Uniform oil product mixing device for petroleum analyzing instrument

A technology for analyzing instruments and oil products, which is applied in the field of oil product mixing devices for petroleum analysis instruments, can solve problems such as inconvenient application and complex structure, and achieve the effects of convenient operation and good mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

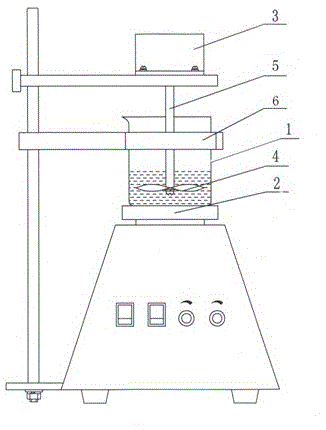

[0013] Embodiment 1: An oil mixing device for a petroleum analysis instrument, comprising an oil storage container 1, a heating block 2 arranged below the oil storage container, and a stirring drive device 3 arranged on one side of the oil storage container. The stirring shaft 5 of the stirring driving device 3 extends into the oil storage container, and the heating block 2 is built with a high-temperature resistance wire, and asbestos is embedded around the resistance wire. The stirring blade 4 is composed of a pair of transverse blades and a pair of longitudinal blades, the transverse blades are fixedly connected to the stirring shaft through a transverse axis, and the longitudinal blades are vertically fixed to the transverse blades through a longitudinal axis. The transverse blade and the longitudinal blade are respectively fixed on the lower end and the middle part of the stirring shaft, and protrusions are arranged on the surface of the transverse blade. The heating bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com