Forming method of cement decorative board with pre-embedded pendants

A molding method and decorative panel technology, applied in the direction of ceramic molding machines, molding conveyors, manufacturing tools, etc., can solve the problems of complex and difficult mechanized molding, and achieve high production efficiency, rich exterior walls and facades, and beautify the city Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

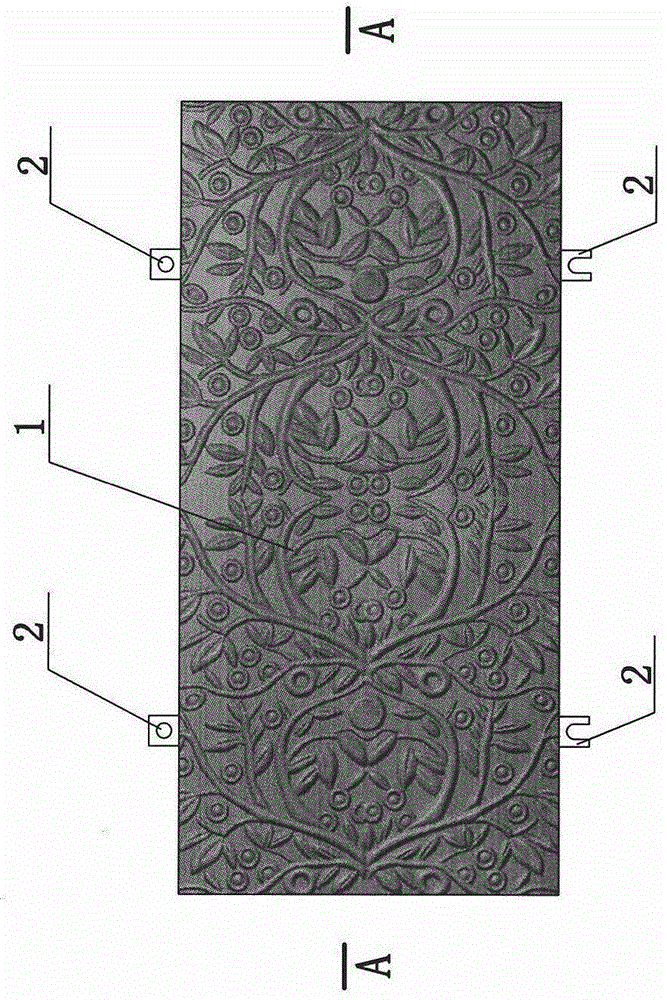

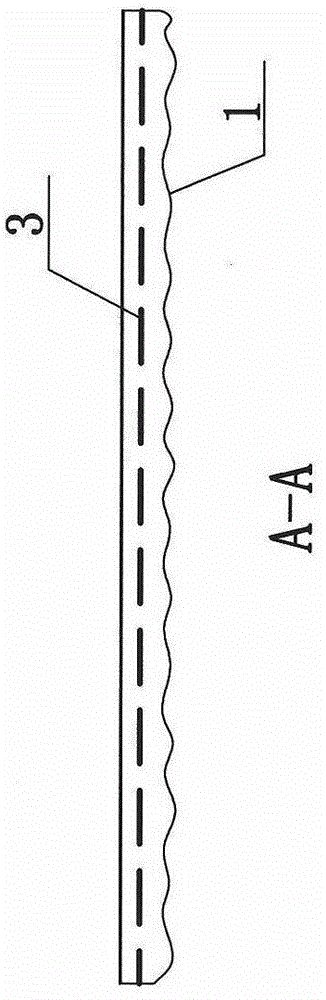

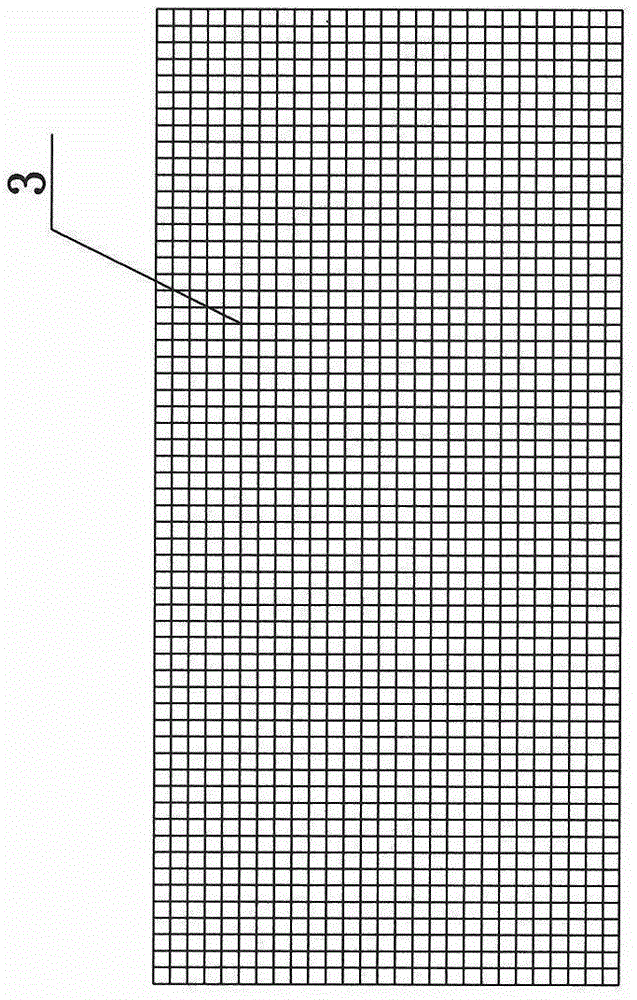

[0028] Such as figure 1 with figure 2 The cement decorative board shown is equipped with such image 3 The steel wire mesh 3 shown is prefabricated with a three-dimensional decorative pattern 1 on the outer surface; metal pendants 2 are pre-embedded on the upper and lower end surfaces of the cement decorative board at a certain interval.

[0029] The cement decorative board adopts the molding process of dry and hard mixture and vibration pressure, and adopts the following molding method to form and produce:

[0030] 1) Forming mold

[0031] Such as Figure 4-Figure 6 As shown, the molding die is composed of three parts: a mobile mold box 4, a molding machine mold box 5 and a molding machine head 6; the mobile mold box 4 is composed of a mold frame 7 and a plastic mold box 8 loaded therein, and the mold frame 7 is in "L"-shaped spacers 9 or "T"-shaped spacers 10 are arranged at the four corners of the plastic mold box 8 to separate and fix the plastic mold box. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com