Underwater adaptive mooring cable tension device

A tensioning device and self-adaptive technology, used in transportation and packaging, special-purpose ships, ships, etc., can solve the problems of mooring slack, mooring stuck, hidden dangers of normal operation of underwater winches, etc., to eliminate lateral effects power, reducing power and power consumption, improving environmental adaptability and the ability to withstand harsh sea conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

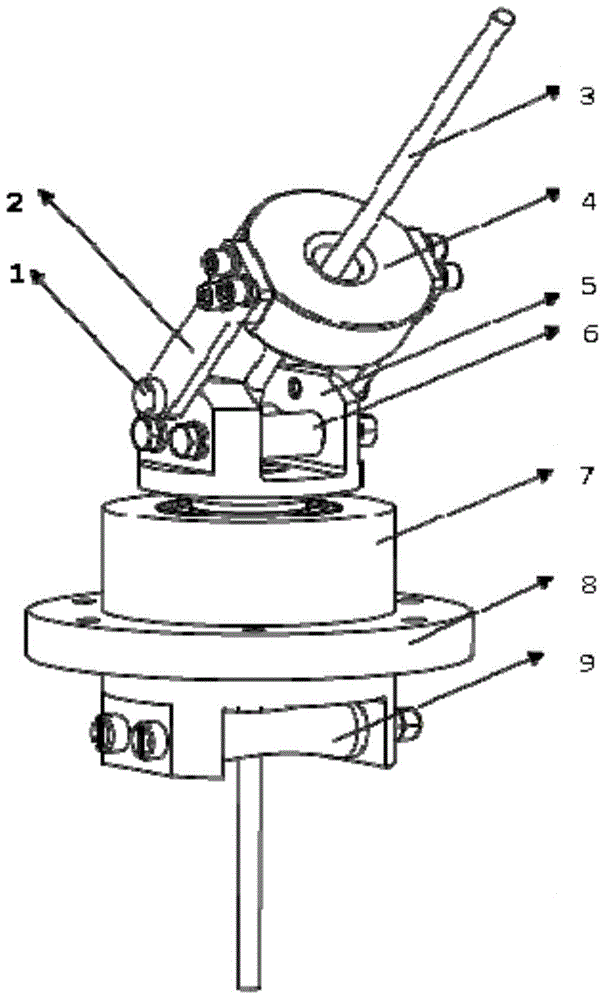

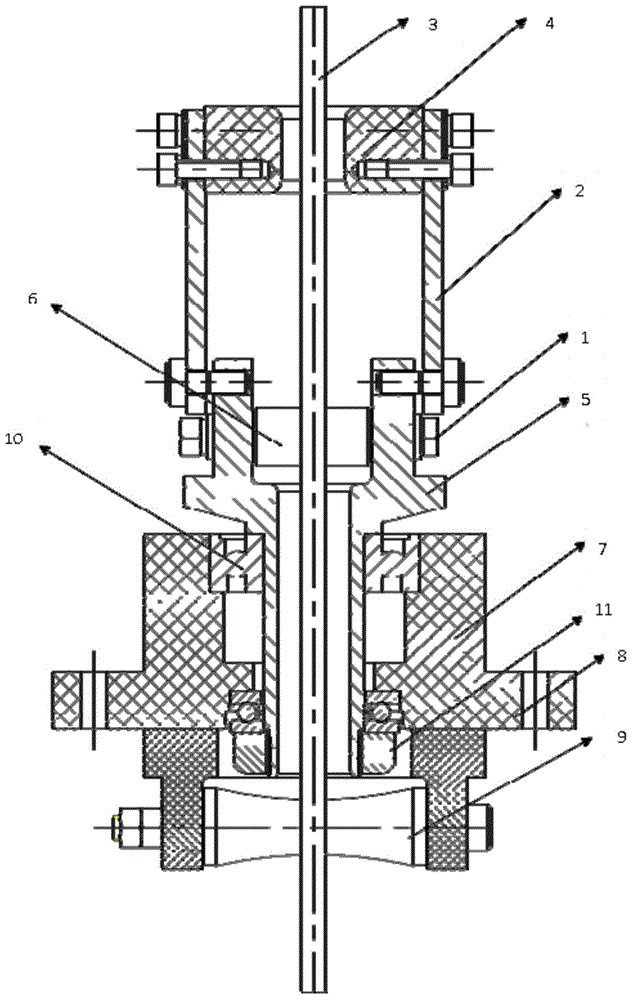

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] figure 1 and figure 2 The basic structure of the underwater self-adaptive mooring cable tensioning device involved in the present invention is shown. 7 and the tension roller group, the rotating base 5 is installed on the base 7, the thrust bearing 10 and the radial bearing 11 connect the rotating base 5 and the base 7 together, and the cable entrance 4 is connected to the rotating base 5 through the hinged support arm 2 Above, the tensioning roller group is arranged in the rotating seat 5 and the base 7, and the tensioning roller group clamps the mooring cable 3 entering and passing through the rotating seat 5 and the base 7 from the entrance and exit cable port 4.

[0026] The lower part of the rotating seat 5 is cylindrical, and the upper part is concave. The bottom of the rotating base 5 is inserted into the base 7, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com