A kind of preparation method of stainless steel clad plate

A clad plate and stainless steel technology, applied in the field of stainless steel clad plate preparation, can solve problems such as poor use effect and difficult connection, and achieve the effects of avoiding large welding workload, accelerating strain and improving outer surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

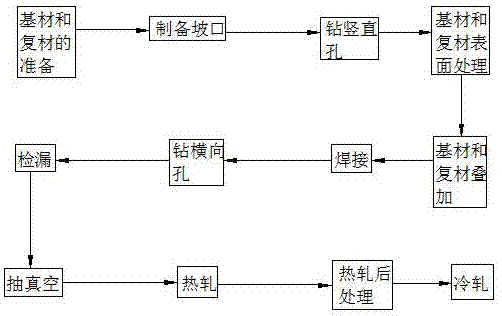

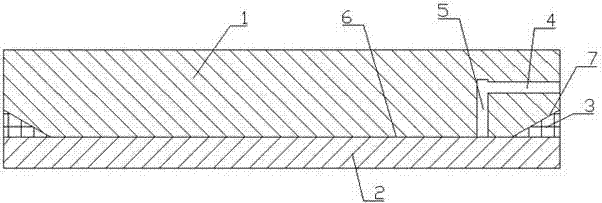

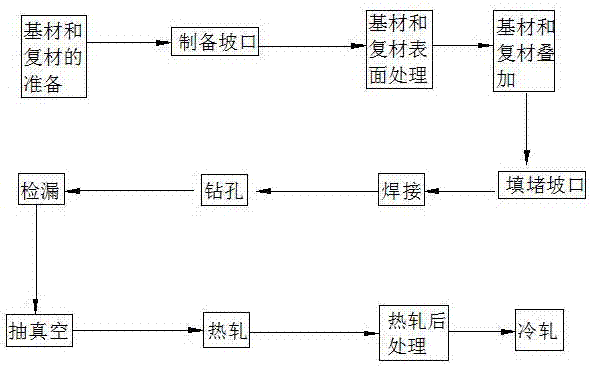

[0057] Example 1, such as figure 1 and figure 2The preparation method of a kind of stainless steel clad plate shown, comprises the following steps in turn:

[0058] 1. For the preparation of base material and composite material, 201 stainless steel is selected as base material 1, and 304 stainless steel is used as composite material 2. Because the cost of 304 stainless steel is higher than that of 201 stainless steel, in order to reduce costs and ensure the performance of the finished product, base material 1 And the thickness ratio of the composite material 2 is 8.5:1.5; after selecting the base material 1 and the composite material 2, use a plasma cutting machine to cut the base material 1 and the composite material 2 so that the length and width of the two are the same; thus making The two edges are flush during the superimposition process.

[0059] 2. Prepare the groove, choose one of the upper and lower surfaces of the substrate 1 as the first surface 6, and make groov...

Embodiment 2

[0072] Example 2, in step 1, in the preparation of base material 1 and composite material 2, the thickness ratio of base material 1 and composite material 2 is 8.7:1.3; in step 2, during the preparation of groove 7, the length of the formed slope surface is 23mm, and the inclination angle is 35°; step 4, drilling the vertical hole, the depth of the vertical hole 5 is 0.55 of the thickness of the base material 1; the distance between the vertical hole 5 and the groove is 11mm; step 6, welding , the current is 300A during rooting welding; when the groove 7 is fully welded to form the weld meat 3 by automatic submerged arc welding, the current of 300A is used for a period of time, and then the current of 600A is used; step 8, leak detection, to The pressure of the inert gas connected to the steel pipe is 1Mpa; step 9, during vacuuming, the pressure in the composite billet is 4Pa during the vacuuming process, and the pressure value can be maintained for 15 minutes, and there is no ...

Embodiment 3

[0073] Example 3, in step 1, in the preparation of base material 1 and composite material 2, the thickness ratio of base material 1 and composite material 2 is 9:1; in step 2, during the preparation of the groove, the length of the formed slope is 25mm, the inclination angle is 40°; step 4, drilling the vertical hole, the depth of the vertical hole 5 is 2 / 3 of the base material thickness; the distance between the vertical hole 5 and the groove is 12mm; step 6, welding , the current is 400A for bottom welding; when automatic submerged arc welding is used to weld the groove to form weld meat 3, first use a current of 300A for a period of time, and then use a current of 700A; step 8, leak detection, to the steel pipe The pressure of the inert gas inserted in the process is 2Mpa; Step 9, during vacuuming, the pressure in the composite billet is 5Pa during the vacuuming process, and the pressure value can be maintained for 10 minutes, when there is no pressure rebound Indicates tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com