Fully-automatic molten steel temperature measurement and sampling device

A sampling device, fully automatic technology, applied in the direction of sampling device, measuring device, thermometer, etc., can solve the problems of low efficiency, easy to be dangerous, poor working environment, etc., achieve coherent and fast operation process, save operation time, and avoid manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

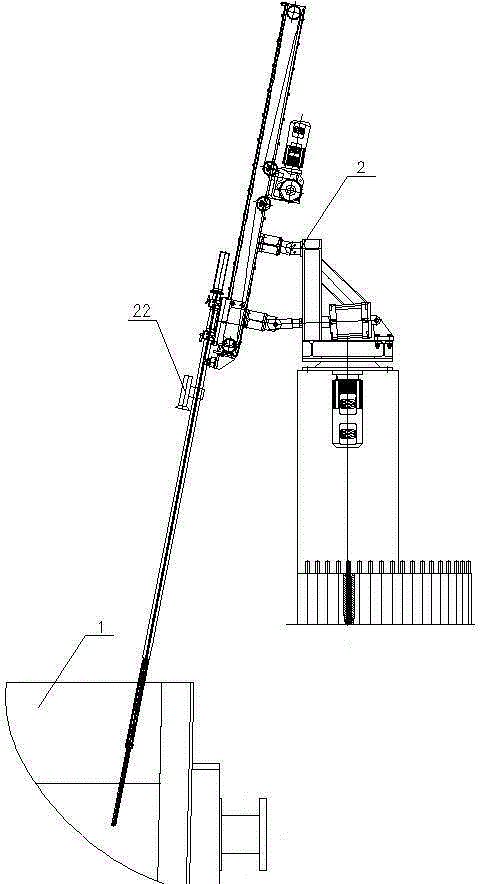

[0025] Such as figure 1 As shown, the automatic temperature measurement and sampling device 2 is set on the platform support on one side of the ladle 1. During operation, the gun body 4 tilts and extends out of the gun head 19 equipped with a probe, and the probe is inserted into the molten steel for temperature measurement and sampling.

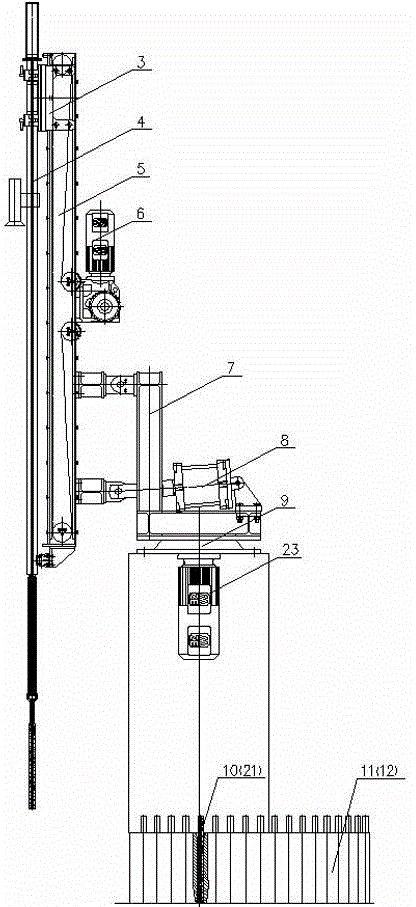

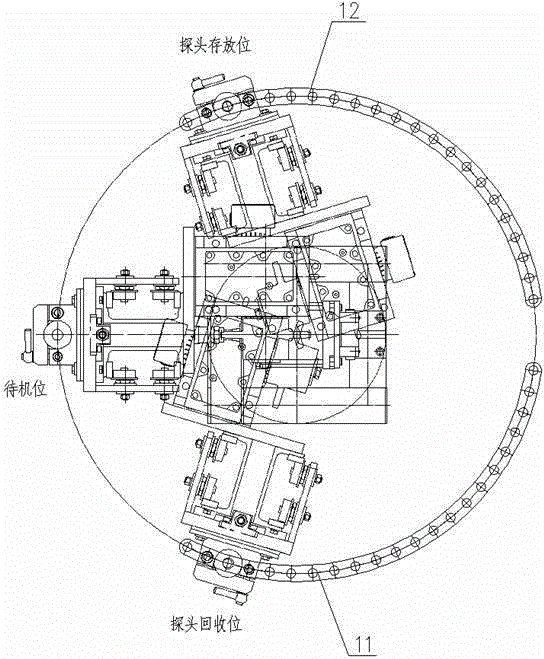

[0026] Such as figure 2 and image 3 As shown, the fully automatic molten steel temperature measurement and sampling device includes a rotating base 9, a gun frame 5, a trolley 3, a gun body 4, a first motor 6, a second motor 23, a laser range finder 22, a storage bin 12, a recycling Warehouse 11 and console; said dolly 3 is located on the gun rack 5 and cooperates with the guide rail on the gun rack 5, and the first motor 6 is connected with the dolly 3 through a transmission mechanism (the first motor 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com