 2

[0039] The second step, preparation of acidic medium: 1.8 kilograms of water-soluble chitosan is dissolved in 100L mass concentration and is 2% dilute nitric acid solution and makes water-soluble chitosan acidic solution, then in water-soluble chitosan acidic solution, then add The reserved 20 kg of uniformly mixed powder is reacted at 45 degrees Celsius with constant temperature stirring, and the mixed solution obtained after the reaction is complete is used as the granulation liquid phase;

[0040] The third step, granulation: gradually add the mixed powder into the granulation tray, keep the speed of 50 rpm, first infiltrate with a small amount of liquid phase, add the powder, and spray the water-soluble chitosan acid solution , carry out granulation until the particles reach the required particle size;

[0041] The fourth step, post-processing: the granulated particles are dried, cooled, and sieved to obtain a finished product: MgO39.63%, water-soluble chitosan0.18%, 2-4mm...

Embodiment 3

[0049] The second step, preparation of acidic medium: 0.8 kilograms of water-soluble chitosan is dissolved in 100L mass concentration and is 1% dilute nitric acid solution and makes water-soluble chitosan acidic solution, then in water-soluble chitosan acidic solution, then add The reserved 20 kg of uniformly mixed powder is reacted at 40 degrees Celsius with constant temperature stirring, and the mixed solution obtained after the reaction is complete is used as the granulation liquid phase;

[0050] The third step, granulation: gradually add the mixed powder into the granulation tray, keep the rotation speed of 50 rpm, infiltrate with a small amount of liquid phase first, and spray the water-soluble chitosan solution while adding the powder, Carry out granulation until the particles reach the required particle size;

[0051] The fourth step, post-processing: the granulated particles are dried, cooled, and sieved to obtain a finished product: MgO 29.4%, water-soluble chitosan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com