Mother yarn separation adjusting device

A technology of adjusting device and mother silk, which is applied in the directions of splitting, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of wear and damage, unstable effect, affecting the quality of silk, and ensure the integrity of silk and work. Stable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

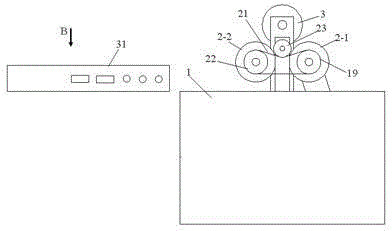

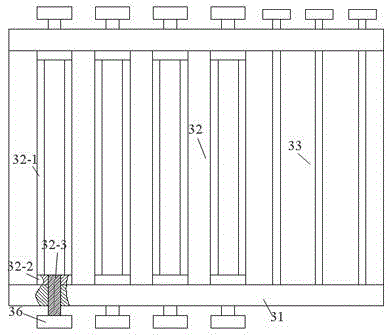

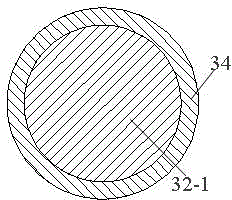

[0021] refer to Figure 1 to Figure 6 , the present invention relates to a mother wire splitting adjustment device, comprising a mother wire splitting frame for splitting the mother wire and a roller adjusting device for subsequently adjusting the tension of the split wires, said mother wire splitting frame includes a groove frame 31 , the groove frame is provided with several screw mandrel groups perpendicular to the wire walking direction, and the screw mandrel group includes a front screw mandrel pair 32 made up of two screw mandrels and a rear screw mandrel 33 made up of a single screw mandrel, The two screw rods of the front screw rod pair are provided with sand chrome coating 34 , and the single screw rod of the rear screw rod is provided with light chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com