The method of space takeover installation measurement

A space takeover and installation location technology, applied in the field of measurement and testing, can solve the problems of long preparation time for arranging measurement marks and coding marks, increasing manufacturing costs, and long installation time, so as to reduce the difficulty of measurement implementation, reduce measurement costs, and improve installation. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

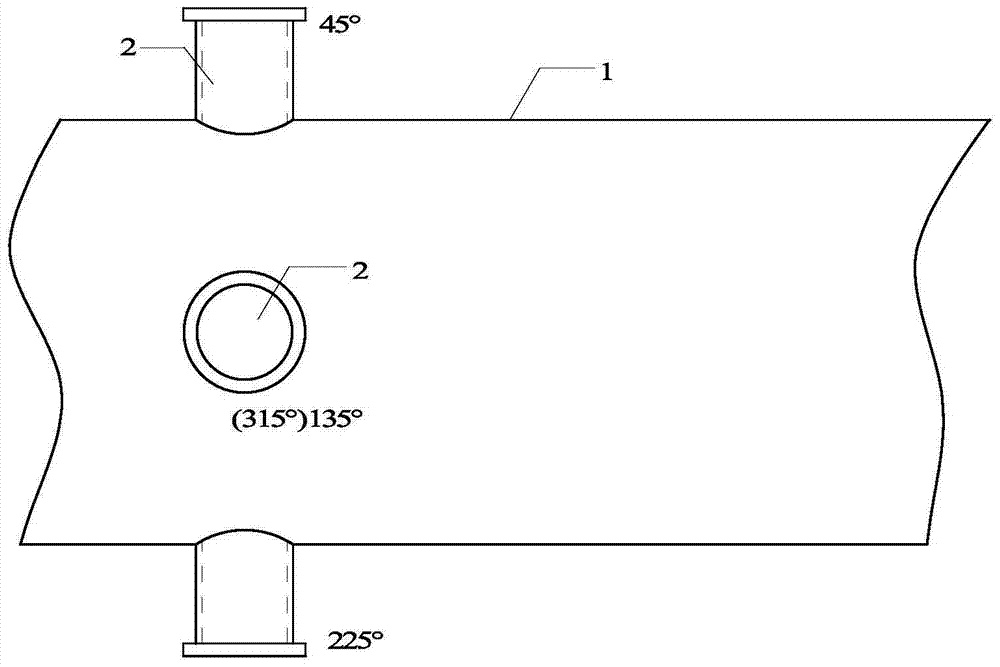

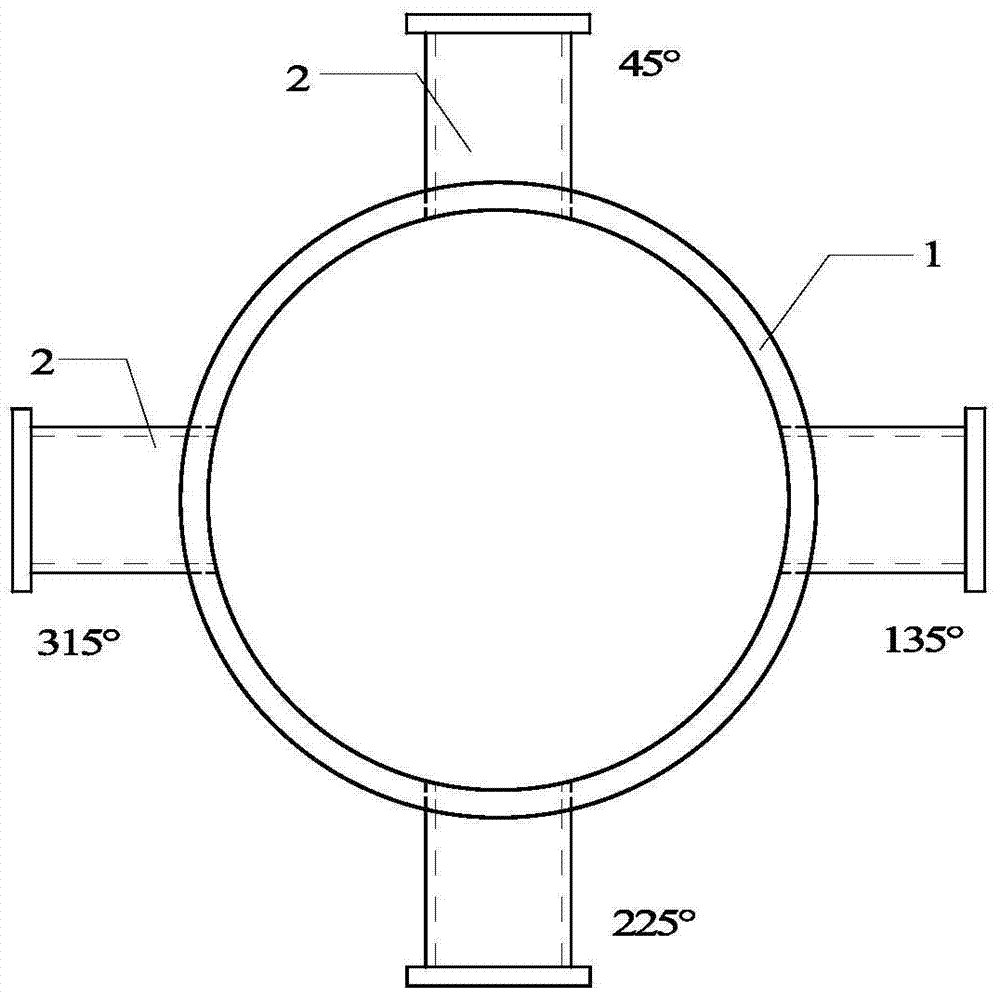

[0027] Such as figure 1 , figure 2 As shown, the four connecting pipes 2 are evenly distributed at equal angles (90°) around the circumference of the cylinder body 1 . The central