Anti-overflow sealed bearing loading and detecting cable

A technology for detecting cables and preventing overflow. It is applied in the direction of insulated cables, cables, circuits, etc. It can solve problems such as oil spills and cable bearing capacity reduction, and achieve the effects of preventing corrosion, improving bearing capacity, and increasing friction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

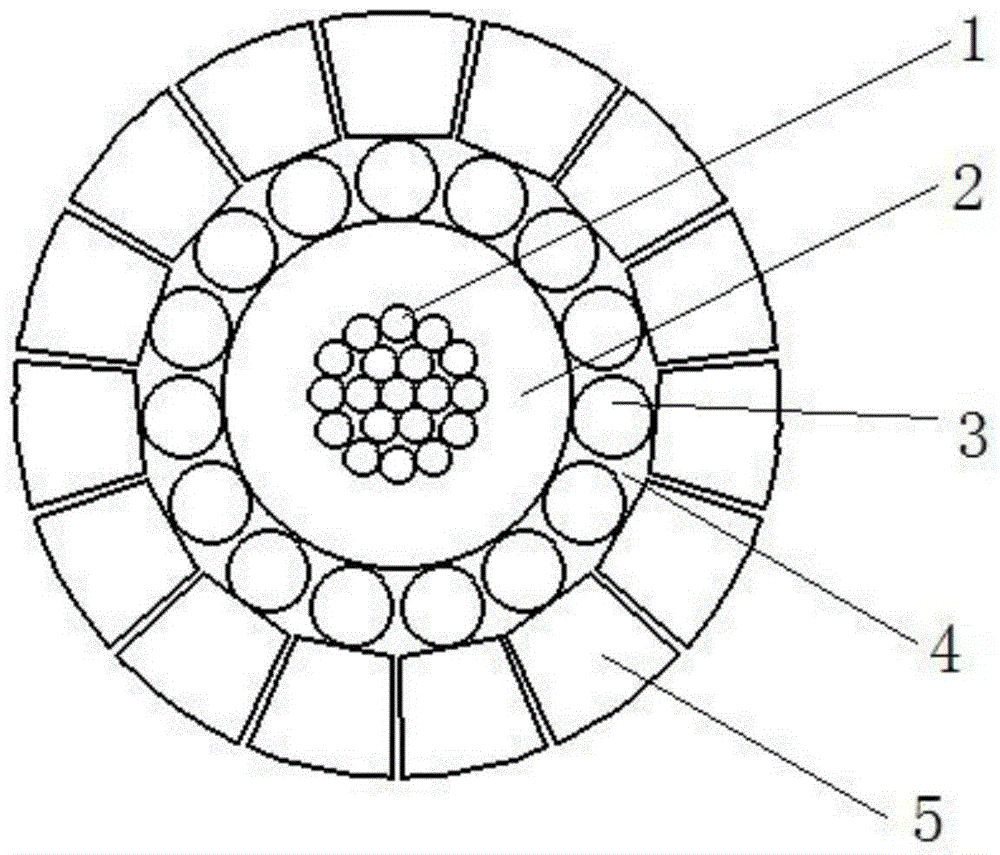

[0035] Embodiment 1: An anti-overflow sealed load-bearing detection cable, its structure is as follows figure 1 and Image 6 As shown, it includes a copper stranded wire 1, the outer ring of the copper stranded wire 1 is covered with an insulating layer 2, the outer ring of the insulating layer 2 is covered with an inner armor layer 3, and the outer ring of the inner armor layer 3 is covered with an outer armor layer 5;

[0036] The inner armor layer 3 is composed of steel wires with a circular cross-section and a sealant layer 4. A plurality of circular steel wires are looped outside the insulating layer 2, and the gaps between adjacent circular steel wires are covered by the sealant layer 4. filled, the sealant layer 4 and the circular steel wire together form a closed structure with a circular cross-section;

[0037] The outer armor layer 5 is formed by a steel wire ring with a fan-shaped ring, and the outer armor layer 5 also forms a ring-shaped airtight structure with a...

