Intermediate plate for multi-plate clutch and method for manufacturing intermediate plate

An intermediate plate and clutch technology, which is applied to the intermediate plate for multi-plate clutches and the field of manufacturing intermediate plates, can solve problems such as incorrect ventilation of plate clutches, reduce inertia moment, reduce fuel consumption, and save energy. The effect of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

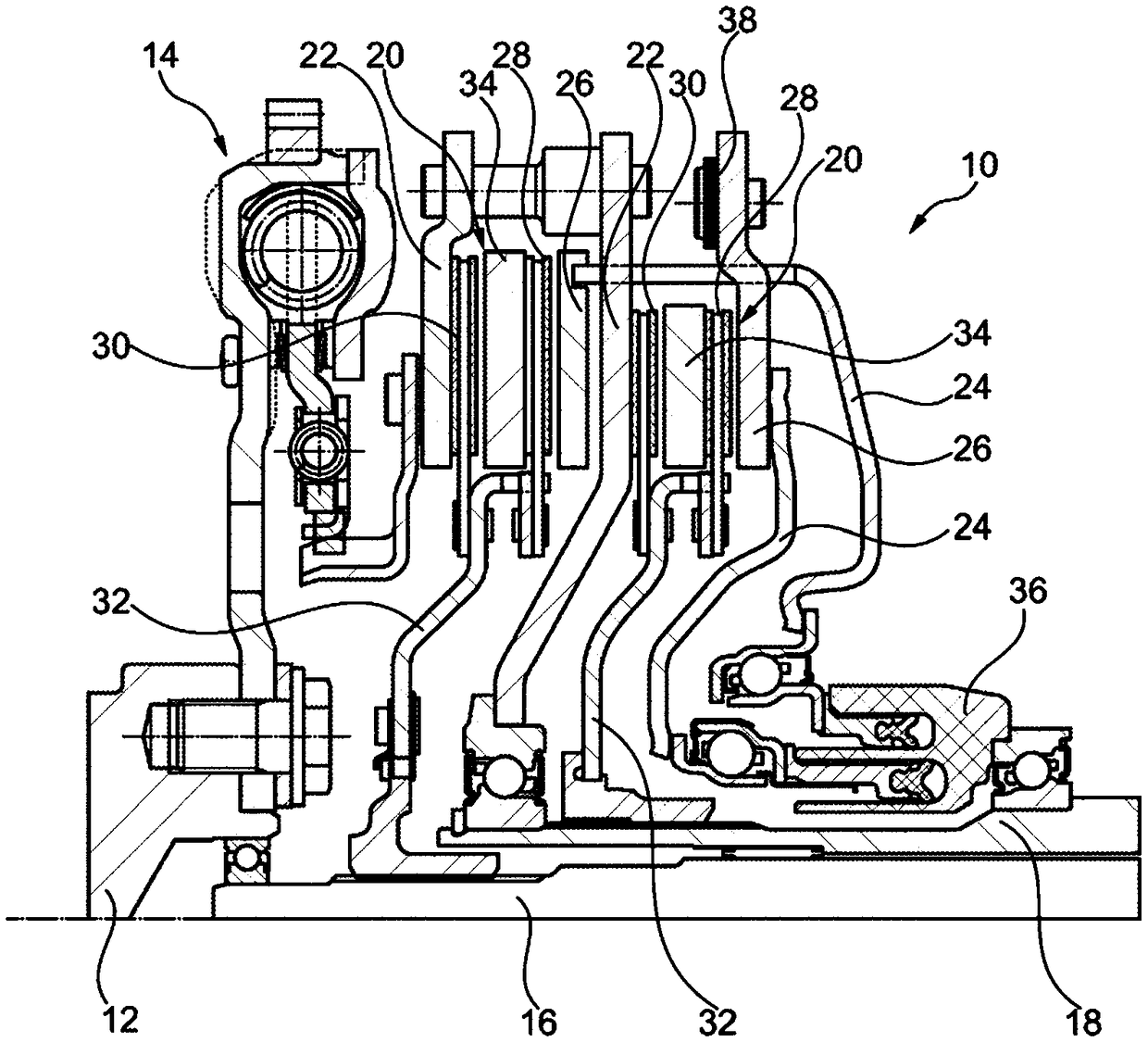

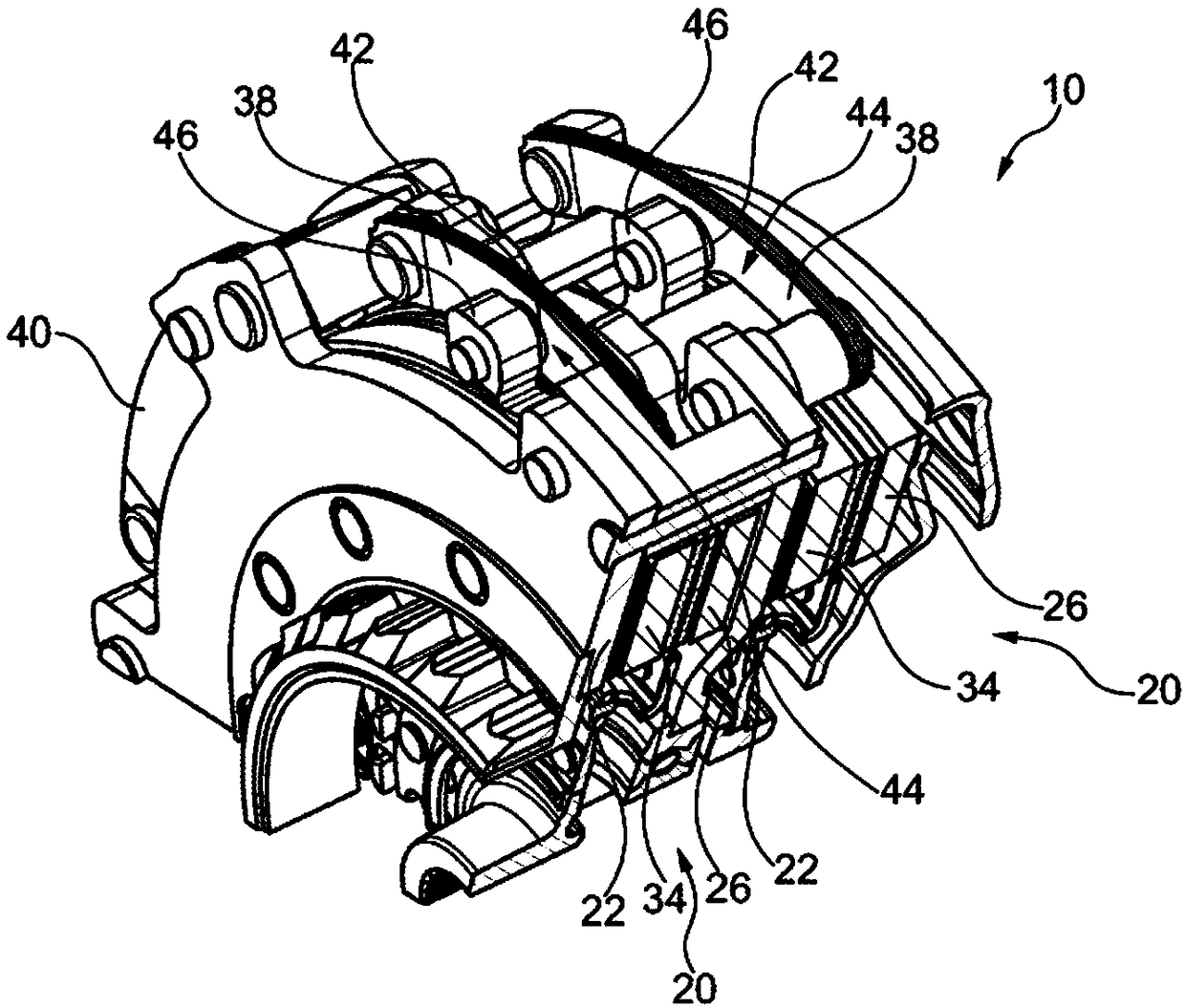

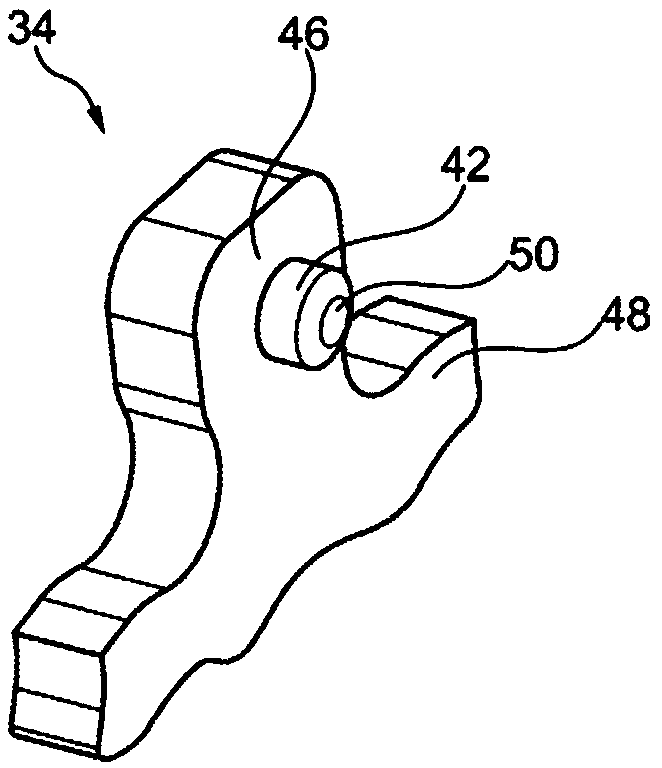

[0035] exist figure 1 The multi-disk dual clutch 10 shown in FIG. 2 is capable of coupling a drive shaft 12 via a torsional vibration damper 14 designed as a dual mass flywheel with a first transmission input shaft 16 and a second transmission input shaft 18 . For this purpose, a multiplate clutch 20 is provided in each case, which each has a counter pressure plate 22 coupled to the drive shaft 12 and a pressure plate 26 which is displaceable by means of an actuating element 24 designed as a rigid actuating pot, wherein The pressure plate 26 is also able to press an intermediate plate 34 which is arranged between the first backing ring 28 of the clutch disk 32 and the second backing ring 30 which is axially displaceable relative to the first backing ring 28 . For this purpose, an actuating force, in particular for closing the multi-plate clutch 20 , can be introduced into the actuating element 24 by the hydraulic actuating system 36 . The pressure plate 26 is connected at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com