Method and device for treating iron-containing waste sulfuric acid

A technology of treatment device and treatment method, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve problems such as difficulty in removal, and achieve the effects of economical and efficient treatment, high practicability, and high sulfuric acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

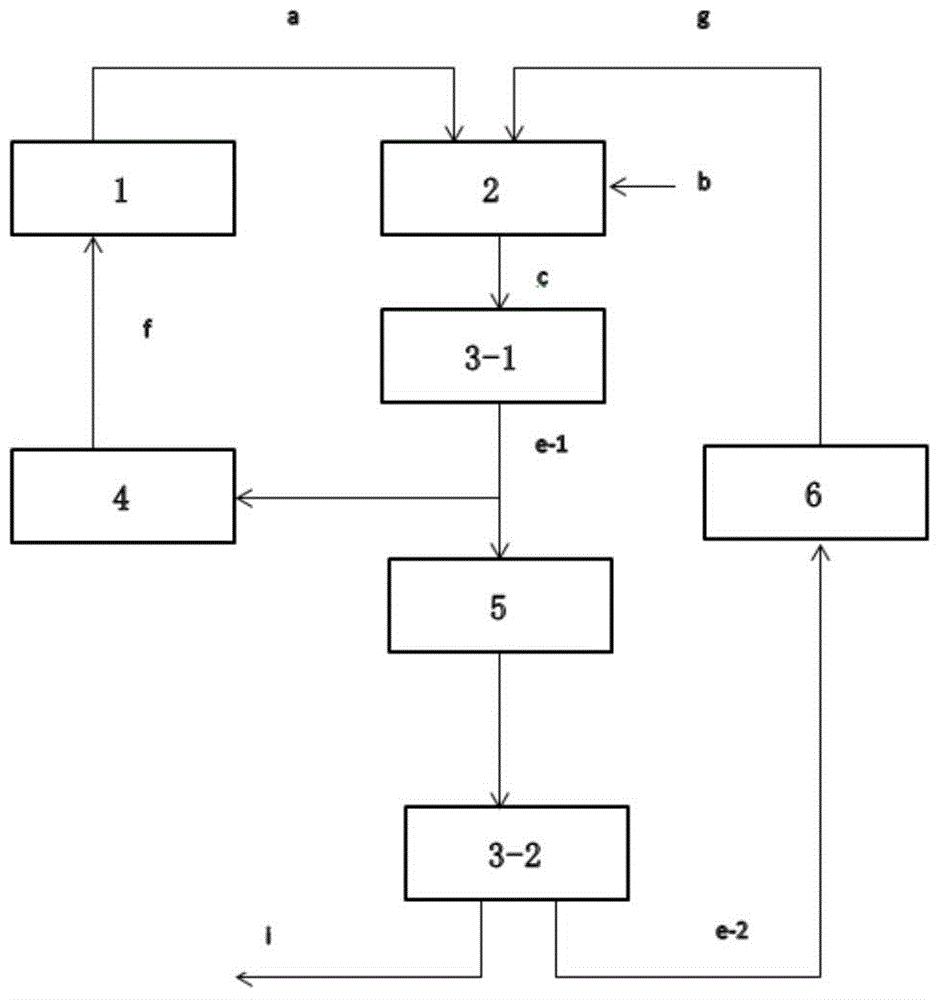

[0041] use figure 2 The device is processed, and the iron-containing waste sulfuric acid a (concentration of sulfuric acid: 10wt%, ferrous sulfate content: 15wt%) 10kg that pickling unit 1 generates is transported in the mixing device 2, adds the regenerated concentrated sulfuric acid g10kg of 80wt% concentration (sulfuric acid Ferrous content: 0.8wt%) and 98wt% concentrated sulfuric acid b1kg, mixed and stirred to separate out ferrous sulfate crystals. First, the first separation device 3-1 sets the solid-liquid mixture c into solid-liquid separation to obtain 1.68kg of ferrous sulfate crystal d (ferrous sulfate monohydrate), 19.3kg of liquid e-1 (concentration of sulfuric acid: 52wt%, sulfuric acid Ferrous concentration: 0.5wt%) recovery.

[0042] Next the liquid e-13.3kg that reclaims enters dilution device 4 and is diluted and obtains regenerated dilute sulfuric acid f for the surface treatment of steel, and all the other liquid e-116kg (concentration of sulfuric acid: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com