Yam bean harvester integrating seedling, digging, collecting and storing,mud removing and straw turnover

A harvester and jicama technology, which is applied to digging harvesters, harvesters, topping machines, etc., to achieve the effects of changing soil structure, reducing energy consumption, and reducing large working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention.

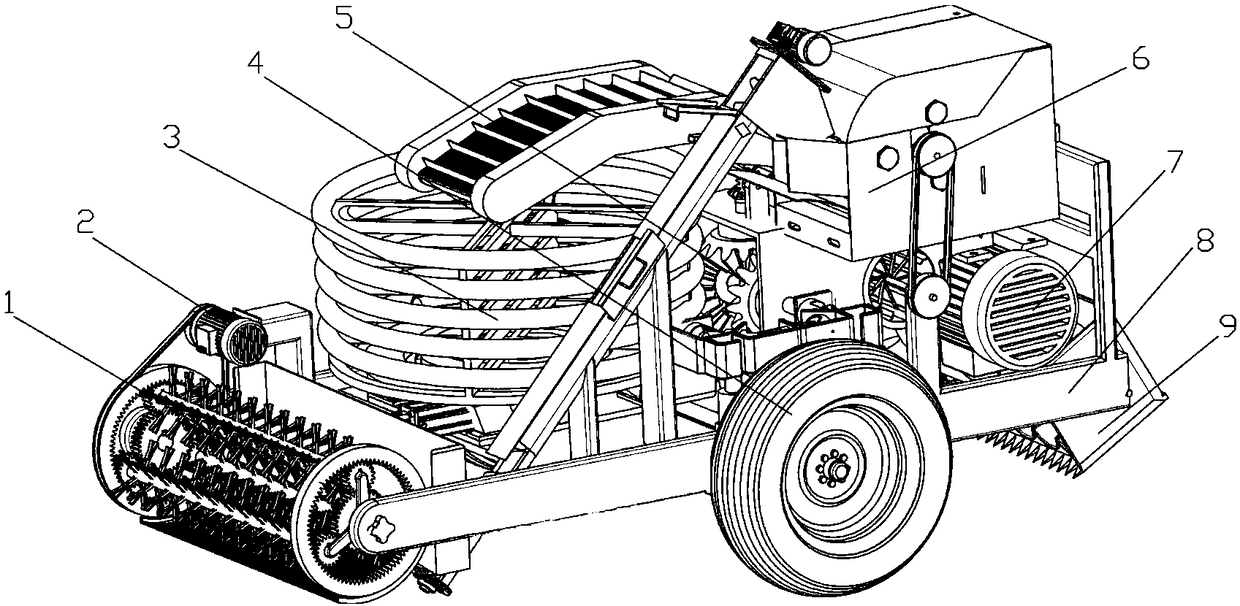

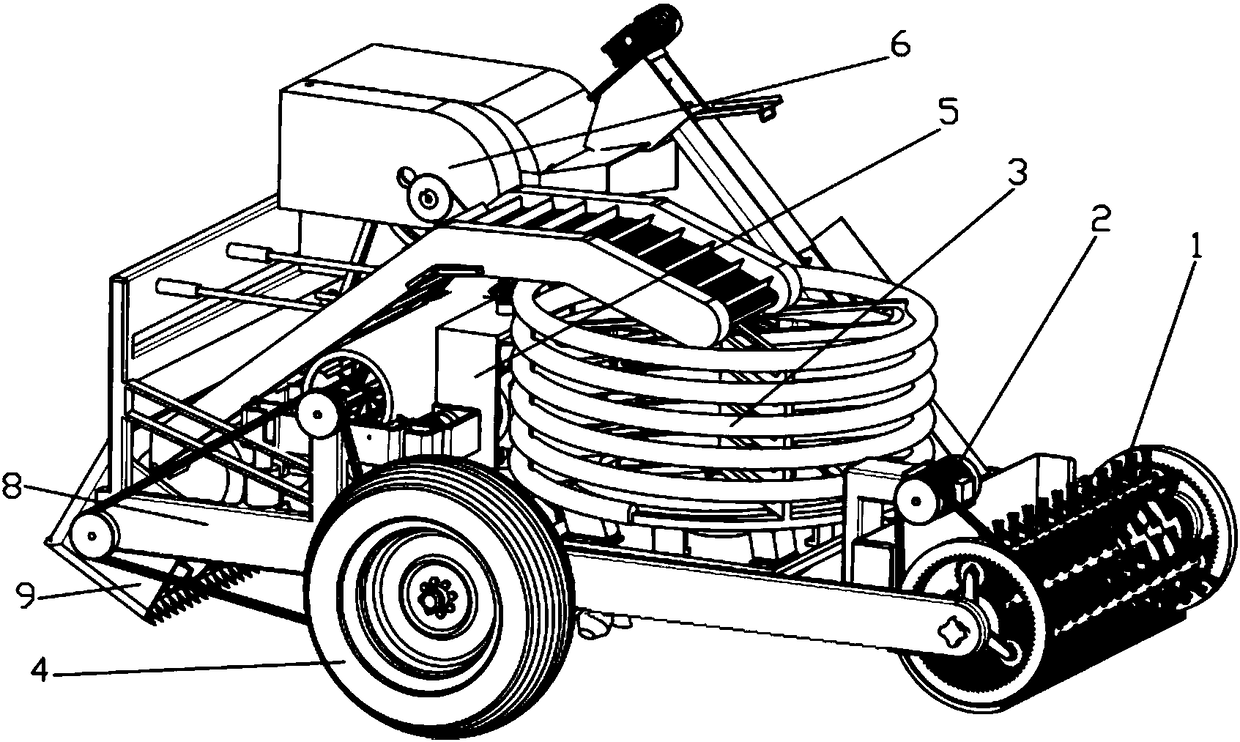

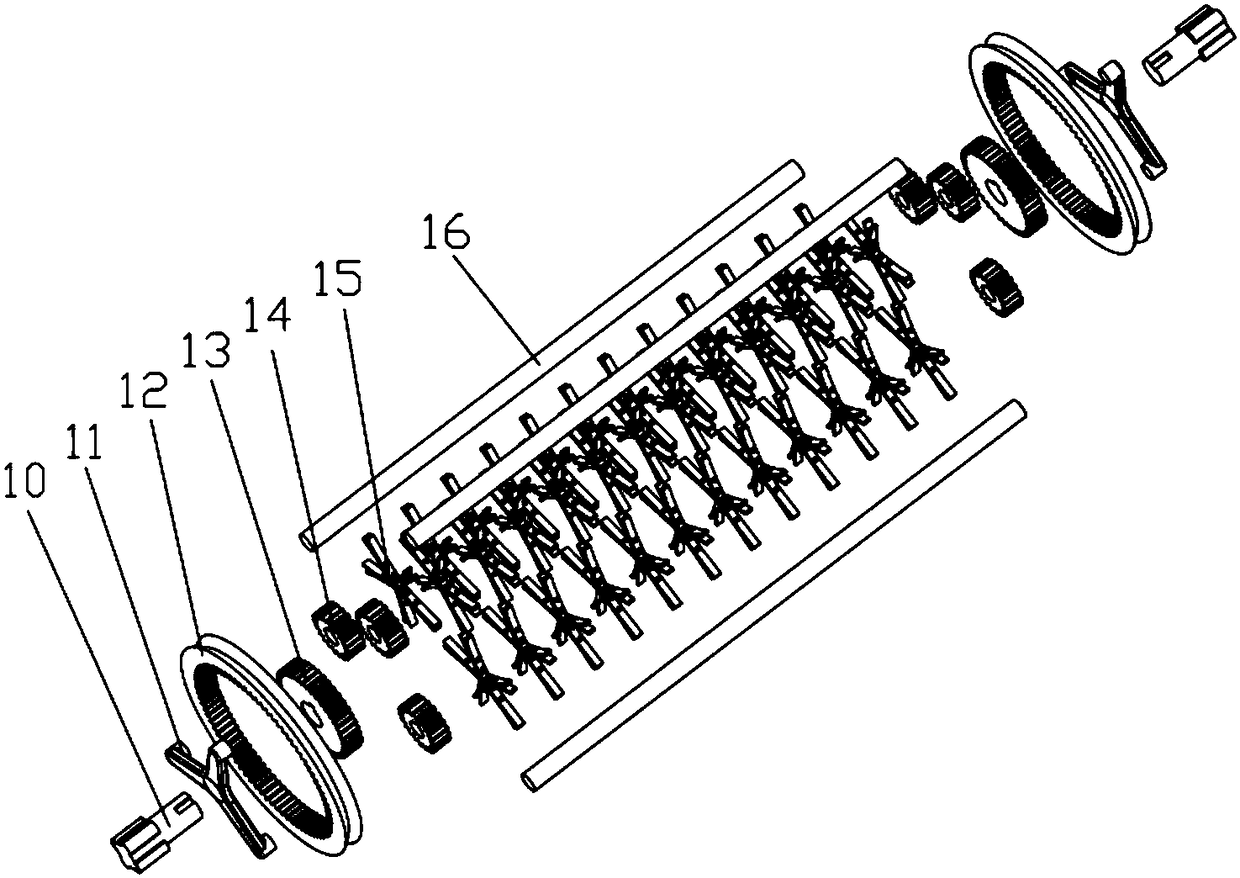

[0040] Such as figure 1 , 2 As shown in and 6, a bean and potato harvester integrating seedling removal, excavation, collection and storage, mud removal, and straw returning to the field is characterized in that it includes a planetary gear seedling remover 1, a motor 2, and a bean and potato harvester. Storage device 3, wheels 4, soil turning device 5, straw returning device 6, motor 2 7, vehicle frame 8, excavating device 9;

[0041] The vehicle frame 8 is a main body support, and the wheels 4 are arranged symmetrically at the left and right ends of the vehicle frame 8, and the planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com