Papermaking wastewater treatment method

A treatment method and technology for papermaking wastewater, which is applied in the fields of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve problems such as difficult wastewater compliance, refractory macromolecular substances, and large loads , to achieve the effects of reduced energy consumption, improved pollutant degradation rate, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

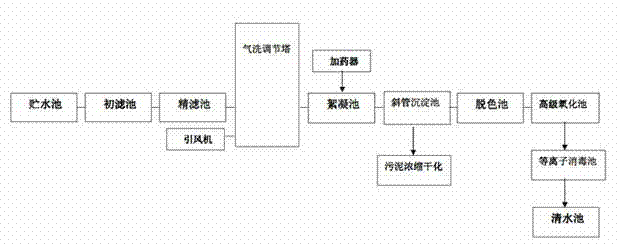

Image

Examples

Embodiment Construction

[0035] After the papermaking wastewater enters the storage tank, it will be treated in the following steps:

[0036] 1) Filtration: Use a pump to pump the wastewater in the storage tank into the primary filter, and after being filtered and separated by a 70-mesh sieve, the filtrate enters the

[0037] Fine filter, after being filtered and separated by 130 mesh sieve, the filtrate enters the air washing regulating tower;

[0038] 2) Air washing and pH adjustment: the coal-burning exhaust gas is sent from the bottom to the air washing adjustment tower by the induced draft fan, and flows from bottom to top, so that the acid gas SO in the flue gas 2 Neutralize with the alkaline substances in the wastewater to adjust and reduce the pH of the wastewater; at the same time, the soot particles in the flue gas absorb fine suspended matter such as short fibers in the wastewater to form settleable particles, which are then filtered through a filter; the filtrate enters Flocculation tank;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com