Deepwater subsea pipeline starting laying method

A submarine pipeline and deep-water technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of pipeline torsion, complicated head, difficult to control installation, etc., and achieve the effect of solving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

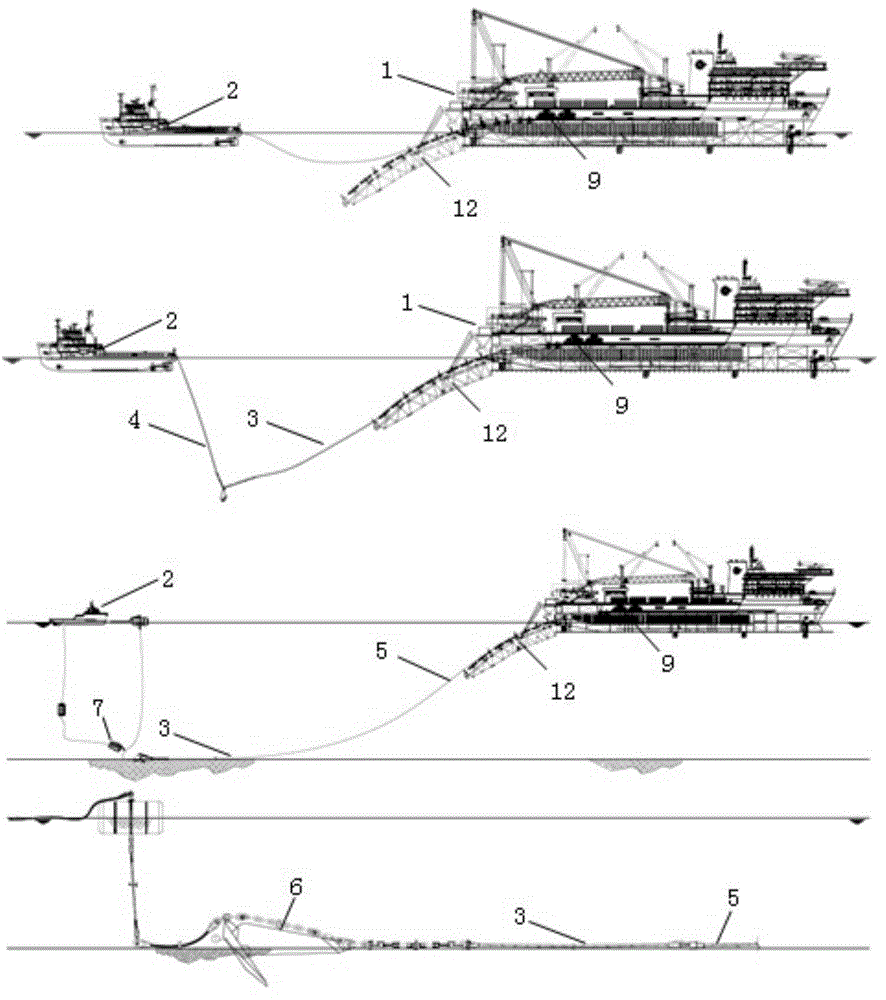

[0033] Such as figure 1 — image 3 Shown, the present invention adopts following steps:

[0034] The first step is to drive the main workboat 1 to the work site and put it in place, then connect the main workboat 1 with the anchored tugboat 2 through the traction wire, and the tugboat 2 will pull the coiled starting cable 3 and the main workboat 1 The steel wire is connected, and the starting cable 3 of the tugboat 2 is pulled to the stern of the main operation ship 1 by the traction steel wire; the abandoned pipe recovery cable 5 is connected with the starting cable 3 by the main operation ship 1;

[0035] In the second step, the tugboat 2 is sailed to the stern of the main workboat 1, and the starting cable 3 is released, the tugboat 2 sails to the target anchor point, and the starting anchor 6 is thrown to the target point area by the anchor cable 4 on the tugboat drum.

[0036] The third step, such as figure 2 As shown, the main workboat 1 pulls the starting cable 3 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com