Membrane stripping device, membrane stripping method and one-stop tooth socket production system

A technology of stripping and braces, applied in the field of medical devices, can solve problems such as changes in dental health, changes in tooth arrangement again, and large production space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present application will be further described in detail through the following examples, the purpose of which is to better understand the content of the present application rather than limit the protection scope of the present application.

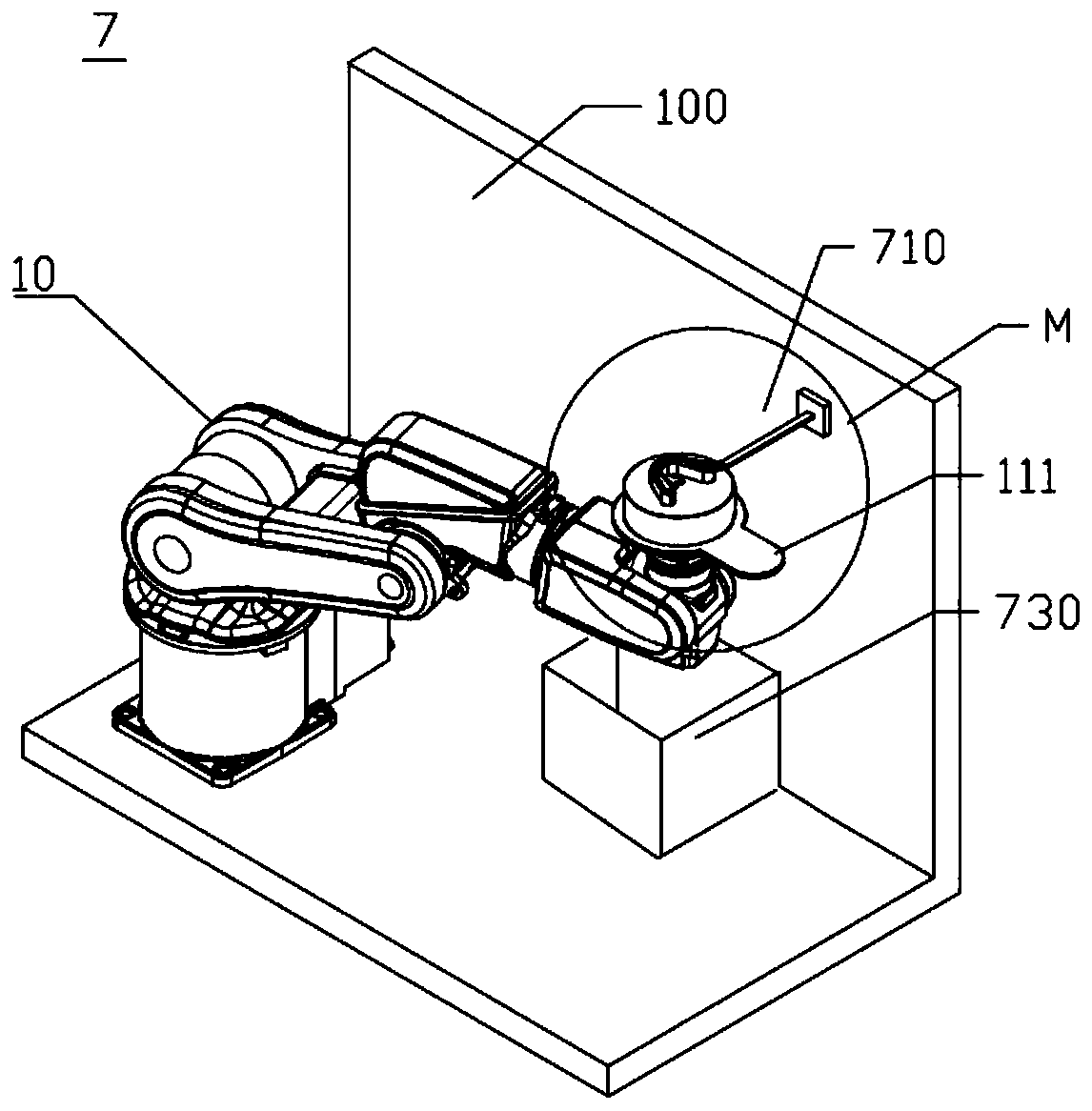

[0077] Such as figure 1 As shown, the one-stop braces production system of the present invention includes a control device 1, a jaw model preparation device 11, a laminating device 5, a cutting device 6, a stripping device 7, an automatic transfer device 10, a braces cleaning device 8 and a braces distribution unit. Picking and packaging device 9; the jaw model preparation device 11 includes a dental model printing device 2, a dental model cleaning and drying device 3, and a dental model curing device 4. In this embodiment, the above-mentioned equipment or devices share the control device 1 . Of course, the number of control devices is not the core of the present invention, and feasible solutions can be used instead. The control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com