Automatic pressurization stopper pressing machine and automatic pressurization stopper pressing method

An automatic pressurization and corking machine technology, which is applied in the direction of closing plugs, transportation and packaging, and sealing with plugs, which can solve the problems of low efficiency, poor continuity of pressurization and sealing operations of medicine bottles, and unfavorable pressurized medicines. Problems such as large-scale production of bottles, to achieve the effects of improving efficiency, setting reasonable inflation time, and preventing mechanical jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

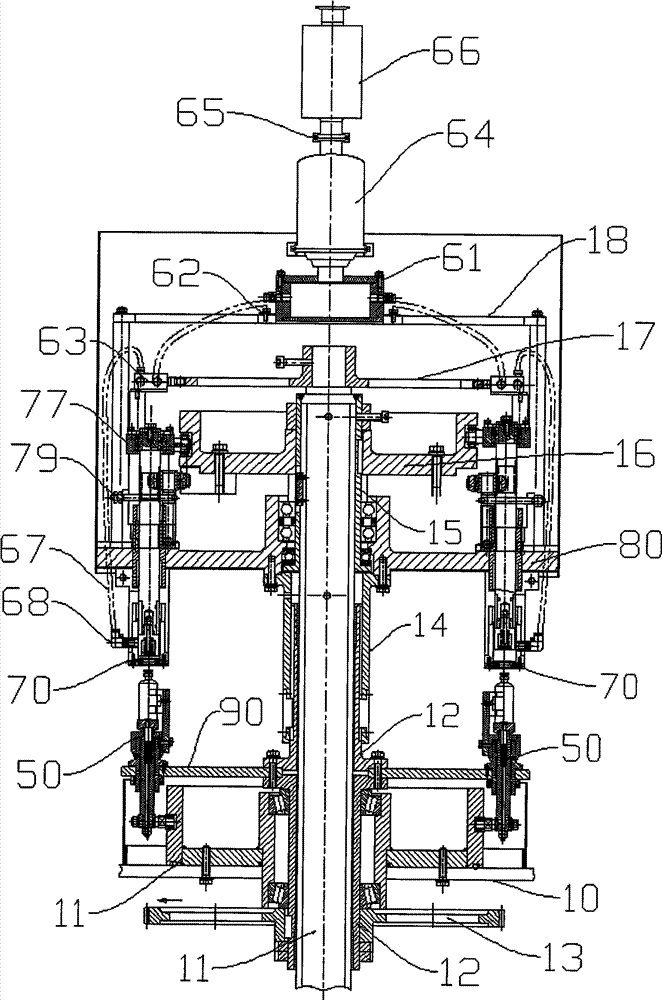

[0039] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0040] The object of the present invention is to provide an automatic pressurizing cork pressing machine, which has the advantages of simple structure, strong continuity of pressurizing and sealing operations on medicine bottles, and high working efficiency. Another object of the present invention is to provide an automatic pressurization and plugging method, which also has the advantages of high continuity and high work efficiency for pressurizing and sealing the medicine bottle.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com