Sharp operation instrument processing device

A technology for processing devices and sharps, applied in the field of medical devices, can solve problems such as hidden dangers of medical staff, injuries to medical staff, pollution, etc., and achieve the effects of preventing accidental injury, strong adsorption capacity, and improving medical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

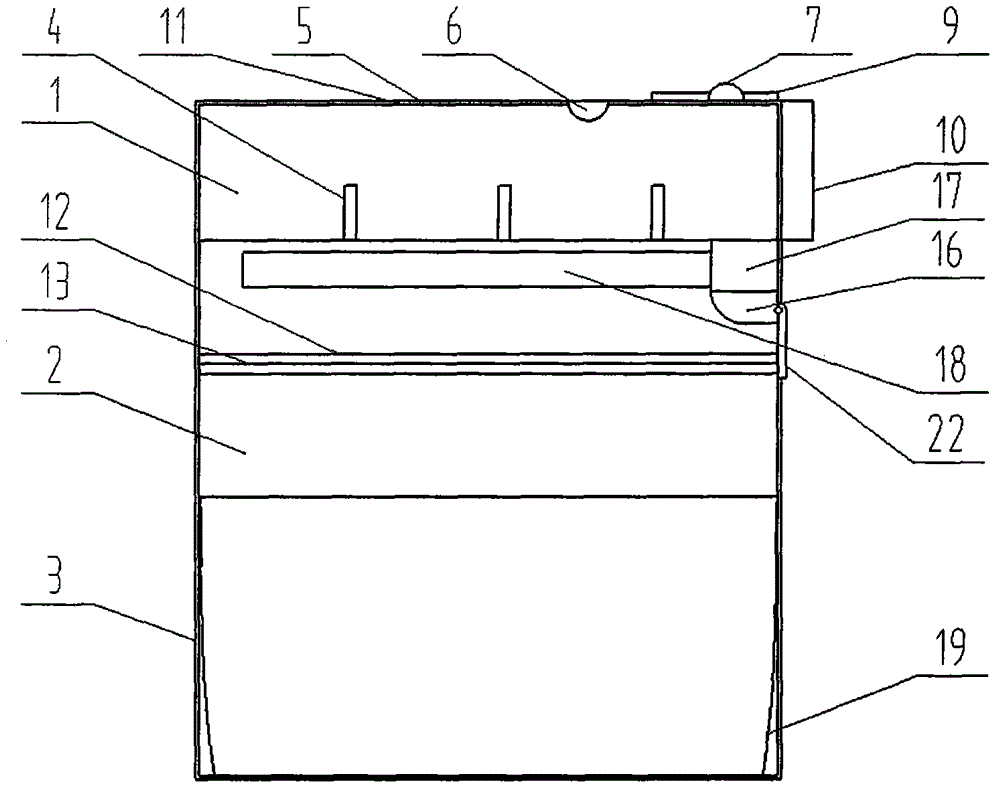

[0024] Such as figure 1 As shown in the figure, the main body of the surgical sharps processing device is a cubic storage cabinet. The interior is divided into a sorting layer 1, a disinfection layer 2, and a storage layer 3 from top to bottom. Cooperate with each other to realize semi-automatic collection of needles and blades during the operation, prevent accidental injuries to relevant personnel, and realize timely disinfection of sharp instruments generated during the operation, effectively improving medical efficiency.

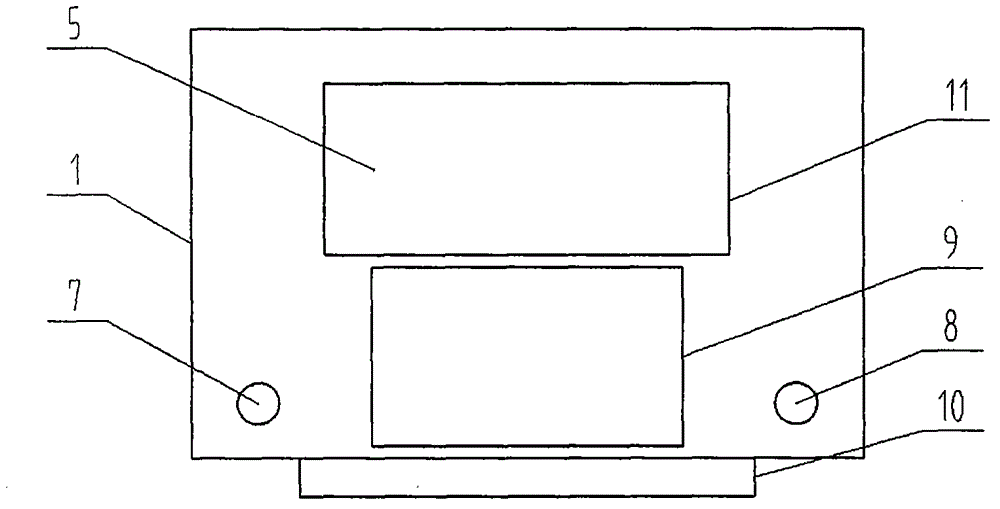

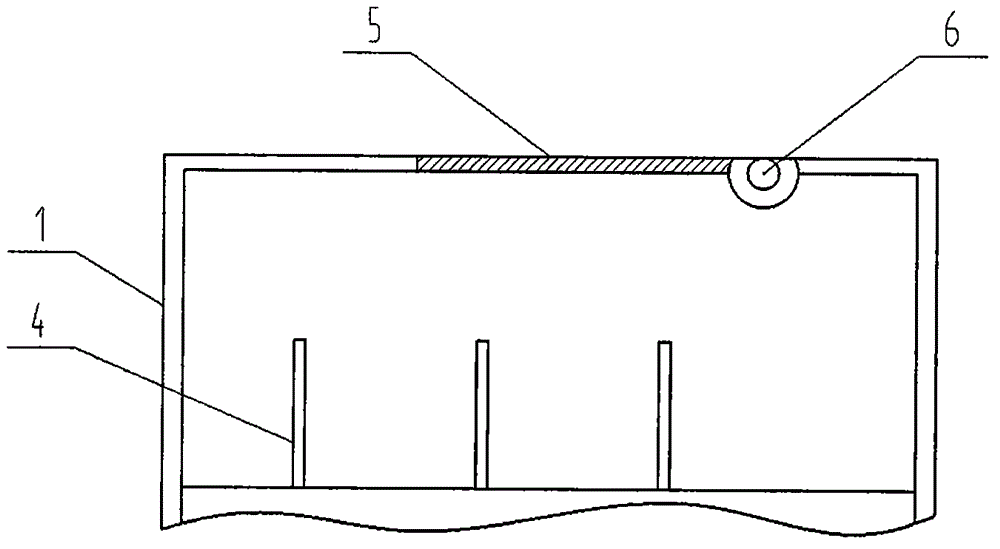

[0025] Such as figure 2 , image 3 The structure of the sorting layer 1 shown is: a cubic box structure, including a partition 4, a guide plate 5, a turning motor 6, a manual button 7, a reset button 8, a countin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com