Application method of cylinder workpiece high-precision drilling fixture

A drilling jig, high-precision technology, applied in the direction of drilling dies for workpieces, manufacturing tools, metal processing machinery parts, etc. Simple structure, high machining accuracy, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

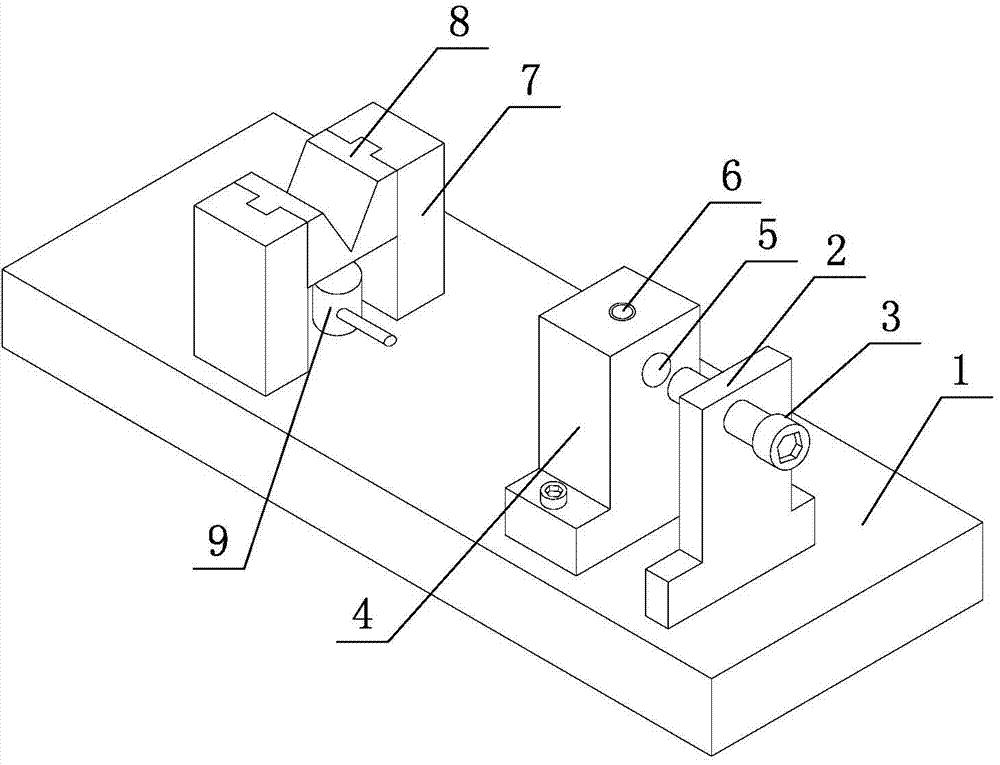

[0013] Such as figure 1 As shown, the present invention includes a base plate 1; a pair of adjustment seats 7, a drill base 4 and a support seat 2 are fixedly connected to the base plate 1 from left to right; V-shaped support block 8, the support block 8 can slide up and down along the chute, the bottom plate 1 is positioned at the bottom of the V-shaped support block 8 and a jack 9 is installed, adjusting the jack 9 can adjust the vertical height of the support block 8, and then to The workpiece on the V-shaped support block 8 is adjusted vertically; the drill base 4 has a horizontal positioning hole 5 and a vertical drilling mold 6. Die 6 punches the workpiece; the support seat 2 is vertically fixed to the screw 3, and the end of the screw 3 is facing the positioning hole 5, which can limit the workpiece. At the same time, the screw 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com