Cream and milk fat product flavoured by two-enzyme method and preparation method thereof

A dairy product, double-enzyme technology, applied in dairy products, other dairy products, applications, etc., can solve the problem of unsatisfactory flavor of lipase hydrolyzed cream and milk, and achieve strong emulsifying properties and improve the effect of taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Lipase Piccantase A and phospholipase Maxapal A2: DSM (China) Co., Ltd.

[0064] Cream: Commercially available butter is mixed with water, homogenized by a homogenizer under a pressure of 200bar, and the fat content is 35%.

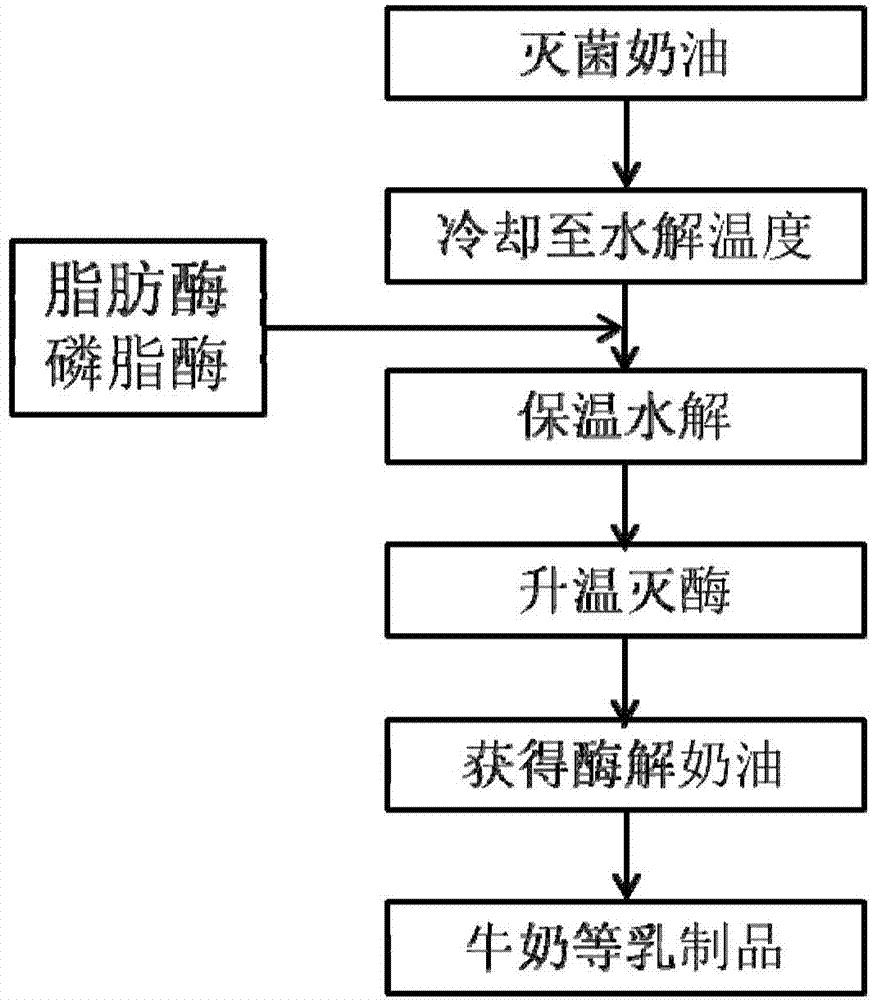

[0065] The process steps are as follows:

[0066] 1) Cream sterilization: the fat content is 35%, the sterilization temperature is 95°C, the sterilization time is 5min, and the temperature is lowered to 30°C.

