Multifunctional curing box for mass concrete

A large-volume concrete and curing box technology, applied in the field of concrete curing boxes, can solve problems such as lack of theoretical basis, achieve reasonable layout, reduce temperature cracks, and enhance durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

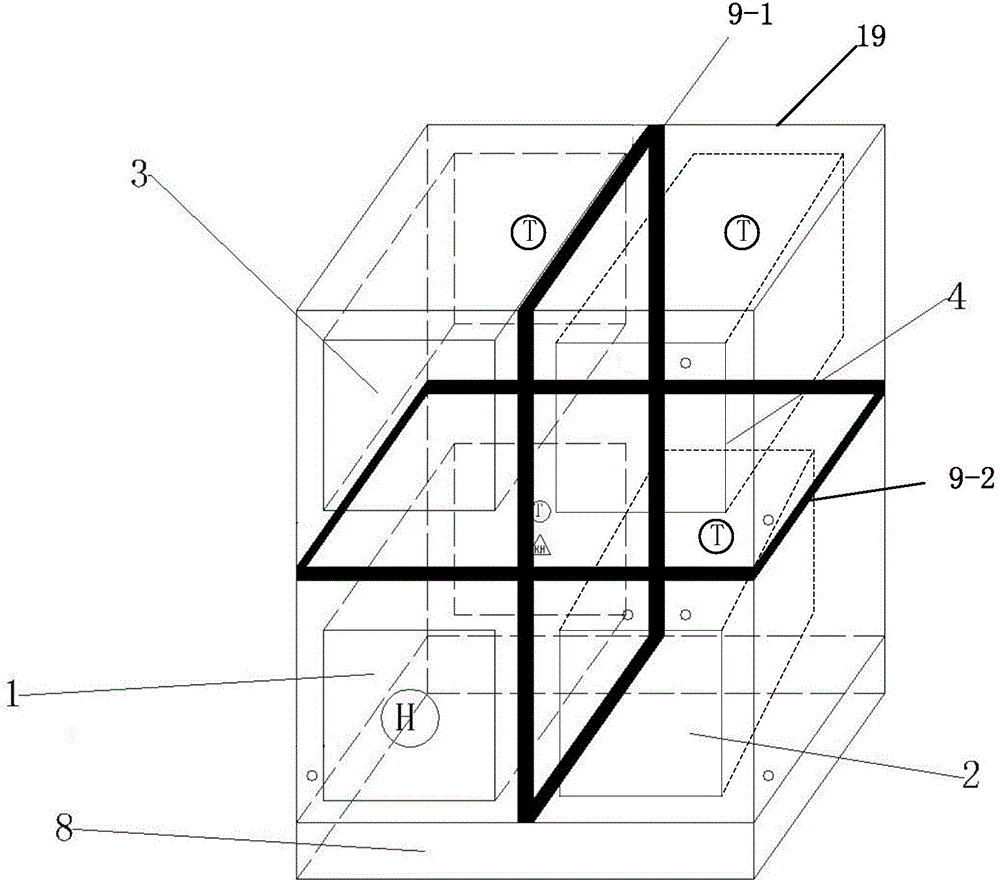

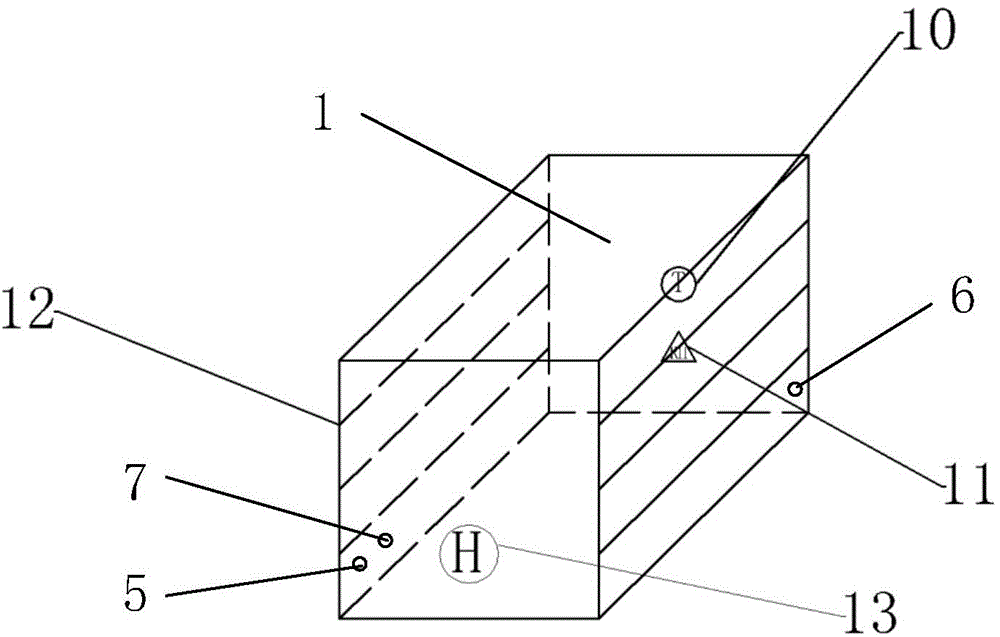

[0016] combine Figure 1 to Figure 3 , the present invention comprises a box body 19 with a door, four cavities formed by a horizontal thermal insulation and water-proof layer 9-2 vertically installed inside the box body with a door 19 and a vertical thermal insulation and water-proof layer 9-1 and installed in the With the cooling and heating device 8 at the bottom of the box body 19 with a door, a standard curing box 1 is set in the first cavity, and the standard curing box 1 is such as figure 2 As shown; in the second chamber, a curing box 2 with a maximum temperature of 30° is set, in the third cavity is set a curing box 3 with a maximum temperature of 60°, in the fourth cavity, a curing box 4 with a maximum temperature of 80° is set, standard The curing box 1, the curing box 2 with a maximum temperature of 30°, the curing box 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com