A bridge damping and buffering structure and its manufacturing method

A buffer structure and bridge structure technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of small deformation, waste of materials, and heavy rubber blocks, etc., to reduce mass, reduce beam displacement, and good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

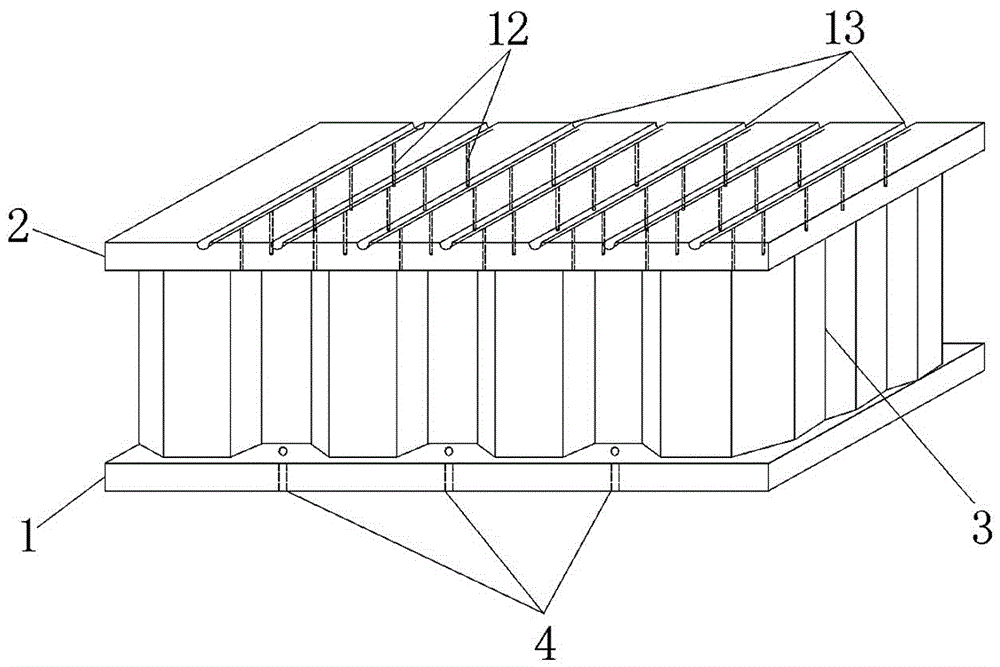

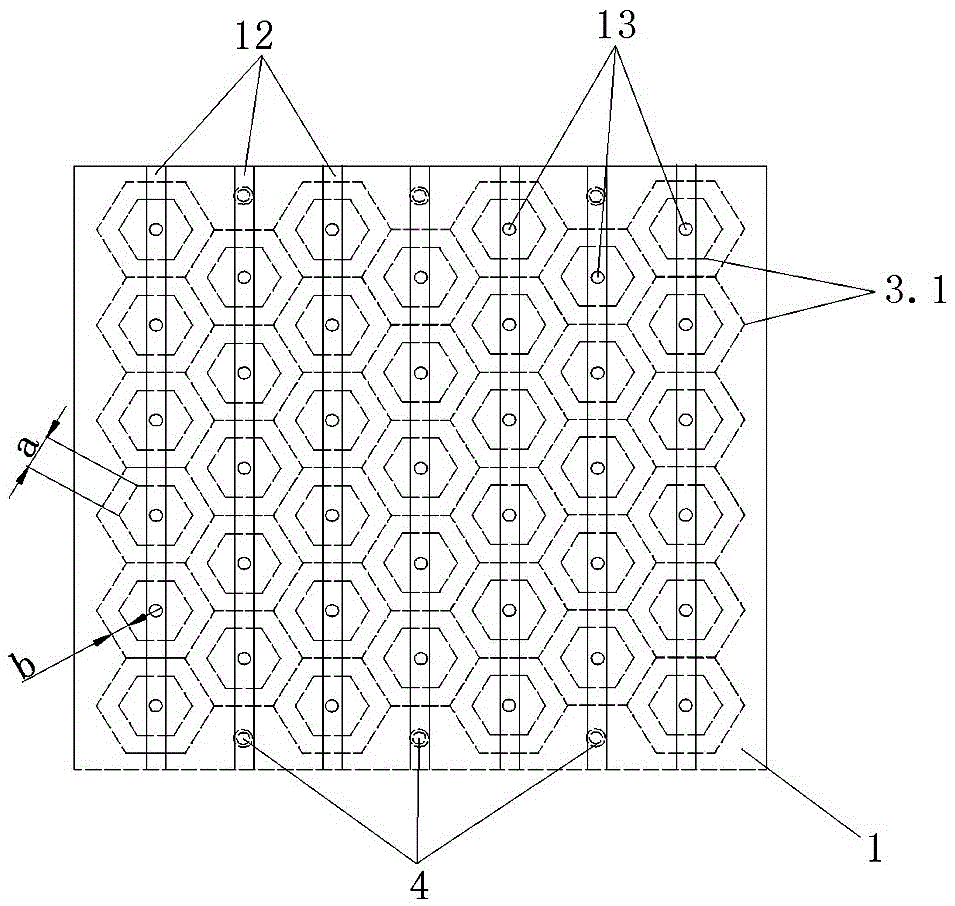

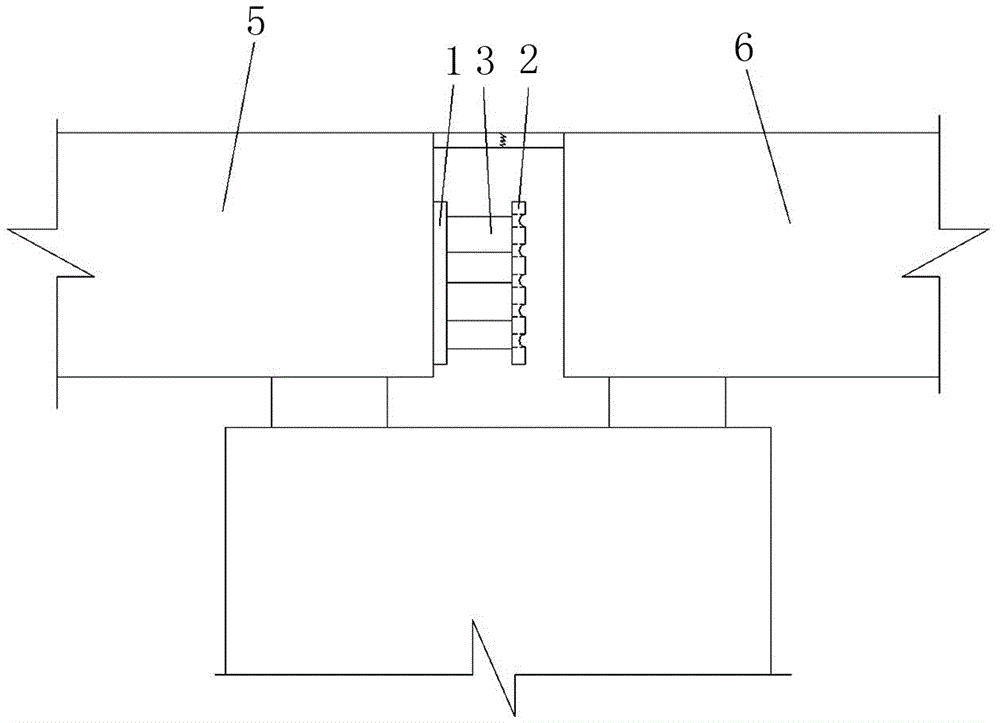

[0045] Example as image 3 As shown, the bridge shock-absorbing buffer structure is fixed between the main beam A5 and the main beam B6 through the anchor hole 4; embodiment two is as follows Figure 4 As shown, the bridge shock-absorbing buffer structure is fixed between the abutment 7 and the main girder C8 through the anchor hole 4; embodiment three is as follows Figure 5 As shown, the bridge shock-absorbing buffer structure is fixed between the main girder D9 and the stopper 10 through the anchor hole 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com