MOCVD equipment real-time temperature measurement system self-calibration method

A self-calibration and equipment technology, which is applied in the field of self-calibration of MOCVD equipment real-time temperature measurement system, can solve the problems of temperature deviation, epitaxial wafer growth temperature measurement cannot be consistent and accurate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

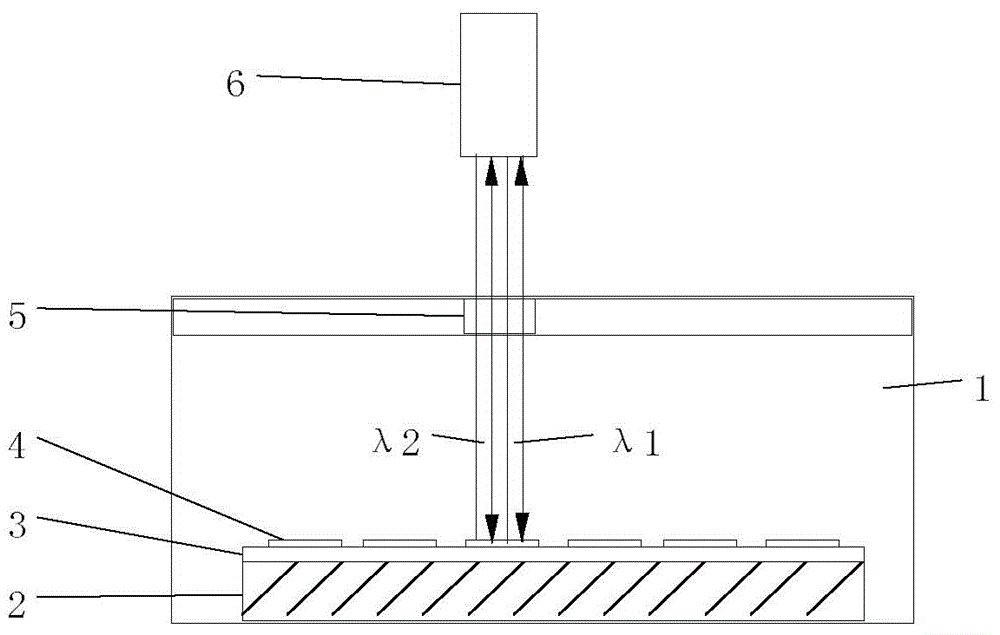

[0054] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

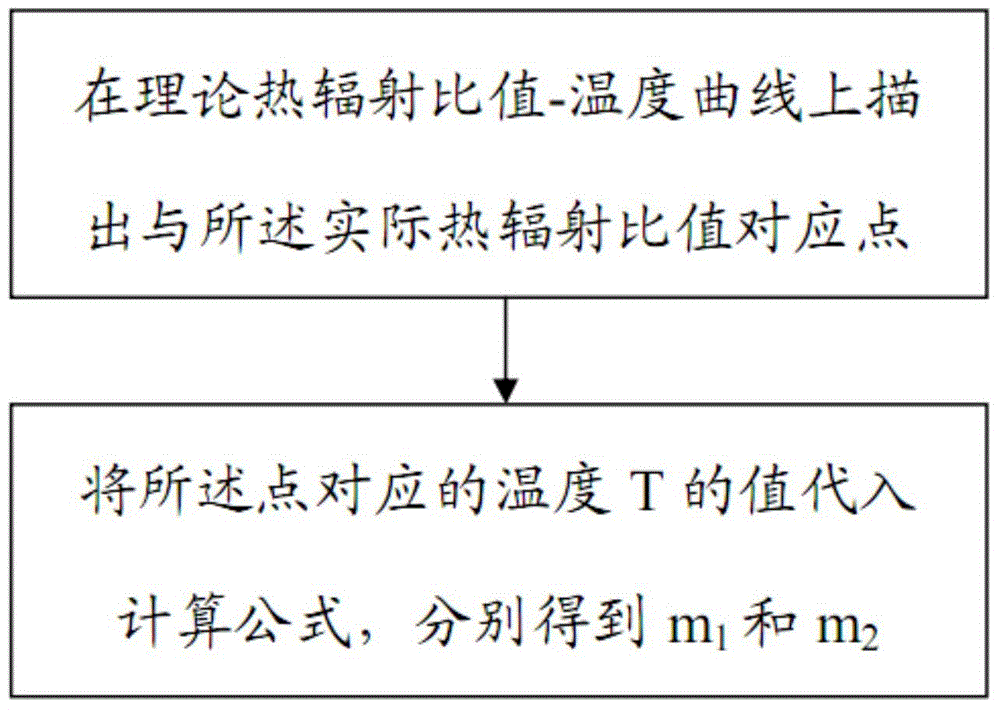

[0055] See attached figure 2 , the MOCVD equipment real-time temperature measurement system self-calibration method provided by the present invention comprises the following steps:

[0056] Step 1: According to the actual heat radiation ratio, in the attached figure 1 The points corresponding to the actual thermal radiation ratio are traced on the theoretical thermal radiation ratio-temperature curve shown;

[0057] Step 2: Substitute the value of temperature T corresponding to the point into

[0058] L ( λ 1 , T ) = m 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com