Hydraulic machine for single-piece fiber cement plate pressing

A technology of fiber cement board and hydraulic press, which is applied in the field of hydraulic presses, can solve the problems of uneven plate thickness, complex process, long dehydration time, etc., and achieve the effect of reducing conveying and clutch time, reducing motor power, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows: embodiment

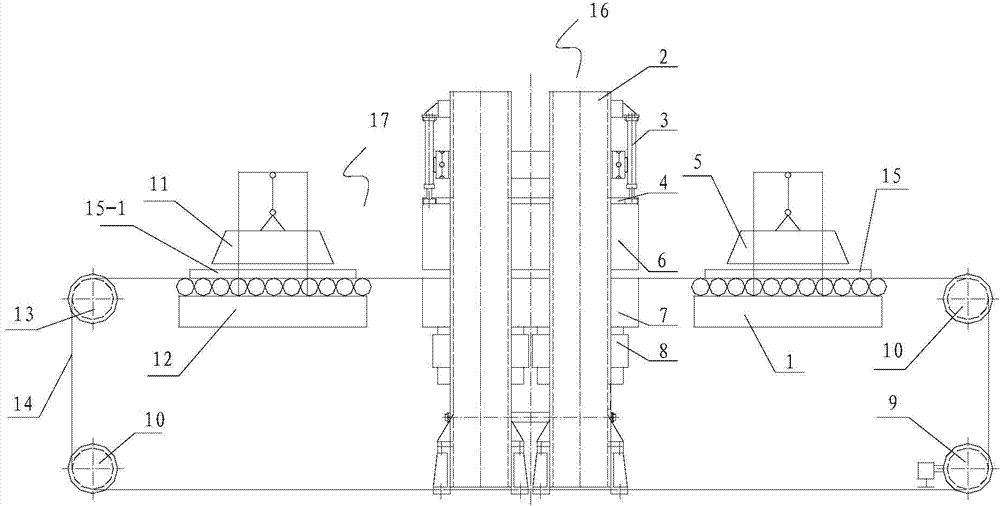

[0015] Referring to the drawings for details, this embodiment provides a hydraulic press for pressing a single piece of fiber cement board, including a hydraulic press 16 and a multi-station transfer device 17, the hydraulic press is placed in the middle of the multi-station transfer device, and the upper part of the conveyor belt passes through the slab Transfer station, pressing station and dewatered slab transfer station, the lower part of the conveyor belt passes through the bottom of the hydraulic press. The multi-station transmission device includes a conveyor belt 14, a driving drum 9, two tensioning drums 10 and a high-pressure water cleaning drum 13, and the driving drum, the tensioning drum, the high-pressure water cleaning drum and the tensioning drum arranged in sequence form a circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com