Stain-removal finishing agent for fabric and preparation method of stain-removal finishing agent

A technology for stain treatment and fabric, applied in the field of fabric decontamination treatment agent and its preparation, can solve the problems of affecting the softness of the fabric, old and unsightly surface of the fabric, abrasion, etc., and achieves reduction of pilling and static electricity, and easy industrialization. The effect of simple production and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

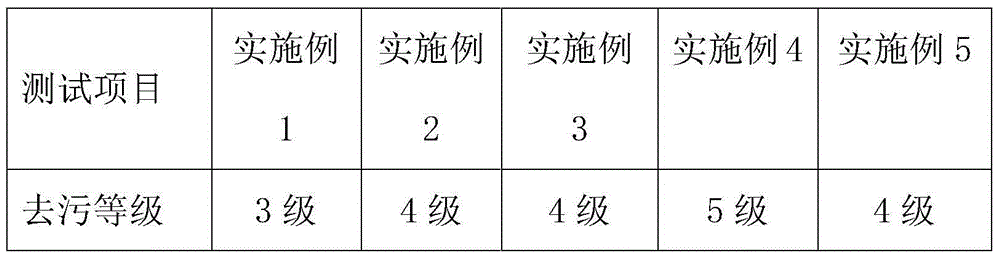

Examples

Embodiment 1

[0029] (1) Mix 35 kg of polyethylene glycol with an average molecular weight of 200 and 100 kg of water evenly, add 5 kg of sorbitol, 2 kg of hydroxypropyl starch sodium phosphate, 0.5 kg of p-chloro-m-xylenol, 0.5 kg of tetrasodium EDTA and trihydroxy Methyl propane 0.3kg, stir evenly with the stirring rate of 80 rev / mins;

[0030] (2) Slowly add 1.8 kg of sodium bisulfate, and stir at 90° C. for 10 minutes to obtain a stain-removing agent for fabrics.

Embodiment 2

[0032] (1) Mix 35 kg of polyethylene glycol with an average molecular weight of 200 and 100 kg of water evenly, add 5 kg of sorbitol, 4 kg of hydroxypropyl starch sodium phosphate, 2.5 kg of p-chloro-m-xylenol, 0.5 kg of tetrasodium EDTA and trihydroxy Methyl propane 0.3kg, stir evenly with the stirring rate of 80 rev / mins;

[0033] (2) Slowly add 1.8 kg of sodium bisulfate, and stir at 90° C. for 10 minutes to obtain a stain-removing agent for fabrics.

Embodiment 3

[0035] (1) Mix 42 kg of polyethylene glycol with an average molecular weight of 600 and 125 kg of water evenly, add 7 kg of sorbitol, 4 kg of hydroxypropyl starch sodium phosphate, 2.5 kg of p-chloro-m-xylenol, 1.8 kg of tetrasodium EDTA and trihydroxy Methylpropane 1.1kg, stir evenly with a stirring rate of 150 rev / min;

[0036] (2) Slowly add 2.2 kg of sodium bisulfate, and stir at 100° C. for 25 minutes to obtain a stain-removing agent for fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com