Double-bucket-wheel opposite type high-speed precise corn seeding device

A seed metering device and precision seeding technology, which is applied to the seed metering device with two rows of scoop wheels on the right and corresponding seed guide wheels, and the left field, which can solve the problems of large seed quantity, low productivity, uncontrollable seed quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

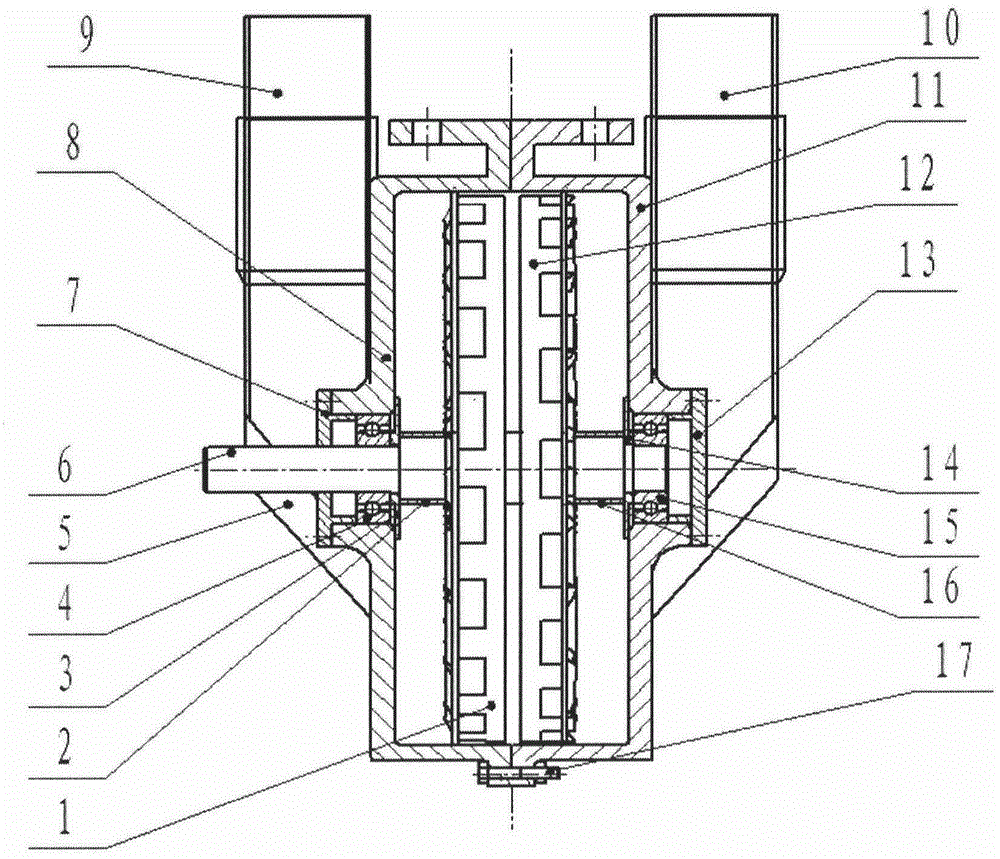

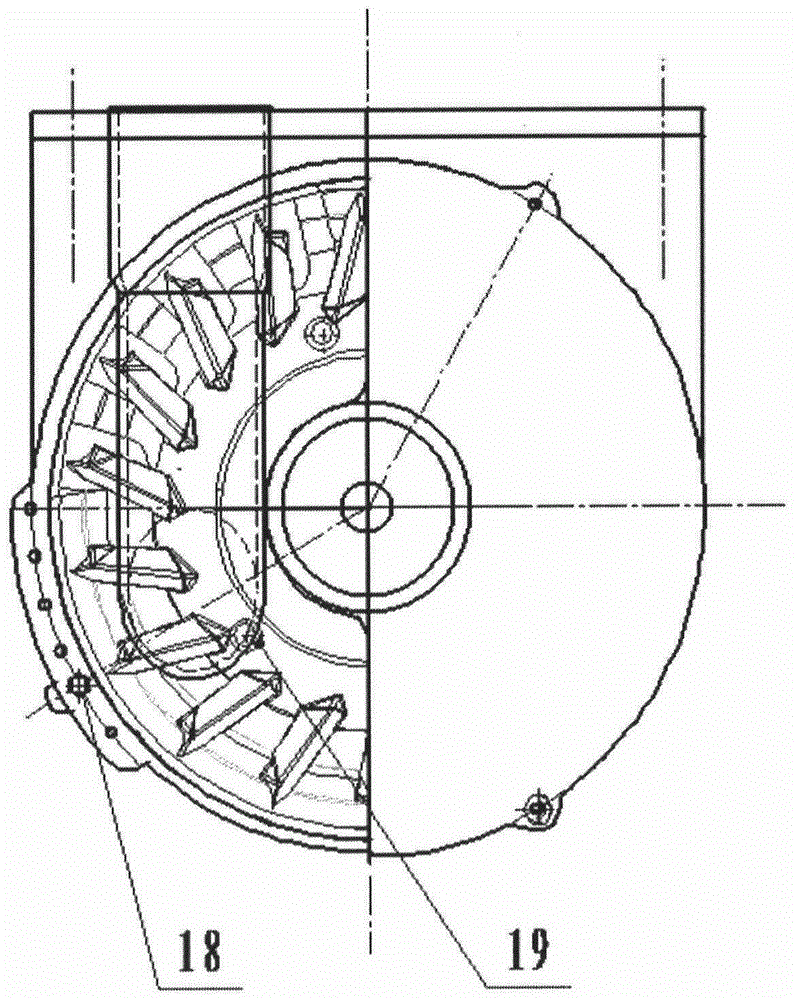

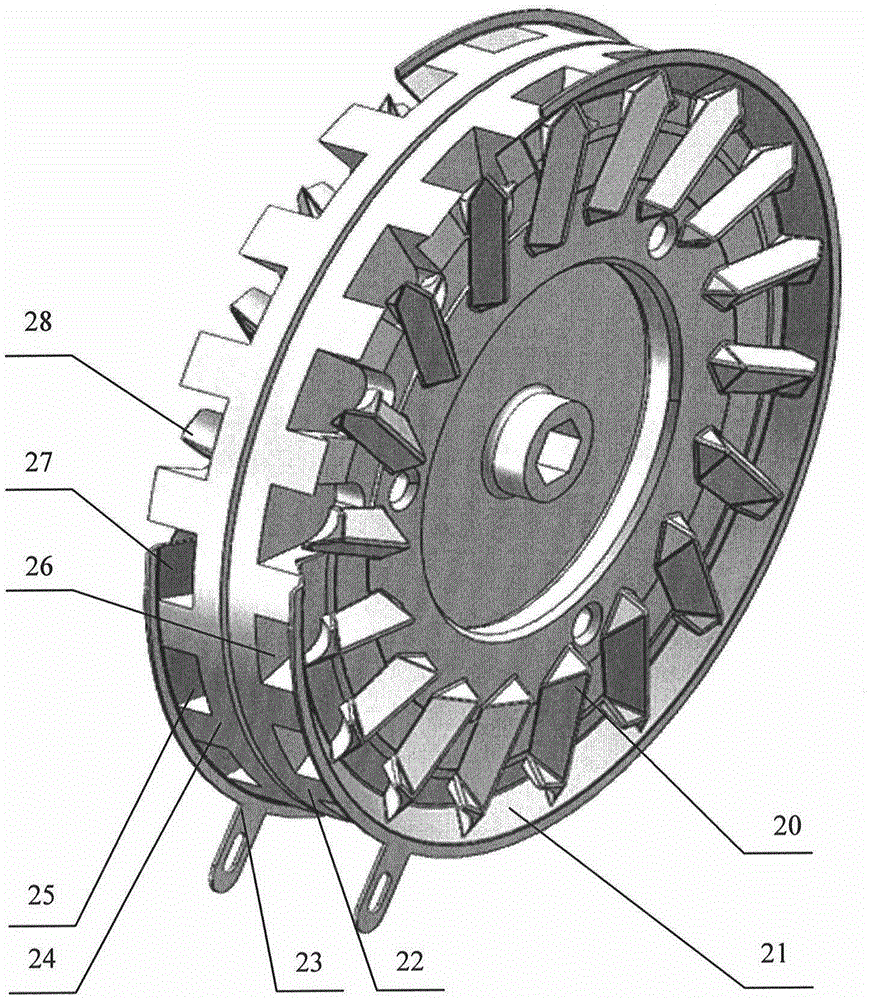

[0013] Embodiment 1: The double-spoon-wheel opposed high-speed corn precision metering device includes: the left cast half shell 8 and the right cast half shell 11 are integral seed metering device housings composed of fastening bolts 18, and the row The seed device housing is a split structure, fixed on the frame, and the left seed metering device assembly 1 and the right seed metering device assembly 12 are housed in the housing. The seed meter assembly is connected as a whole by the seed meter shaft 6, the left and right seed meter assemblies are connected as a whole, the middle is positioned by the steps on the seed meter shaft, and the left seed meter assembly 1 and the right seed meter assembly are respectively connected outwards on both sides. The seed meter assembly 12, the outside of the left seed meter assembly 1 and the right seed meter assembly 12 are axially positioned by the positioning devices 2 and 16, and the left and right seed meter assemblies are connected a...

Embodiment 2

[0016] Embodiment 2: the opening of the seed inlet on the transparent housing is opened upwards, and there are upper and lower openings on the transparent movable seed inlet joint 9 and the left inoculation tube 30, and the different holes on the two are connected with cotter pins 29, and the transparent movable inlet The height of the lower edge of the seed adapter 9 changes to change the amount of seed feeding, and the transparent movable seed feed adapter 9 moves upward, so that the amount of seed feeding increases and the seed surface improves.

[0017] Beneficial effect:

[0018] 1. Since the two sets of scoop wheels are staggered for seeding, when the rotation speed of the seeding scoop wheel and the seed guide wheel are constant, and the hole distance is constant, the working speed can be doubled, and the productivity can be doubled. Fertilizer is applied at the same time, and one opener is reduced for each sowing row, which can greatly reduce the operation resistance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com