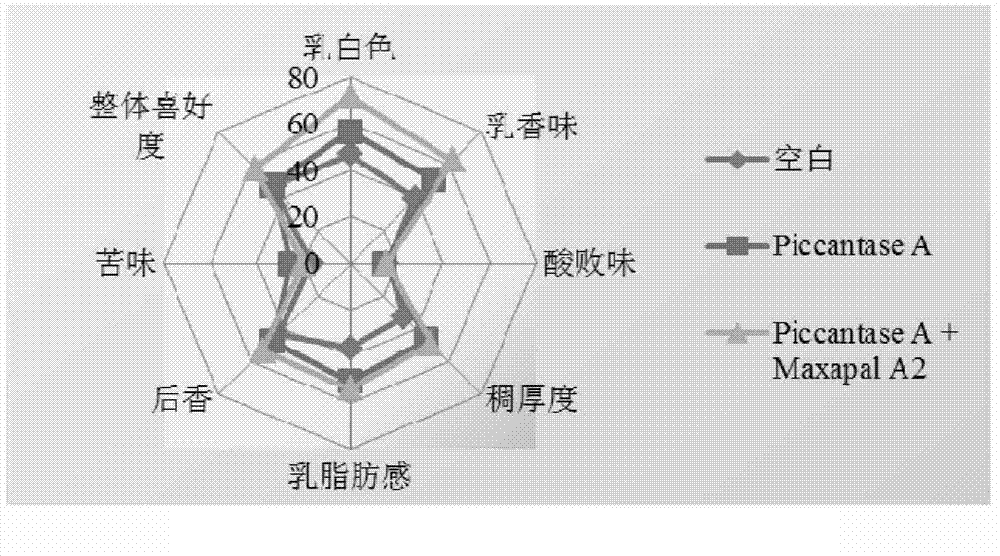

[0067] 2) Dilute the lipase 5 times with deionized water and add it to the cream together with the phospholipase, wherein the amount of the lipase Piccantase A is 1% of the cream, and the amount of the phospholipase Maxapal A2 is 0.5% of the cream. In order to better analyze the reasons for the differences in the effects of different lipases, the role of phospholipase A2. The specific scheme design is shown in Table 1.

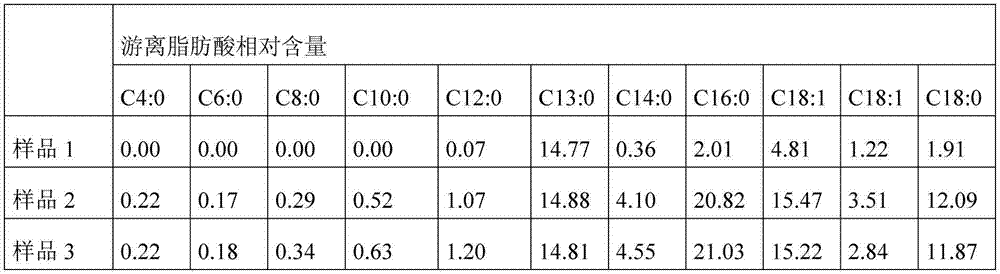

[0068] Table 1 Test plan for the effect of different enzyme hydrolyzed butter on free fatty acids

[0069] ...

Embodiment 2

[0080] Lipase Piccantase A and phospholipase Maxapal A2: DSM (China) Co., Ltd.

[0081] Cream: Commercially available butter is mixed with water, homogenized by a homogenizer under a pressure of 200bar, and the fat content is 35%.

[0082] The process steps are as follows:

[0083] 1) Cream sterilization: the fat content is 35%, the sterilization temperature is 95°C, the sterilization time is 5min, and the temperature is lowered to 30°C.

[0084] 2) Dilute the lipase 5 times with deionized water and add it to the cream together with the phospholipase, wherein the amount of the lipase Piccantase A is 1% of the cream, and the amount of the phospholipase Maxapal A2 is 0.5% of the cream.

[0085] 3) Enzymolysis: Stir for about 1 hour at 30°C, and the pH at the end point is 5.40.

[0086] 4) Enzyme inactivation: heat up the above-mentioned enzymolyzed cream to 95° C., keep it warm for 5 minutes, and inactivate the enzyme.

[0087] 5) The lipolysis product is mixed with the pretr...

Embodiment 3

[0091] Lipase Piccantase A and phospholipase Maxapal A2: DSM (China) Co., Ltd.

[0092] Cream: Commercially available butter is mixed with water, homogenized by a homogenizer under a pressure of 200bar, and the fat content is 35%.

[0093] The process steps are as follows:

[0094] 1) Cream sterilization: the fat content is 35%, the sterilization temperature is 95°C, the sterilization time is 5min, and the temperature is lowered to 30°C.

[0095] 2) Dilute the lipase 5 times with deionized water and add it to the cream together with the phospholipase, wherein the amount of the lipase Piccantase A is 1% of the cream, and the amount of the phospholipase Maxapal A2 is 0.5% of the cream.

[0096] 3) Enzymolysis: Stir for about 1 hour at 30°C, and the pH at the end point is 5.40.

[0097] 4) Enzyme inactivation: heat up the above-mentioned enzymolyzed cream to 95° C., keep it warm for 5 minutes, and inactivate the enzyme.

[0098] 5) The enzymatic lipolysis product is mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com