Shock absorber

一种减震器、保持器的技术,应用在减震器、减振器、弹簧/减震器等方向,能够解决改善乘坐舒适感限制、不能可变地控制阻尼力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

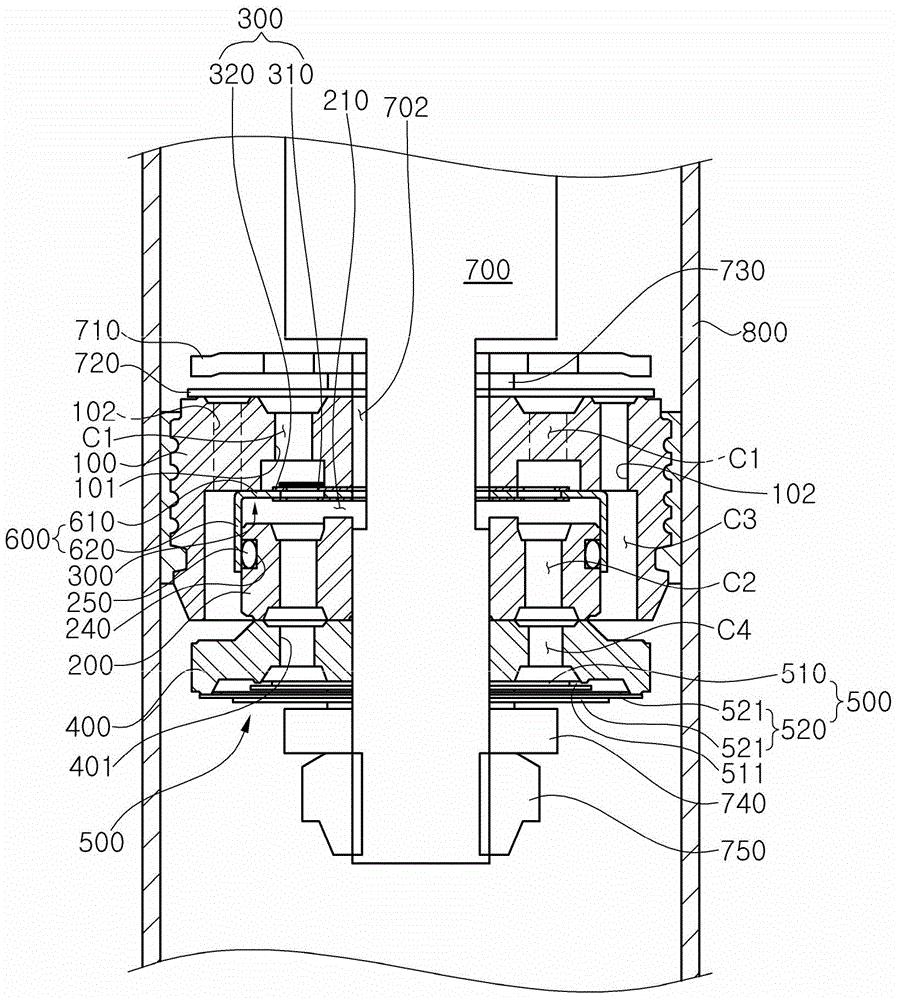

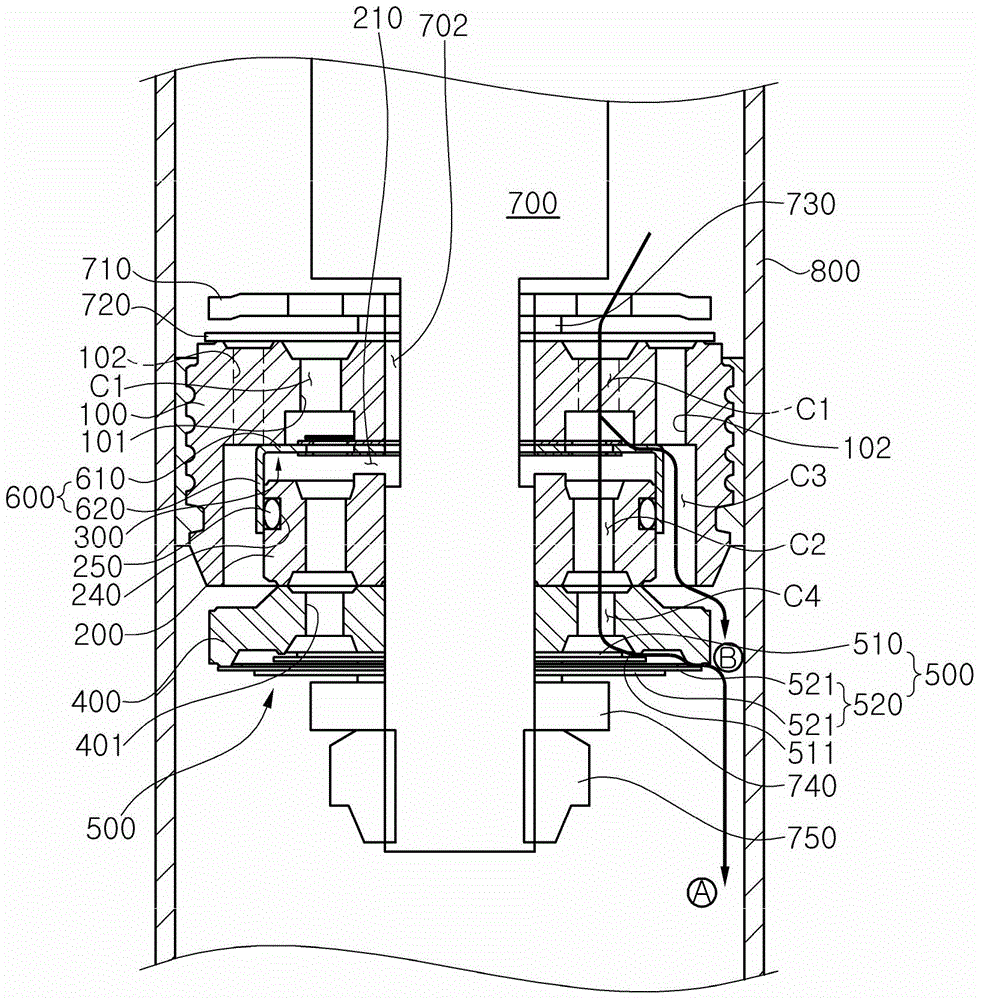

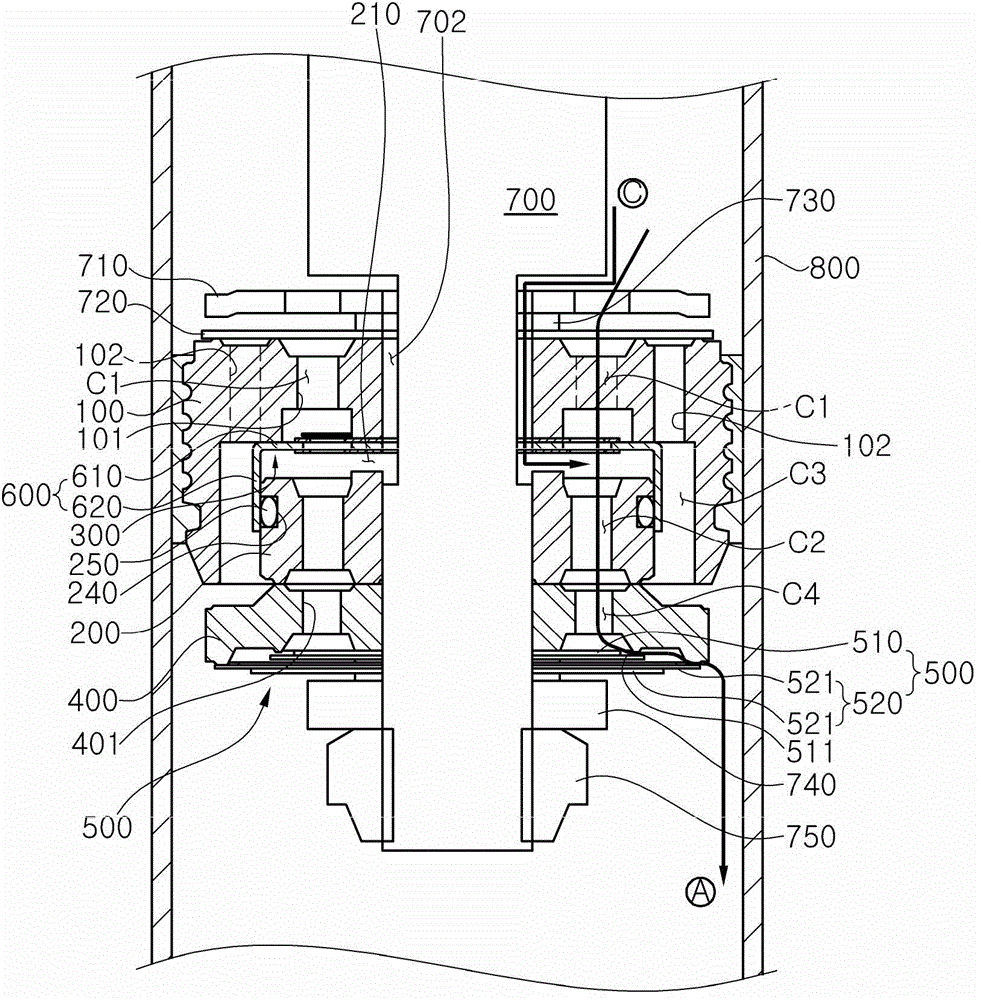

[0021] Hereinafter, a shock absorber according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

[0022] figure 1 is a schematic cross-sectional conceptual diagram illustrating the overall structure of a shock absorber according to an embodiment of the present invention, figure 2 is a cross-sectional conceptual schematic diagram illustrating the flow of a working fluid in a high-frequency mode (small-amplitude mode) during a rebound stroke in a shock absorber according to an embodiment of the present invention, and image 3 is a cross-sectional conceptual schematic diagram illustrating the flow of a working fluid in a low-frequency mode (large-amplitude mode) during a rebound stroke in a shock absorber according to an embodiment of the present invention.

[0023] refer to Figure 1-3 , The shock absorber according to a preferred embodiment of the present invention includes a piston rod 700 , a first piston 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com