Panel glass of washing machine

A panel glass, washing machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of rigid shape, can not meet customer appearance requirements, etc., to achieve the effect of beautiful shape curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

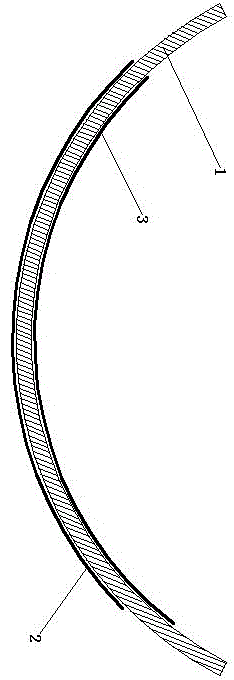

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These accompanying drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so it only shows the configuration related to the present invention.

[0017] Such as figure 1 As shown, a panel glass 1 for a washing machine includes: a curved panel glass 1 and an ink pattern layer printed on at least one side of the panel glass 1. It is characterized in that the inside of the curved structure of the panel glass 1 is coated with high temperature The ink pattern layer 2 or the low-temperature ink pattern layer 3 is printed with the low-temperature ink pattern layer 3 or the high-temperature ink pattern layer 2 on the outside, and the minimum arc length R of the panel glass 1 is 500mm.

[0018] The curved structure panel glass 1 provides a beautiful appearance curve, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com