Touch point positioning method for self capacitance touch screen

A self-capacitance, positioning method technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve electronic signal noise interference, material differences, affect the stability and control performance of the touch screen sensing system, etc. problem, to achieve the effect of improving accuracy, low calculation amount, and high positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

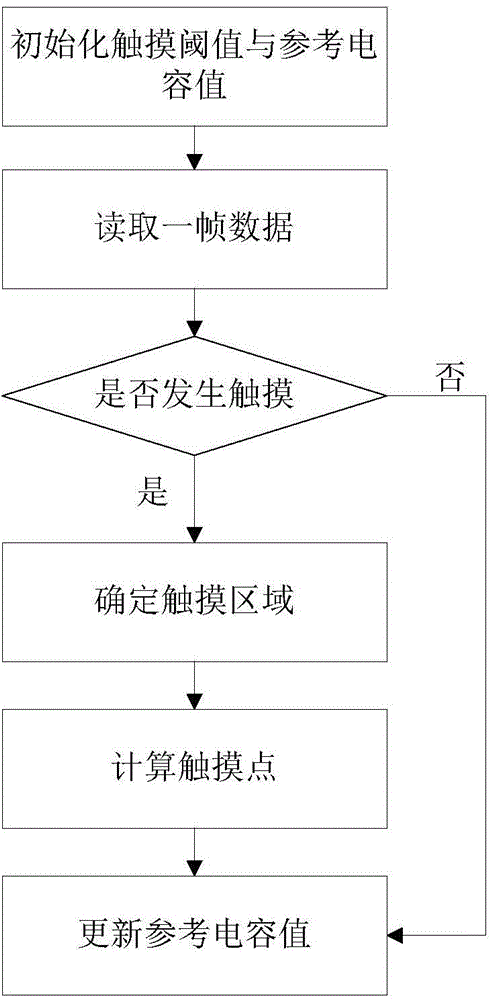

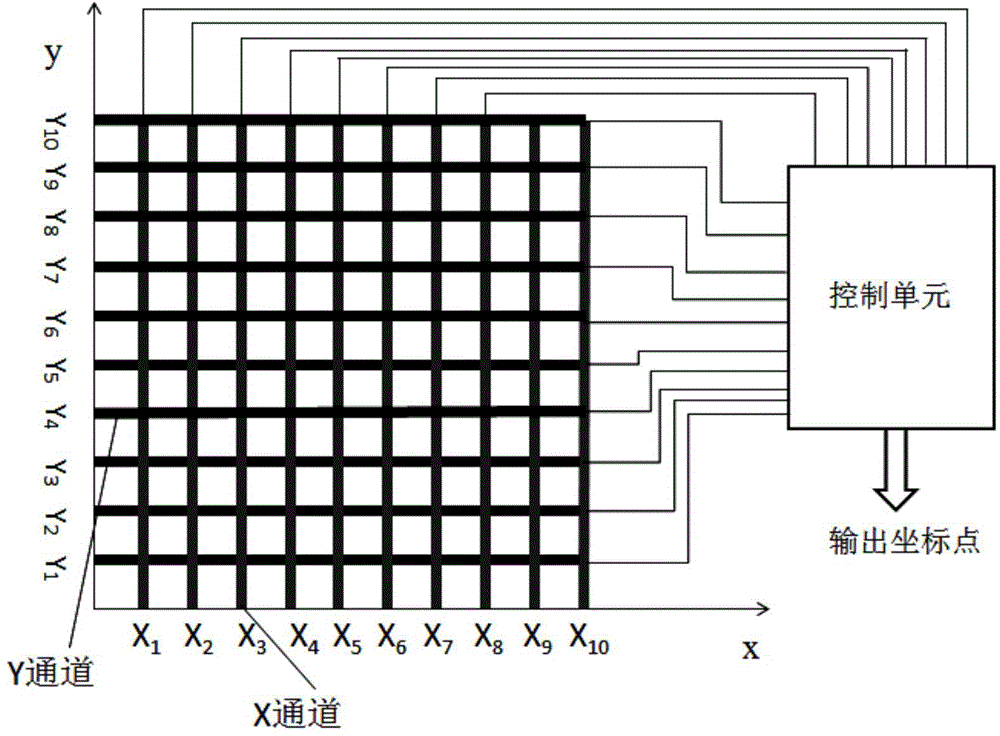

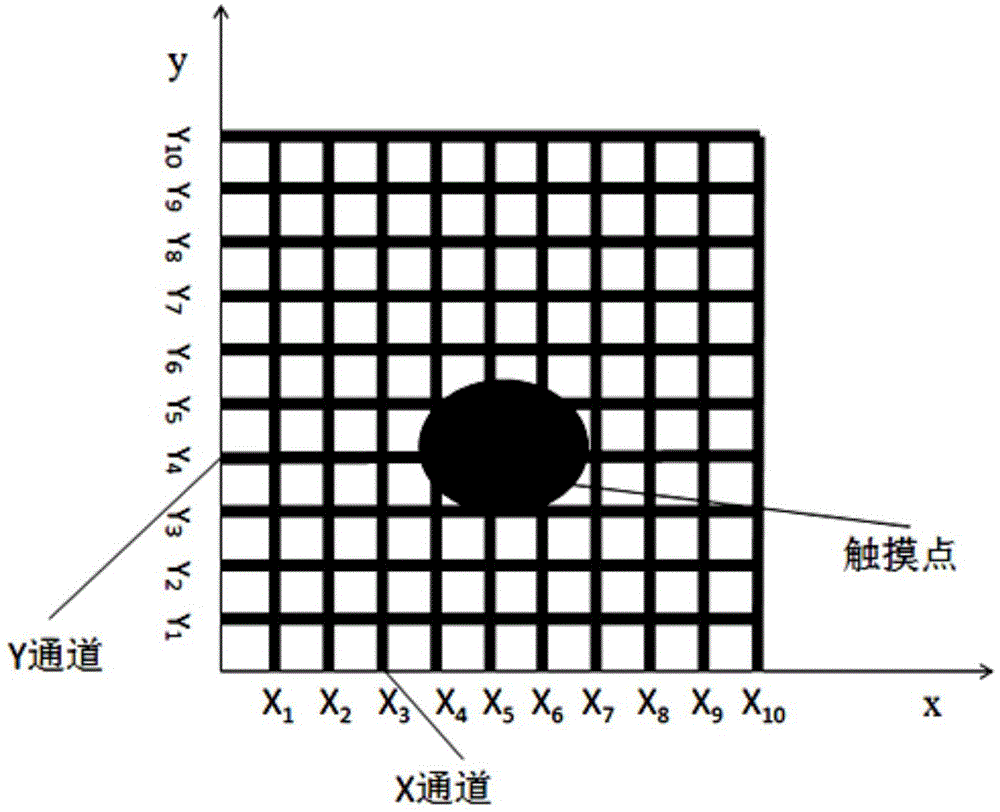

[0080] A method for positioning touch points of a self-capacitive touch screen, referring to figure 2 , the self-capacitive touch screen includes an insulating substrate, a plurality of X-channel electrodes distributed on one side of the insulating substrate, and a plurality of Y-channel electrodes distributed on the other side of the insulating substrate, the distance between the X-channel electrodes and the distance between the Y-channel electrodes The spacing is equal; multiple X-channel electrodes and multiple Y-channel electrodes are connected to the control center through leads, and the control center calculates and outputs touch coordinate points after measuring the capacitance change value of each electrode channel at different times by implementing the touch point positioning method. In this embodiment, the shape of the X-channel electrodes and the Y-channel electrodes is preferably strip-shaped, but actually the shapes of the X-channel electrodes and the Y-channel el...

no. 2 example

[0116] This embodiment uses MATLAB to carry out the simulation experiment on the first embodiment, assuming that the total number of X-channel electrodes is 27, and the total number of Y-channel electrodes is 18, assuming that the real touch point is P=(7, 11.5), where x=7 It means that the real touch point is just on the 7th channel electrode in the direction, and y=11.5 means that the real touch point is in the middle of the 11th channel electrode and the 12th channel electrode in the Y direction. Continuously collect 100 frames of data, respectively use the non-partition method, the partition non-grading method and the classification method proposed by the present invention to calculate the touch point coordinates respectively, and the calculated coordinate points in the X and Y directions are as follows: Figure 7 and Figure 8 Shown, wherein the weighting coefficient ρ of the present invention in the experiment 1 = 0.8, ρ 2 = 0.2. The variance of the average value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com