Measurement method for circular cooler orbits

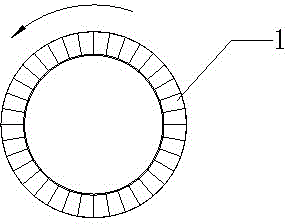

A measurement method and technology of annular coolers, which are applied in the processing of discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of re-gnawing rails, affecting production, rail roundness, and large elevation errors, avoiding the The effect of car gnawing on rails, reasonable design, and reduction of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

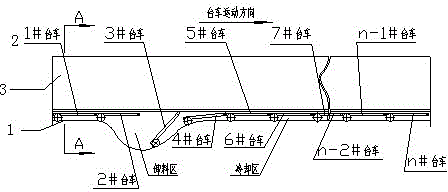

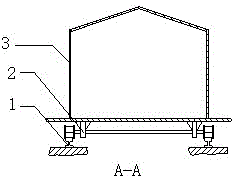

[0043] The measuring method of annular cooler track of the present invention comprises the following steps:

[0044] see now Figure 5 , Figure 5 It is a schematic diagram of opening a square hole on a rotating frame wall plate according to an embodiment of the present invention.

[0045] a. Open a square hole 8 with a side length of 100mm on the inner and outer wall plates of the rotating frame by gas cutting, and make the square holes on the inner and outer wall plates in a radial direction and have the same height;

[0046] b. Set the first measurement point 10, which is the running direction of the trolley, the end of the curved track, and the first point of the first horizontal rail. Install a total station at the center of the ring cooler to determine the position of the points to be measured. Image 6 It is a schematic diagram of the installation position of the total station according to the embodiment of the present invention.

[0047] c. Start the ring cooler wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com