Treatment method and device of wastewater containing superfine silicon powder

A technology of ultra-fine silicon powder and treatment method, which is applied in the fields of energy waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. To achieve the effect of short flocculation and sedimentation time, reducing processing pressure and reducing the amount of carry-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

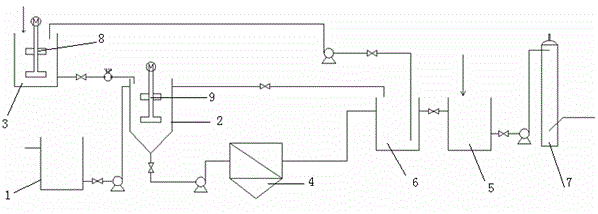

Image

Examples

Embodiment 1

[0030] The method for treating waste water containing ultrafine silicon powder described in the present embodiment is characterized in that, comprising the following steps:

[0031] (1) Collect the wastewater containing ultrafine silicon powder (the particle size of silicon powder is 0.1~1 μm) in the silicon-containing wastewater collection tank 1, and then pass the wastewater containing ultrafine silicon powder into the flocculation sedimentation tank 2;

[0032] (2) Pump the precipitant NaOH solution (20% by mass) from the lye pool 3 into the flocculation-sedimentation tank 2, control the agitator speed to 10r / min; control the pH value of the flocculation-settling tank 2 liquid to 12.81 and The reaction time is 30min to form a supernatant layer and a precipitate layer;

[0033] (3) The upper supernatant layer of the flocculation sedimentation tank 2 enters the alkaline water collection tank 6; part of the alkaline water in the alkaline water collection tank 6 is returned to ...

Embodiment 2

[0040] The method for treating waste water containing ultrafine silicon powder described in the present embodiment is characterized in that, comprising the following steps:

[0041] (1) Collect the wastewater containing ultrafine silicon powder (the particle size of silicon powder is 0.1~1 μm) in the silicon-containing wastewater collection tank 1, and then pass the wastewater containing ultrafine silicon powder into the flocculation sedimentation tank 2;

[0042] (2) Pump the precipitant NaOH solution (30% by mass) from the lye pool 3 into the flocculation-sedimentation tank 2, control the stirrer speed to 15r / min; control the pH value of the flocculation-settling tank 2 liquid to 12.90 and The reaction time is 60min to form a supernatant layer and a precipitate layer;

[0043] (3) The upper supernatant layer of the flocculation sedimentation tank 2 enters the alkaline water collection tank 6; part of the alkaline water in the alkaline water collection tank 6 is returned to t...

Embodiment 3

[0050] The method for treating waste water containing ultrafine silicon powder described in the present embodiment is characterized in that, comprising the following steps:

[0051] (1) Collect the wastewater containing ultrafine silicon powder (the particle size of silicon powder is 0.1~1 μm) in the silicon-containing wastewater collection tank 1, and then pass the wastewater containing ultrafine silicon powder into the flocculation sedimentation tank 2;

[0052] (2) Pump the precipitant NaOH solution (32% by mass) from the lye pool 3 into the flocculation-sedimentation tank 2, control the agitator speed to 20r / min; control the pH value of the flocculation-sedimentation tank 2 liquid to 13.01 and The reaction time is 90min to form a supernatant layer and a precipitate layer;

[0053] (3) The upper supernatant layer of the flocculation sedimentation tank 2 enters the alkaline water collection tank 6; part of the alkaline water in the alkaline water collection tank 6 is returne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com