Embodiment 2

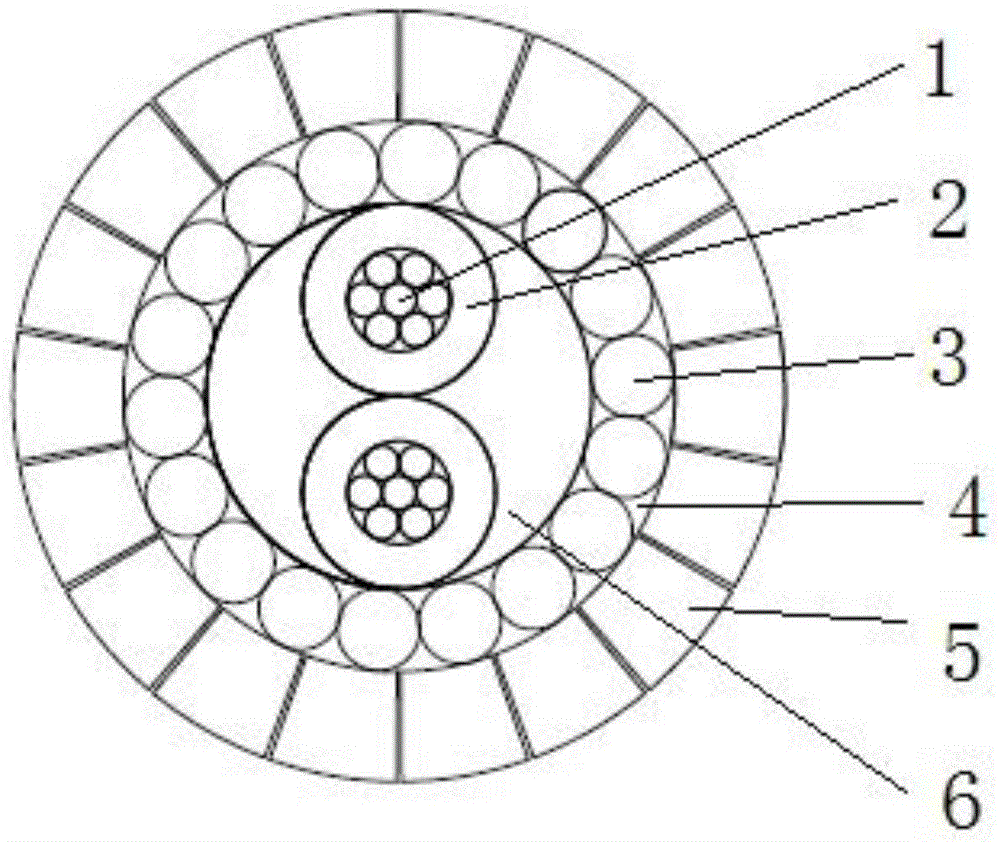

[0046] Embodiment 2: An anti-overflow sealed load-bearing detection cable, its structure is as follows figure 2 and Image 6 As shown, it includes a copper stranded wire 1, the outer ring of the copper stranded wire 1 is covered with an insulating layer 2, the outer ring of the insulating layer 2 is covered with an inner armor layer 3, and the outer ring of the inner armor layer 3 is covered with an outer armor layer 5;

[0047] The inner armor layer 3 is composed of steel wires with a circular cross-section and a sealant layer 4. A plurality of circular steel wires are looped outside the insulating layer 2, and the gaps between adjacent circular steel wires are covered by the sealant layer 4. filled, the sealant layer 4 and the circular steel wire together form a closed structure with a circular cross-section;

[0048] The outer armor layer 5 is formed by a steel wire ring with a fan-shaped ring, and the outer armor layer 5 also forms a ring-shaped airtight structure with ...

Embodiment 3

[0057] Embodiment 3: An anti-overflow sealed type load-bearing detection cable, its structure is as follows image 3 and Image 6 As shown, it includes a copper stranded wire 1, the outer ring of the copper stranded wire 1 is covered with an insulating layer 2, the outer ring of the insulating layer 2 is covered with an inner armor layer 3, and the outer ring of the inner armor layer 3 is covered with an outer armor layer 5;

[0058] The inner armor layer 3 is composed of steel wires with a circular cross-section and a sealant layer 4. A plurality of circular steel wires are looped outside the insulating layer 2, and the gaps between adjacent circular steel wires are covered by the sealant layer 4. filled, the sealant layer 4 and the circular steel wire together form a closed structure with a circular cross-section;

[0059] The outer armor layer 5 is formed by a steel wire ring with a fan-shaped ring, and the outer armor layer 5 also forms a ring-shaped airtight structure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com