axes of the four connecting pipes 2 are required to be on the same plane, the flatness is ≤0.5mm, the central axes of the two adjacent connecting pipes 2 are perpendicular and intersect at one point, the verticality is ≤1mm, and the corresponding central axes of the two connecting pipes 2 are on a straight line , coaxiality ≤ 3mm; the central axis of the four connecting pipes 2 is perpendicular to the central axis of the cylinder 1, and the perpendicularity is ≤ 1mm. The installation and measurement process of connecting pipe 2 is as follows:

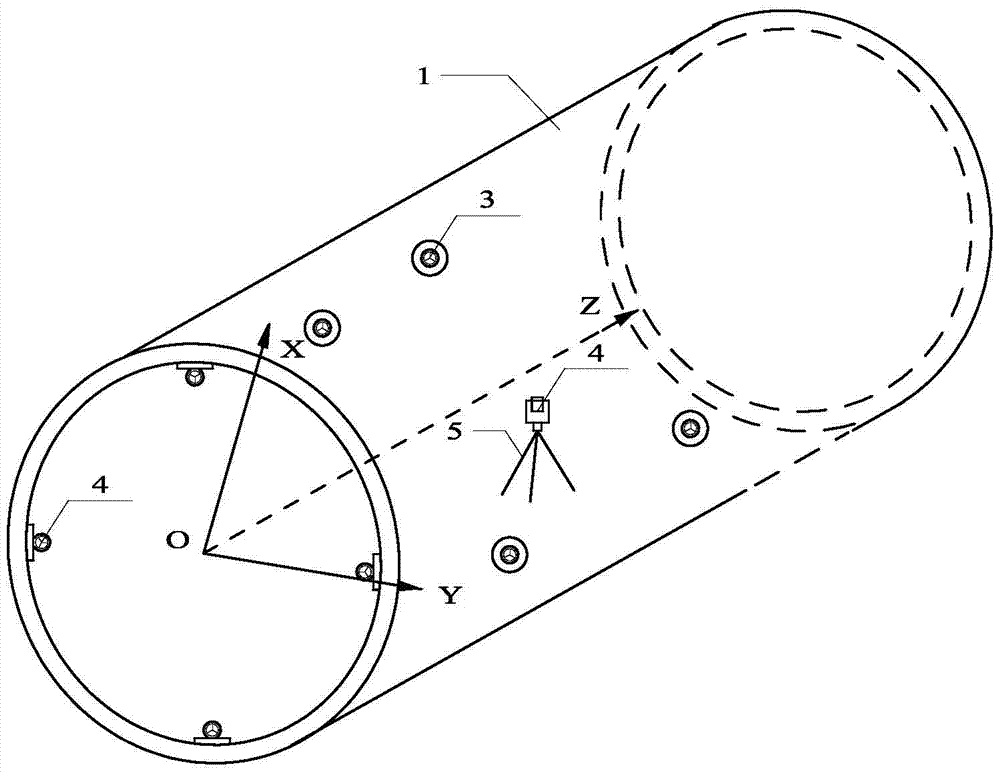

[0028] Step 1, establish cylinder coordinate system:

[0029] During the measurement, according to the sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com